So todays first task of many was to remove the hubs so they can be sent off for machining, making a hybrid hub from N15 and K11 hubs.

Hubs unbolted from strut, Brake lines removed, Track rod cut out ( it was nackered anyway), hub unbolted from the wishbone and hub removed.

Although because of the thread on the ball joint wrecking itself, we are now in need of a new wishbone aswell as a new track rod end. Not that expensive, but cash is tight.

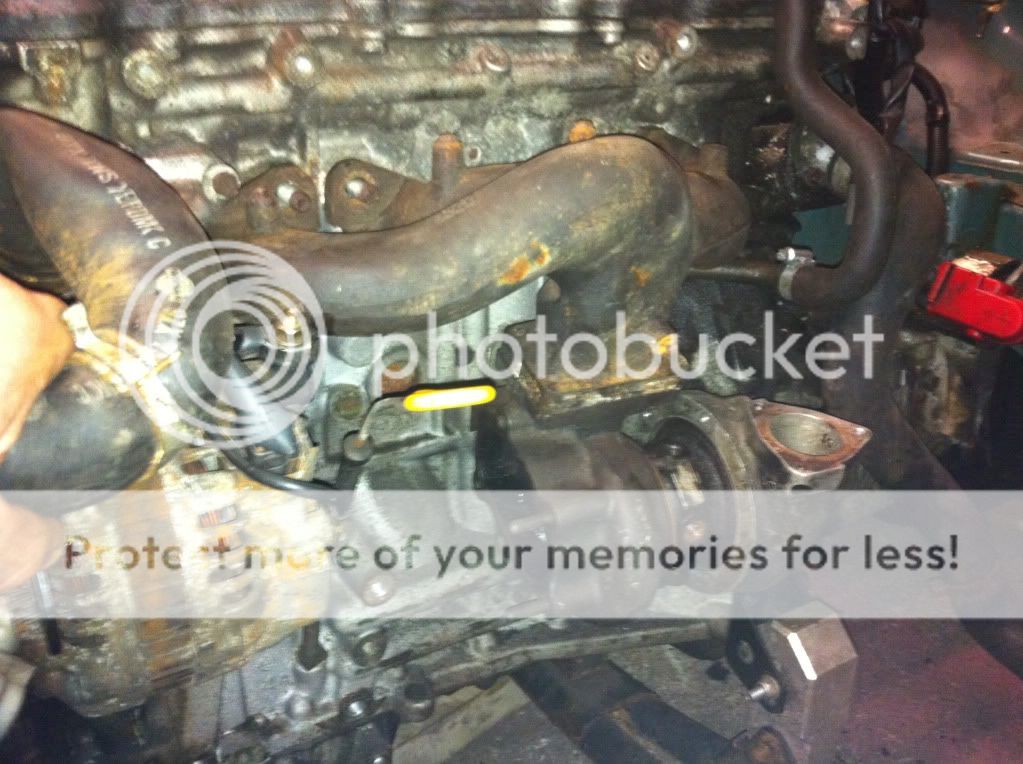

Close up of the removed hub ;

Close up of coilover ;

We are probably going to re introduce the helper spring as its just way too stiff.

Anyway with regards to the hubs, what we plan to do is ;

Have the N15 inner bearing with driveshaft splines machined and pressed in place of the current K11 one.

And also the SR20 driveshafts being shaved down a bit on the diameter to fit into the space in the K11 hub. No pics but a special thanks to Cov for helping with this.

So with that done, moving onto the next task of bodywork. I continued sanding down the rear arch full of filler and ross continued sanding down the drivers door.

And anti rust primer on the wing mirror area ;

Bumpstrip removed ;

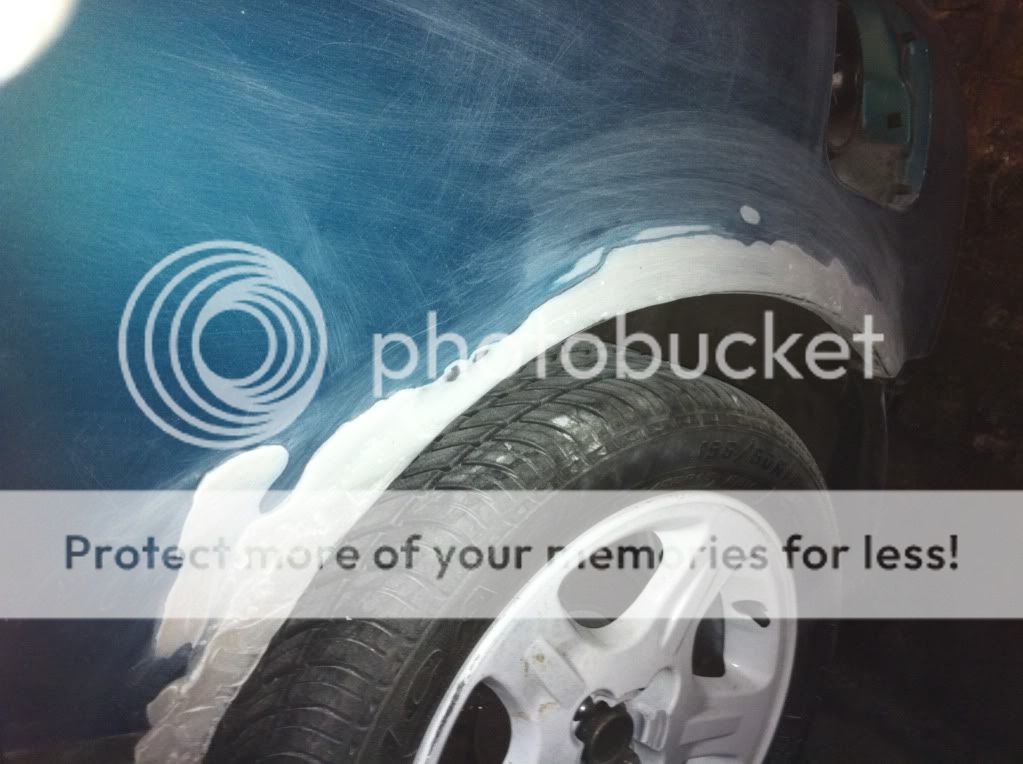

Then out came the compressor and paint,

Yes its only the door been painted for now but the car will eventually all be in this colour. Nissan BS7 Blue. We had a lot of paint left over from previous work.

With that done, time to drop the engine again. Fuel lines disconnected, wiring pushed through the bulkhead. Engine loom disconnected from interior loom. And Engine hoisted out.

So with that done we now need to purchase a driver side wishbone and track rod end. Anyone got one spare? Lol

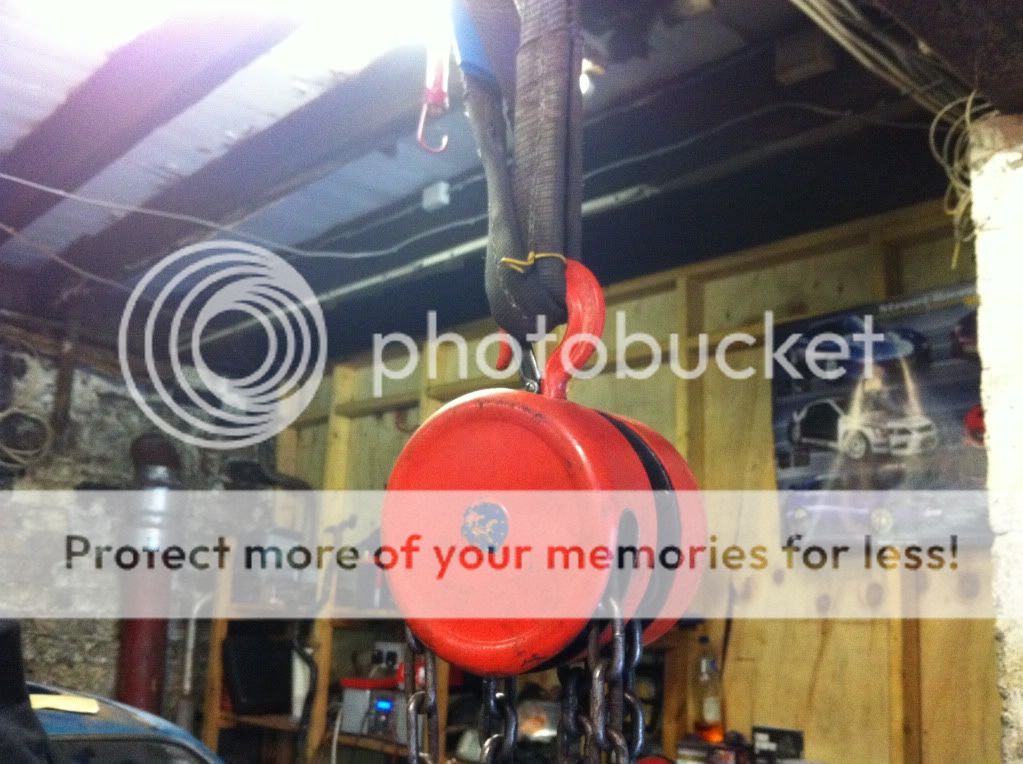

And incase any of you wanted to know what we use an engine hoist ;

Structural beam of the building ;

And a lifting chain connecting to this steel beam via a heavy duty lifting strap and another connected to the engine,

That’s all for now.