-

Please only use these forums for blogs, they are not a discussion forum

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

EBBdude`s : Micro Micra project

- Thread starter EBBdude

- Start date

- Status

- Not open for further replies.

Shaun :

But you will be able to get more info in a bit

Frank :

Hmm , is that your final answer

Lowrider;

Absoluetly right , none of them are optimal at all , but which one gave the most power and were there any disadvantages with it and if in case where in the rpm range ?

Come on the rest of you guys,,,,lets have some opinions

But you will be able to get more info in a bit

Frank :

Hmm , is that your final answer

Lowrider;

Absoluetly right , none of them are optimal at all , but which one gave the most power and were there any disadvantages with it and if in case where in the rpm range ?

Come on the rest of you guys,,,,lets have some opinions

pjg1979

THIS IS MY BOOMSTICK!

Well to be honest with you I would give an opinion but I'm learning alot and very impressed with this blog, also not very mechanical minded. lol.

Come on the rest of you guys,,,,lets have some opinions

Shaun :

But you will be able to get more info in a bit

Frank :

Hmm , is that your final answer

Lowrider;

Absoluetly right , none of them are optimal at all , but which one gave the most power and were there any disadvantages with it and if in case where in the rpm range ?

Come on the rest of you guys,,,,lets have some opinions

Ok, I'll bite. Between the 2 there's not enough to say really in terms of top end performance. As I sad before they are both out in terms of peak power and also in terms of peak torque. K11 engines are best at around 12.8:1, erring towards 13:1 for peak HP. It's too close to call which one would make best peak power as HP falls off quite quickly with increasing AFR's, so the surprise maybe that the green curve actually maked less power, either way it's not optimised so in my opinion is not very noteworthy.

Regarding the biggest 'off' on the curves, I am assuming this is meant to mean the biggest fall off in power compared between the two runs. If this is the case I would be inclined to say that the 2600-2700rpm point in the curves.

Despite the above speculation, as previously stated neither of the curves are optimal, so asking people to guess which is better doesn't really add any value and, as such, these don't really prove anything other than you can set up a car badly in more than one way. It should also be noted that this only considers fuelling and ignition timing does not appear to have been taken into consideration, which is also something which can greatly effect the torque curve on a K11 engine depending on setup.

pjg1979

Everybody learns either way.

Keep an open mind.

@lowrider

You may have discovered that my question was quite simple :

Which one of the 2 graphs gives the highest output ?

"It's too close to call" ,,,you say ?

2 close at which point ?

Wouldnt it be fair to say that in the aerea where you would exspect the highest output of power the AFR is not close at all.

That means that around 5-6000 rpm it is a huge gap from 12 pointsomething to 15 pointsomething .

If that is not enough to make a difference then i dont know...

Of course it is only relative to this beeing 2 different fuel pressures being used on these 2 measurement , nothing else than that is changed. Not ignition curves or likewise.

That you will be able to utilize other ignition curves and other details to make either runs better is not a question at all here...

Everybody learns either way.

Keep an open mind.

@lowrider

You may have discovered that my question was quite simple :

Which one of the 2 graphs gives the highest output ?

"It's too close to call" ,,,you say ?

2 close at which point ?

Wouldnt it be fair to say that in the aerea where you would exspect the highest output of power the AFR is not close at all.

That means that around 5-6000 rpm it is a huge gap from 12 pointsomething to 15 pointsomething .

If that is not enough to make a difference then i dont know...

Of course it is only relative to this beeing 2 different fuel pressures being used on these 2 measurement , nothing else than that is changed. Not ignition curves or likewise.

That you will be able to utilize other ignition curves and other details to make either runs better is not a question at all here...

12.8:1 is theoritical ideal for power. I can say for N/A cars usually around this area also follows true on the dyno.

Micras have so little static compression that ignition timing makes very little difference. +-1 deg on the whole ign table can in some cases be almost unmeasurable, where as on a turbo car this can be 30 bhp.

The biggest gains in a K11 are to be had by increasing the compression ratio and improving breathing. Again seen it all on the dyno many times with K11s now.

My dyno tests have proven that with cams exhaust and intake modifications (essentially all bolt on) stock power can be increased by over 60% which is pretty staggering. This is still maintaining stock compression ratio, and with no internal work at all. There is still also much more to be gained. I would expect with engine development and head work an increase of 80-100% could be achieved. Thats 135-150hp from a CG13 engine which IMO is entirely realistic from a nicely built and still tractable bottom end, after all the high revving group A engines made more power still.

Micras have so little static compression that ignition timing makes very little difference. +-1 deg on the whole ign table can in some cases be almost unmeasurable, where as on a turbo car this can be 30 bhp.

The biggest gains in a K11 are to be had by increasing the compression ratio and improving breathing. Again seen it all on the dyno many times with K11s now.

My dyno tests have proven that with cams exhaust and intake modifications (essentially all bolt on) stock power can be increased by over 60% which is pretty staggering. This is still maintaining stock compression ratio, and with no internal work at all. There is still also much more to be gained. I would expect with engine development and head work an increase of 80-100% could be achieved. Thats 135-150hp from a CG13 engine which IMO is entirely realistic from a nicely built and still tractable bottom end, after all the high revving group A engines made more power still.

Here are the 2 corresponding power graphs of the earlier posted AFR / fuel press , graphs :

GREEN = HIGHER FUEL PRESSURE

RED = LOWER FUEL PRESSURE

Simply by increasing the fuel pressure = you will get nearer the AFR that the engine will produce more power from.

Just bu using a adjustable fuel pressure regulator that i showed you.

Lets get back to the Micro Micras fuel curves that has been tested out :

Here is 4 different AFR graphs that correspond to different fuel pressures :

( dont mind the fluctation as that is a total different issue )

Here is the following pressures used :

(all pressures are unregulated , without vacuum reg )

RED graph = 2,8 bar

GREEN graph = ,2 bar

BLUE graph = 4 bar

PINK graph = 2,2 bar

Notice the Pink graphs pressure.

So , since we were at it here comes todays quiz :

WHICH GRAPHS GIVES THE MOST POWER AND WHICH ONE THE SMALLES POWER OUTPUT AND WHICH ONE GIVES THE HIGHEST MPG ?

GREEN = HIGHER FUEL PRESSURE

RED = LOWER FUEL PRESSURE

Simply by increasing the fuel pressure = you will get nearer the AFR that the engine will produce more power from.

Just bu using a adjustable fuel pressure regulator that i showed you.

Lets get back to the Micro Micras fuel curves that has been tested out :

Here is 4 different AFR graphs that correspond to different fuel pressures :

( dont mind the fluctation as that is a total different issue )

Here is the following pressures used :

(all pressures are unregulated , without vacuum reg )

RED graph = 2,8 bar

GREEN graph = ,2 bar

BLUE graph = 4 bar

PINK graph = 2,2 bar

Notice the Pink graphs pressure.

So , since we were at it here comes todays quiz :

WHICH GRAPHS GIVES THE MOST POWER AND WHICH ONE THE SMALLES POWER OUTPUT AND WHICH ONE GIVES THE HIGHEST MPG ?

Shaun

***StaGGeRed***

WHICH GRAPHS GIVES THE MOST POWER AND WHICH ONE THE SMALLES POWER OUTPUT AND WHICH ONE GIVES THE HIGHEST MPG ?

Best MPG - Blue

Most power -Red

Least power - pink

The most MPG will be when the engine is most efficient, not least amount of fuel. AS you go too lean power and efficiency will also drop.

I have to say however that's a terrible fuel curve. You need to get it looked at and run the car properly with the fuel pressure regulator connected, because your supposed fuel pressures mean nothing when the manifold pressure acting on them means their flow rate is not consistent, that's the whole point of the fuel pressure regulator in the first place. I presume too you disconnected the lambda sensor when trying to carry out this test.

Also I don't think people feel the need to be consistently teased with posts all the time. If your trying to say something just post it so others can learn and not get strung along like this is a school lesson. The thread will get far too bloated for reference and much of the irrelevant content will end up being deleted by the moderators.

I have to say however that's a terrible fuel curve. You need to get it looked at and run the car properly with the fuel pressure regulator connected, because your supposed fuel pressures mean nothing when the manifold pressure acting on them means their flow rate is not consistent, that's the whole point of the fuel pressure regulator in the first place. I presume too you disconnected the lambda sensor when trying to carry out this test.

Also I don't think people feel the need to be consistently teased with posts all the time. If your trying to say something just post it so others can learn and not get strung along like this is a school lesson. The thread will get far too bloated for reference and much of the irrelevant content will end up being deleted by the moderators.

Ed :

I do belive that it is not up to you Ed to decide whats relevant or not ?

As far as i can see this is the second time you commented any of my content in my threads and as usual the only thing you do is to critize in a negative manner,,again.

After recieving so many positive comments througout this project , either in my threads or via pm/ mail so far and other posted threads in this forum , i would be humble to say that the case is quite opposite than what you always try to colour it as.

How come every positive comment i get is from other PRIVATE entusiasts, and the ONLY negative one if from a guy with ECONOMICAL MOTIVES AS RUNNING A COMPANY WITHIN THE FIELD

(Read : you ) ???

What are you afraid of here ?

That other Micra entusiasts ACTUALLY will learn something that they ACTUALLY can do themselves after reading the stuff i show them , WITHOUT always having to PAY someone to do the same things as they might be able to learn and do themselves ?

This is my thread and showing my projects progress and it is not up to you to decide wether whats relevant or not,,,thats all i have to say to that

Back to the project guys :

Ok , here is some details of the quiz :

-BLUE graph represents the AFR with the highest power output and also has the highest fuel pressure.

-PINK graph has got the lowest power output BUT i was able to get a 7 % increase in MPG with this used lowered fuel pressure and with normal average driving conditions , without it being to low not to be able to use the car in a normal daily manner...

Next thing i am goint to show a little DIY modification to get some more ompa ompa out of your little Micra engine has got something to do with this little baby

cul8r

I do belive that it is not up to you Ed to decide whats relevant or not ?

As far as i can see this is the second time you commented any of my content in my threads and as usual the only thing you do is to critize in a negative manner,,again.

After recieving so many positive comments througout this project , either in my threads or via pm/ mail so far and other posted threads in this forum , i would be humble to say that the case is quite opposite than what you always try to colour it as.

How come every positive comment i get is from other PRIVATE entusiasts, and the ONLY negative one if from a guy with ECONOMICAL MOTIVES AS RUNNING A COMPANY WITHIN THE FIELD

(Read : you ) ???

What are you afraid of here ?

That other Micra entusiasts ACTUALLY will learn something that they ACTUALLY can do themselves after reading the stuff i show them , WITHOUT always having to PAY someone to do the same things as they might be able to learn and do themselves ?

This is my thread and showing my projects progress and it is not up to you to decide wether whats relevant or not,,,thats all i have to say to that

Back to the project guys :

Ok , here is some details of the quiz :

-BLUE graph represents the AFR with the highest power output and also has the highest fuel pressure.

-PINK graph has got the lowest power output BUT i was able to get a 7 % increase in MPG with this used lowered fuel pressure and with normal average driving conditions , without it being to low not to be able to use the car in a normal daily manner...

Next thing i am goint to show a little DIY modification to get some more ompa ompa out of your little Micra engine has got something to do with this little baby

cul8r

The blue curve made most power because it was closest to where N/A cars make max power at that rpm eg 6K ish, however I suspect the red line made more power between 3-4K rpm since the blue one is far too rich and probably lost around 10% in this area.

Get that line flat across 12.8:1 ish and then the car will be making most power across its whole band (under normal conditions).

Additionally the K11 is mapped in closed loop on a target area of 14.7:1 across its entire map. This is lambda feedback controlled under most conditions but goes out of the window when you start adding mods.

It then gets the stock ecu in to a battle as it tries and fails to maintain a closed loop situation thus causing the flat spots as the AFR base correction factor in the ECU is totally non linear with regards to what the ecu is expecting.

This can be made even worse by adding things like fuel computers eg. SAFC,E-manage etc to try and correct the problem if they are not set up right, most people end up with a setup thats slightly better at best but doesn't solve the problem and additional problems like the acceleration enrichment of the stock ecu can also cause chaos with something like an e-manage, bottom line is its almost impossible to refine without getting within the stock ECU.

Its also worth noting that Dynapak dynos whilst very nice pieces of kit genrally read approx 10% higher wheel power than a Dyno Dynamics dyno, so multiply EBB results by 0.9 to come up with what the same car would do on the dyno I use. This I can add from personal experience by having had cars come to me from Abbey motorsport and then go onto the DD dyno and then reading lower figures. (Its always consistent) the reason is explainded to me by the dyno operators in explaining how DynoDynamics have the losses of the tyres etc as well, were as DynaPack bolt onto the hubs with no tyre friction playing apart.

Get that line flat across 12.8:1 ish and then the car will be making most power across its whole band (under normal conditions).

Additionally the K11 is mapped in closed loop on a target area of 14.7:1 across its entire map. This is lambda feedback controlled under most conditions but goes out of the window when you start adding mods.

It then gets the stock ecu in to a battle as it tries and fails to maintain a closed loop situation thus causing the flat spots as the AFR base correction factor in the ECU is totally non linear with regards to what the ecu is expecting.

This can be made even worse by adding things like fuel computers eg. SAFC,E-manage etc to try and correct the problem if they are not set up right, most people end up with a setup thats slightly better at best but doesn't solve the problem and additional problems like the acceleration enrichment of the stock ecu can also cause chaos with something like an e-manage, bottom line is its almost impossible to refine without getting within the stock ECU.

Its also worth noting that Dynapak dynos whilst very nice pieces of kit genrally read approx 10% higher wheel power than a Dyno Dynamics dyno, so multiply EBB results by 0.9 to come up with what the same car would do on the dyno I use. This I can add from personal experience by having had cars come to me from Abbey motorsport and then go onto the DD dyno and then reading lower figures. (Its always consistent) the reason is explainded to me by the dyno operators in explaining how DynoDynamics have the losses of the tyres etc as well, were as DynaPack bolt onto the hubs with no tyre friction playing apart.

Edit ; thanks for the "thanks " guys

Here is next step in the Micro Micras adventure :

The throttle body itself is from Nissan a quite clever little thing.

Nissan has integrated several details of engine “ management “ into it and will be able to , in a small modified edition , support quite a raise of power output. _Not htat the totally stock OEM throttle body doesnt support more power , its just that it does so in a even better way with a slight surgical procedure

One little detail I found out when I was working on my flow-bench ( Superflow 130 M )is that I has a restriction inside in form of a way to big throttle blade axelshaft which is , when power starts to increase , a “speedbump “ that is unnecessary.

Testing many Micras on my Dynapack has shown a consistent increase in power with a small and swift surgery of its shaft area. Not so much with the subtle increments that the projects steps are into now but more later on as we go along.

This is how :

When we flip our throttle body and see underneath it you will find this:

After some small calculations and some work on the Flowbench i know there is room for improvement.

Look at the actual dimension of the axle shaft itself , framed in red :

This area is restricting the incoming air more than it has needs to and as being in the way of the incoming air-masses it will play a role of how much air that will pass at any given time.

In my works with the Micras I have found that there is small gains in almost whatever you do in the air-path before the throttle blade , in regards to different types of air-boxes , hoses , ducts etc.

Except from a proper inlet “ air-horn “ fed by cold air as shown earlier in the thread.

On the other hand , all the details you can incorporate that will make the incoming air`s work easier after the intake blade makes a huge difference.

Specially with some of the modifiactions that i will show later in the project.

At least if you compare the money spent versus power gained.

It is not uncommon that you would pay 50-100 pounds for something put on before the throttle-body and not getting anything back..

So what I do is simply to make this restriction a little smaller by machining it flatter with a simple die-grinder and you will end up with something like this :

Takes about 1 hours of work and now you can see the difference in available area for the air to pass through.

This is several CFM ( cubic foot pr minute ) more capacity then STD axle and if you want to push some buttons on the calculator, quite a few more square mm in percent of the original area available and that’s what we are after.

Bear in mind that at this level in the project im am only using the OEM throttle body and NOT a bigger one .

That is because i want to show that the OEM will , with this small modification, support substantional increase in power WITHOUT any negative feedback from the process.

After having done many such modified throttle bodies i know its worthwhile.

This modification in conjunction with this little thingy I am making here will be my next test object in the project :

ANYONE FANCY A GUESS OF WHAT IT IS ?

Will show the " thingy " soon and test results of them together soon

To be continued…

Here is next step in the Micro Micras adventure :

The throttle body itself is from Nissan a quite clever little thing.

Nissan has integrated several details of engine “ management “ into it and will be able to , in a small modified edition , support quite a raise of power output. _Not htat the totally stock OEM throttle body doesnt support more power , its just that it does so in a even better way with a slight surgical procedure

One little detail I found out when I was working on my flow-bench ( Superflow 130 M )is that I has a restriction inside in form of a way to big throttle blade axelshaft which is , when power starts to increase , a “speedbump “ that is unnecessary.

Testing many Micras on my Dynapack has shown a consistent increase in power with a small and swift surgery of its shaft area. Not so much with the subtle increments that the projects steps are into now but more later on as we go along.

This is how :

When we flip our throttle body and see underneath it you will find this:

After some small calculations and some work on the Flowbench i know there is room for improvement.

Look at the actual dimension of the axle shaft itself , framed in red :

This area is restricting the incoming air more than it has needs to and as being in the way of the incoming air-masses it will play a role of how much air that will pass at any given time.

In my works with the Micras I have found that there is small gains in almost whatever you do in the air-path before the throttle blade , in regards to different types of air-boxes , hoses , ducts etc.

Except from a proper inlet “ air-horn “ fed by cold air as shown earlier in the thread.

On the other hand , all the details you can incorporate that will make the incoming air`s work easier after the intake blade makes a huge difference.

Specially with some of the modifiactions that i will show later in the project.

At least if you compare the money spent versus power gained.

It is not uncommon that you would pay 50-100 pounds for something put on before the throttle-body and not getting anything back..

So what I do is simply to make this restriction a little smaller by machining it flatter with a simple die-grinder and you will end up with something like this :

Takes about 1 hours of work and now you can see the difference in available area for the air to pass through.

This is several CFM ( cubic foot pr minute ) more capacity then STD axle and if you want to push some buttons on the calculator, quite a few more square mm in percent of the original area available and that’s what we are after.

Bear in mind that at this level in the project im am only using the OEM throttle body and NOT a bigger one .

That is because i want to show that the OEM will , with this small modification, support substantional increase in power WITHOUT any negative feedback from the process.

After having done many such modified throttle bodies i know its worthwhile.

This modification in conjunction with this little thingy I am making here will be my next test object in the project :

ANYONE FANCY A GUESS OF WHAT IT IS ?

Will show the " thingy " soon and test results of them together soon

To be continued…

I cannot see from the picture but you can completely remove the unthreaded side of the spindle and just leave the slimmed side with the machined threads in and reduce the size all the way out to the OD of the inlet tract, then modify some pre countersunk screws to make it as flush as possible. You'll be surprised at the difference in measurable power

Also, please do a test before and after with the coolant lines bypassed around the throttlebody, (removed), as we have never tested this modification and it does seem to make an enjoyable difference, (beware of the idle settings though, as you will need to play around with these a fair bit to make it idle correctly after modification).

I'm assuming you're going to make up an inlet trumpet.....

Also, please do a test before and after with the coolant lines bypassed around the throttlebody, (removed), as we have never tested this modification and it does seem to make an enjoyable difference, (beware of the idle settings though, as you will need to play around with these a fair bit to make it idle correctly after modification).

I'm assuming you're going to make up an inlet trumpet.....

@lowrider

You are absoluetly right about the shafts possibillity as a improvment to get more air into the engine.

I have taken this even a bit further on one of my latest projects by making a “flat-slide “ thingy integrated in a OEM throttle body housing. But this will be showed in a later stage in another project to be presented.

You guessed I made a inlet trumpet,,,,the answer is ; no

Here , some more pictures to get an idea :

First I am turning it in my lathe to get the right diameter and height.

Using a piece of Nylon bolt that was laying around in my garage.

Here it is ready to be machined further and I have clamped it onto my cnc milling machine.

Surely someone will now start to see what it is going to be guys ?

You are absoluetly right about the shafts possibillity as a improvment to get more air into the engine.

I have taken this even a bit further on one of my latest projects by making a “flat-slide “ thingy integrated in a OEM throttle body housing. But this will be showed in a later stage in another project to be presented.

You guessed I made a inlet trumpet,,,,the answer is ; no

Here , some more pictures to get an idea :

First I am turning it in my lathe to get the right diameter and height.

Using a piece of Nylon bolt that was laying around in my garage.

Here it is ready to be machined further and I have clamped it onto my cnc milling machine.

Surely someone will now start to see what it is going to be guys ?

Quick question for Ed. If a modern engine is set by the lambda/injector loop to keep the engine running close to 14.7 to reduce emissions, does it mean that an aftermarket FPR used to increase fuelling slightly (towards 12.8) WILL be a worthwhile upgrade in terms of power gains?

pollyp

Club Member

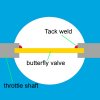

hey ebb, to totally remove the mid section of the throttle shaft, what if the middle of the shaft was cut out leaving only abit of the exposed slotted shaft to support the butterfly valve, tape up the two screw holes on the butterfly, insert the butterfly into the slotted ends of the cut throttle shafts, close throttle to center the butterfly to the TB housing, then tack weld the butterfly to the cut ends of the throttle shafts like illustrated here

@6.5 x 55

i can answer you if you like ; Yes it is worthwhile. Either in closed or open loop but that is another story. As a pure bolt on a FPR as shown WILL give you benefits.

There are also other reasons for putting it on and that i will show later in another project .

.

@pollyp

well , your suggestion is probably ok enough IF you dont get it wrong.

First of all the blade is non-ferrous , that means it is not that easy to just tack weld it on.

Second , IF you sort out some tricky soldering / welding it can make the remaining shaft ends out of line , could twist etc , and make the blade/axels drag/stick that could be a wery dangerous thing to happen.

Next step could be to just make a new blade in weldable material like steel , stainless etc , do as you describe and see if it works.

Personally i would prefer to have a safe solution than a weak , risky one so therefore i just grind it as shown in the picture further up in the thread.

if you want even more gains you can go for a bore-out of the OEM throtthle body and use a BMW blade or a Honda blade Or you can do as i did an make a DTM type slide-blade which will give you 100 % available dia for the air to pass without restrictions.

My approach here in the Micro Micra project is only to show a simple way of improving the OEM throttle body

But hey ;

HAVENT ANYONE YET DISCOVERED WHAT THE NYLON THINGY IS YET ?

i can answer you if you like ; Yes it is worthwhile. Either in closed or open loop but that is another story. As a pure bolt on a FPR as shown WILL give you benefits.

There are also other reasons for putting it on and that i will show later in another project

@pollyp

well , your suggestion is probably ok enough IF you dont get it wrong.

First of all the blade is non-ferrous , that means it is not that easy to just tack weld it on.

Second , IF you sort out some tricky soldering / welding it can make the remaining shaft ends out of line , could twist etc , and make the blade/axels drag/stick that could be a wery dangerous thing to happen.

Next step could be to just make a new blade in weldable material like steel , stainless etc , do as you describe and see if it works.

Personally i would prefer to have a safe solution than a weak , risky one so therefore i just grind it as shown in the picture further up in the thread.

if you want even more gains you can go for a bore-out of the OEM throtthle body and use a BMW blade or a Honda blade Or you can do as i did an make a DTM type slide-blade which will give you 100 % available dia for the air to pass without restrictions.

My approach here in the Micro Micra project is only to show a simple way of improving the OEM throttle body

But hey ;

HAVENT ANYONE YET DISCOVERED WHAT THE NYLON THINGY IS YET ?

Oki , this little “ thingy “ is going to be a spacer between the throttle body itself and the inlet manifold:

The notch on one of the sides has this purpose :

I use a gasket to mark the outlines of the underside of the ”thingy ” :

Make some cutouts for bolts to go through :

Then I mill out the interior of the spacer with a long end mill:

When the interior milling is finished I will use a die-grinder and some grinding flap wheels to sculp it smooth as I want it to get a nice transition from the throttle body into the plenum in the intake.

The single hole in the middle is to be able to utilize the idle-control valves air-passage needs so that is drilled into the spacer.

Now all of the machining is finished and I will mount the spacer onto the manifold and I now need some longer bolts and I just use these that you can pick up cheap at the hardware store for a few pounds:

As gaskets i just use universal gasketmaterial that i will use a small ball-ended hammer to knock out the wanted material. This is a easy way to make any gasket you might need :

Finally I can mount the spacer and check that everything is right :

Looks ok and everything is as planned when assembled into the car

So her it is finished and this spacer will have several purposes as i go along in this project and the first thing a will show is just its use in combination with the modified throttle bodys axel shafts...

So todays quiz is guys :

WHAT HAPPENS WHEN I TEST THE SPACER IN CONJUNCTION WITH THE MODIFIED THROTTLE BODY ?

The notch on one of the sides has this purpose :

I use a gasket to mark the outlines of the underside of the ”thingy ” :

Make some cutouts for bolts to go through :

Then I mill out the interior of the spacer with a long end mill:

When the interior milling is finished I will use a die-grinder and some grinding flap wheels to sculp it smooth as I want it to get a nice transition from the throttle body into the plenum in the intake.

The single hole in the middle is to be able to utilize the idle-control valves air-passage needs so that is drilled into the spacer.

Now all of the machining is finished and I will mount the spacer onto the manifold and I now need some longer bolts and I just use these that you can pick up cheap at the hardware store for a few pounds:

As gaskets i just use universal gasketmaterial that i will use a small ball-ended hammer to knock out the wanted material. This is a easy way to make any gasket you might need :

Finally I can mount the spacer and check that everything is right :

Looks ok and everything is as planned when assembled into the car

So her it is finished and this spacer will have several purposes as i go along in this project and the first thing a will show is just its use in combination with the modified throttle bodys axel shafts...

So todays quiz is guys :

WHAT HAPPENS WHEN I TEST THE SPACER IN CONJUNCTION WITH THE MODIFIED THROTTLE BODY ?

but what is F/A ?

lol ebb, its f### all

That did make me chuckle :blush:.

The only thing I can think of is what Coz said, smoother air flow.

Here you can see what the result was after just putting onto the manifold the modified throttle body and spacer :

(Our last measurement was :50.00 HP / 75.8 Nm ! )

NOW :

52.3 HP and 77,8 Nm

That was a net gain of 2,3 Hp and 2 Nm

A gain throughout the rpm register was noted and not just at the top and more torque lower down.

For the first time the engine now produces power passed 6000 rpms.

-The throttle blade modification gives the engine increased breathing capabillity that will give us even more potensial as we progress with the next levels of tune. The increase / gain in power is not the biggest at this stage of tune but nevertheless an important turn to understand the potensial of increased capacity on breathing.

-The spacer is contributing with more even distribution of air into the manifold / cylinders , giving more torque and helps the engine breathe easier in this state of tune and thereby give us more power.

Plenum volume is important with the layout of the Micra manifold.

The spacer will be even more important later on in another level of tune.

So then , this project started with this :

39,6 HP / 5547 rpm

62,2 Nm / 4098

And now we have :

52,3 Hp / 6127 rpm

77,8 / 3403 rpm

(Note how we now got more torque at lower rpm than std. The spacer is one of the reasons for this )

So the gain we have achieved for now is then :

12,7 HP & 15,6 Nm !

So we have got away with over 12 Hp by simple methods that actually is proven and works everyday in the car.

Will show more soon…

(Our last measurement was :50.00 HP / 75.8 Nm ! )

NOW :

52.3 HP and 77,8 Nm

That was a net gain of 2,3 Hp and 2 Nm

A gain throughout the rpm register was noted and not just at the top and more torque lower down.

For the first time the engine now produces power passed 6000 rpms.

-The throttle blade modification gives the engine increased breathing capabillity that will give us even more potensial as we progress with the next levels of tune. The increase / gain in power is not the biggest at this stage of tune but nevertheless an important turn to understand the potensial of increased capacity on breathing.

-The spacer is contributing with more even distribution of air into the manifold / cylinders , giving more torque and helps the engine breathe easier in this state of tune and thereby give us more power.

Plenum volume is important with the layout of the Micra manifold.

The spacer will be even more important later on in another level of tune.

So then , this project started with this :

39,6 HP / 5547 rpm

62,2 Nm / 4098

And now we have :

52,3 Hp / 6127 rpm

77,8 / 3403 rpm

(Note how we now got more torque at lower rpm than std. The spacer is one of the reasons for this )

So the gain we have achieved for now is then :

12,7 HP & 15,6 Nm !

So we have got away with over 12 Hp by simple methods that actually is proven and works everyday in the car.

Will show more soon…

this very impressive thread dude and i do like it a lot, but I always thought isn't big part of the gain just the simple fact that you are putting new stuff on the car? just like a big big service? cheers

Thank You all for feedback , appreciate it

The idea of this project is as one commented : to try , test and share for everyone to see.

Hopefully also people can perform much of the same stuff that i have.

No spaceage or hightech nonsens perculiarities just plain simple stuff to see for ones own eyes and hopefully fingers to do.

I can not guarentee endless progress but have still a few things to show later on.

This spacer on this particular project was just a prototype one that i worked wery quick on to test some details and get some results from.

I have , on a later project to be shown , made a much more efficient and i would say " smoother " one but all that will be shown and how to make it.

The spacer will also act as a starting point for a alcohol injection system for high torque and even later on a NOS system...

Thanks again for you comments , that makes it even more fun to share

The idea of this project is as one commented : to try , test and share for everyone to see.

Hopefully also people can perform much of the same stuff that i have.

No spaceage or hightech nonsens perculiarities just plain simple stuff to see for ones own eyes and hopefully fingers to do.

I can not guarentee endless progress but have still a few things to show later on.

This spacer on this particular project was just a prototype one that i worked wery quick on to test some details and get some results from.

I have , on a later project to be shown , made a much more efficient and i would say " smoother " one but all that will be shown and how to make it.

The spacer will also act as a starting point for a alcohol injection system for high torque and even later on a NOS system...

Thanks again for you comments , that makes it even more fun to share

Good gains.

They brilliant thing is, all these mods are relatively inexpensive and can be done by the average joe.

I will definently try to carry some of these out in the future.

@ EBB DUDE

Have you done any tests with exhaust manifolds and performance exhaust systems? I was actually thinking of emptying the first catalyst on my standard exhaust to see if it freed up any hp, because i cant afford a full system. lol

Your thoughts? (Y)

They brilliant thing is, all these mods are relatively inexpensive and can be done by the average joe.

I will definently try to carry some of these out in the future.

@ EBB DUDE

Have you done any tests with exhaust manifolds and performance exhaust systems? I was actually thinking of emptying the first catalyst on my standard exhaust to see if it freed up any hp, because i cant afford a full system. lol

Your thoughts? (Y)

yeh ebbdude whats this type of exhaust saying too us

http://www.peterlloydrallying.co.uk/index.php?main_page=product_info&cPath=77_12&products_id=1408

http://www.peterlloydrallying.co.uk/index.php?main_page=product_info&cPath=77_12&products_id=1408

eliot;

You are quite right , it is actually diy stuff indeed

r-reg-sr :

That system looks promising. Will probably be something that i will look into and order back here to Norway for a project.

coz:

Some of the " rally " systems can be quite loud but im not sure how loud such a system will be for a roadgoing car.

I will in not to far future try and make my own system in the MAxi micra project with parts readily available as parts from typically performance shop suppliers.

Have got a sponsor that will give me all the stuff i need

Will share this with pictures and so on when this takes form.

You are quite right , it is actually diy stuff indeed

r-reg-sr :

That system looks promising. Will probably be something that i will look into and order back here to Norway for a project.

coz:

Some of the " rally " systems can be quite loud but im not sure how loud such a system will be for a roadgoing car.

I will in not to far future try and make my own system in the MAxi micra project with parts readily available as parts from typically performance shop suppliers.

Have got a sponsor that will give me all the stuff i need

Will share this with pictures and so on when this takes form.

- Status

- Not open for further replies.

Similar threads

- Replies

- 441

- Views

- 111K