Update timeeee :

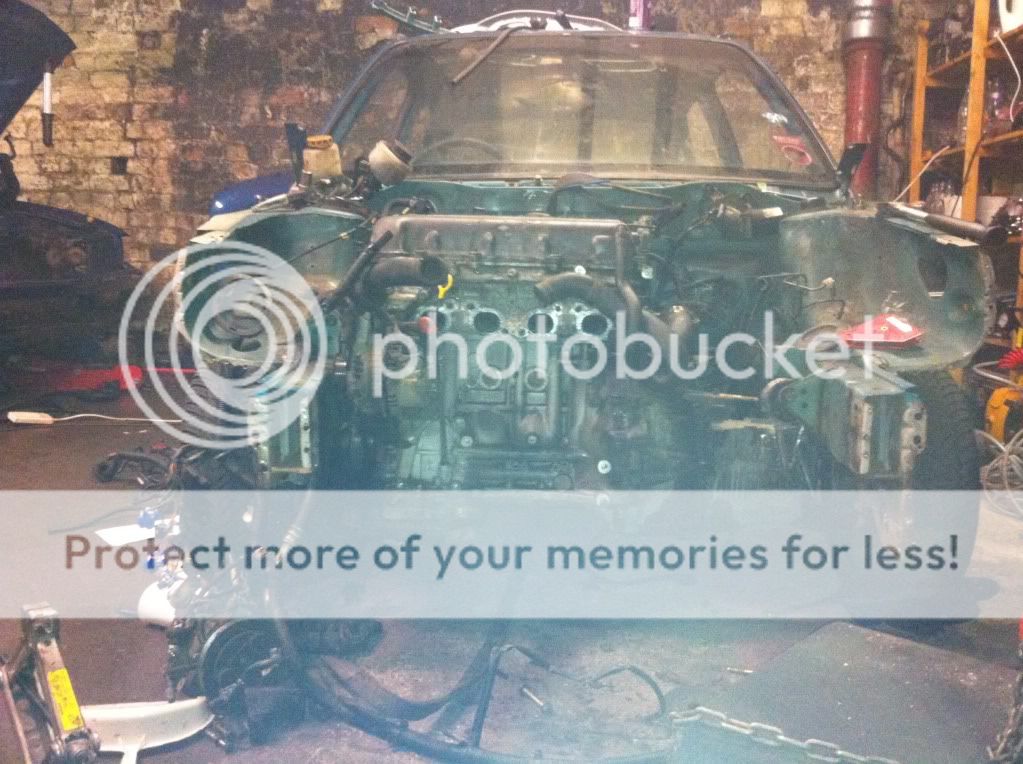

So tonight was mainly spent on De-rusting the Turtle.

Both Rear innner and outer arches need attention aswell as one of the chassis legs and under one of the wing mirrors.

So i set to work with the grinder and flap wheel on removing all the rust. I started on one of the rear arches which wasnt that bad. Just alot of surface rust. So with that grinded down I Put on some Hammerite rust remover gel.

And my paintbrush!

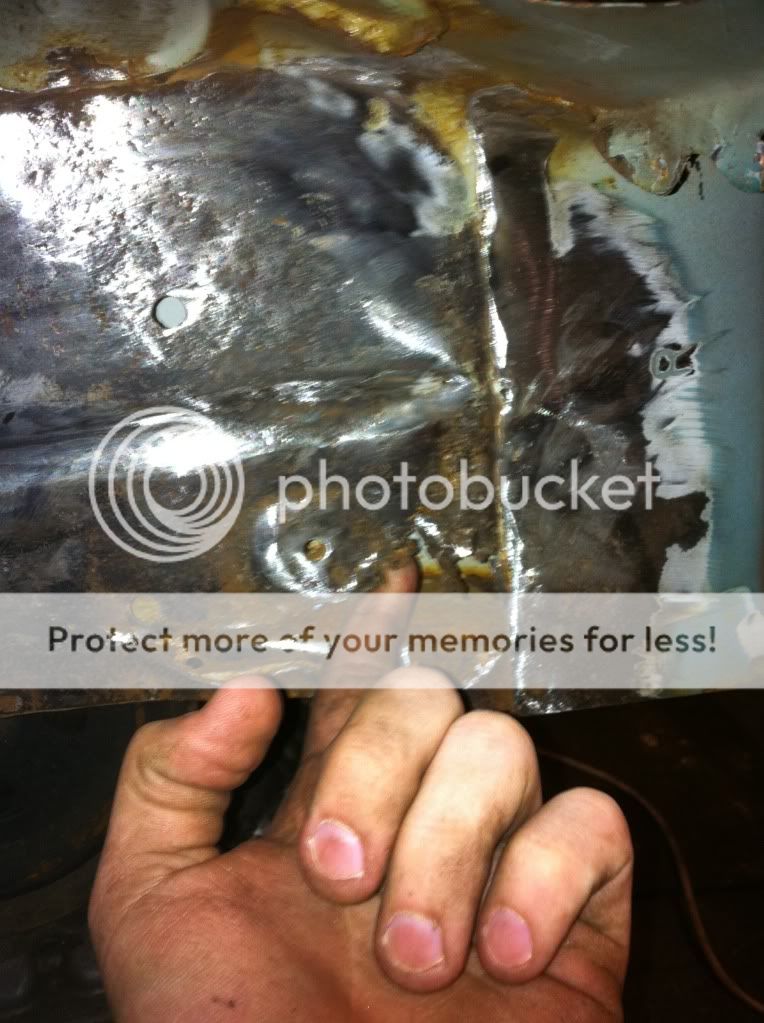

I then moved onto the front chassis leg which had a gaping hole. This needed welding... So grinder again to take back most of the rust for a plate to be welded over the whole.

Rusty hole with the metal resembling "biscuit". It was very thin.

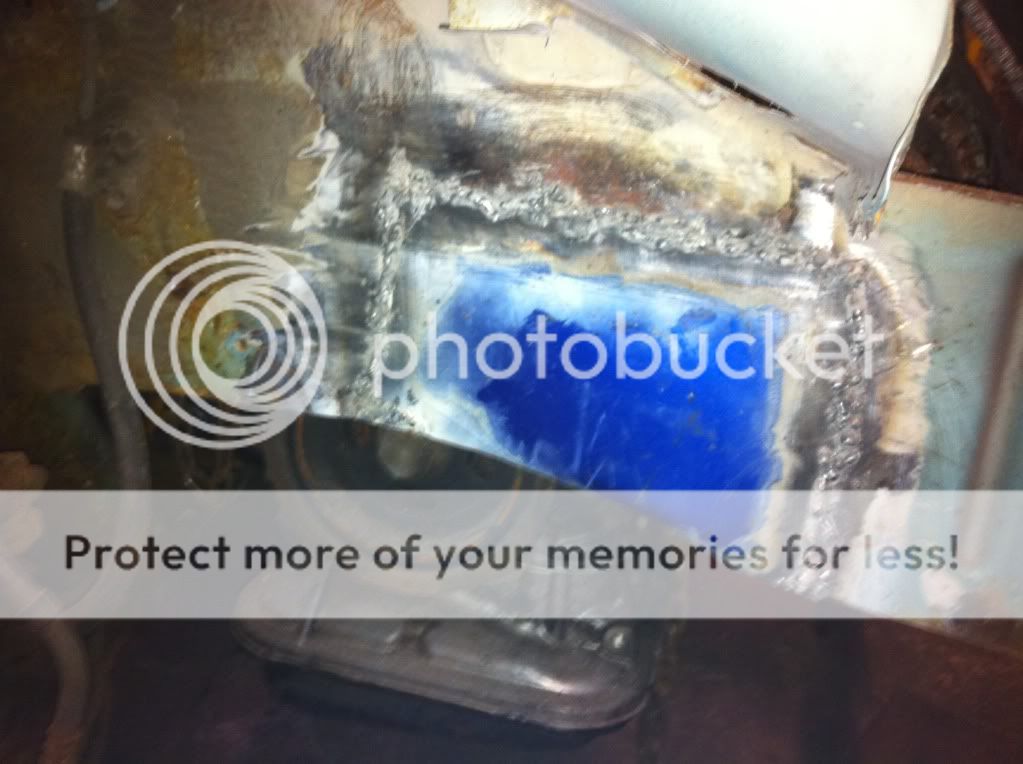

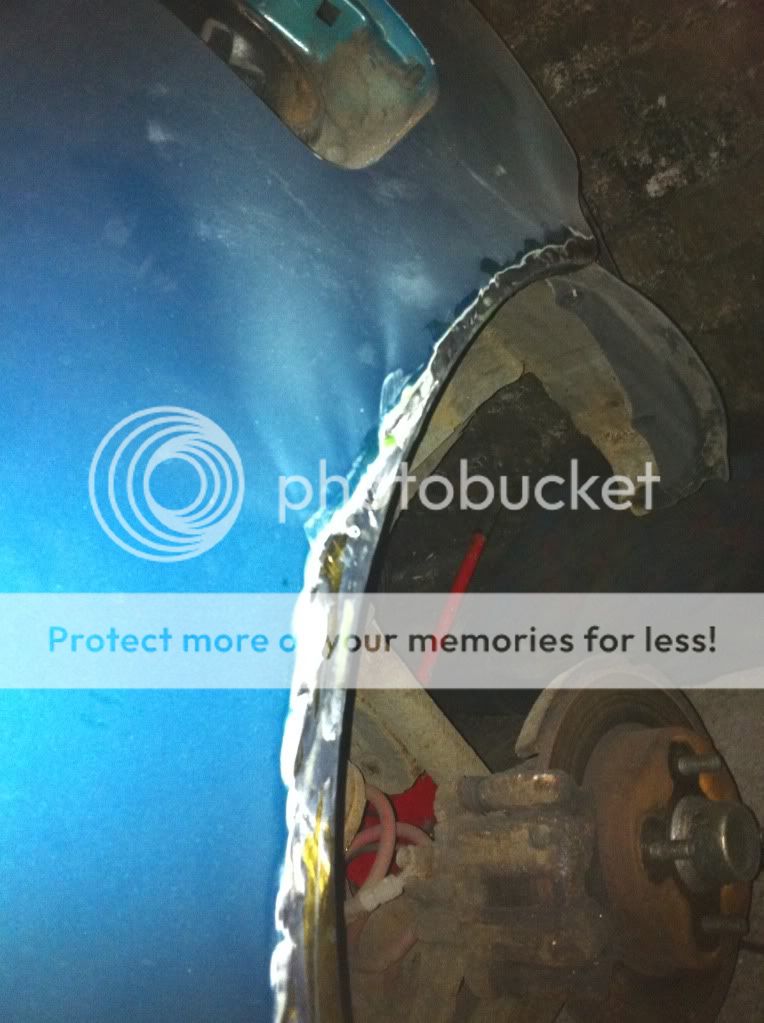

Once the Rust was grinded back, a template was made from the hole and a sheet of metal was cut from a spare wing we had lying around. Welder out and Ross welded the plate on. Yes the welder is sh*te

Theres still a bit left to do underneath, this will be done once the engine has been taken out again to have flywheel and clutch fitted.

Just needs to be brought round and welded up.

And some previous welding we done on the arch in the engine bay looking at it from inside the wheel arch. Not pretty but strong :

So with that done, more de-rusting on the door/wing mirror.

Rust grinded back, rust gel applied.

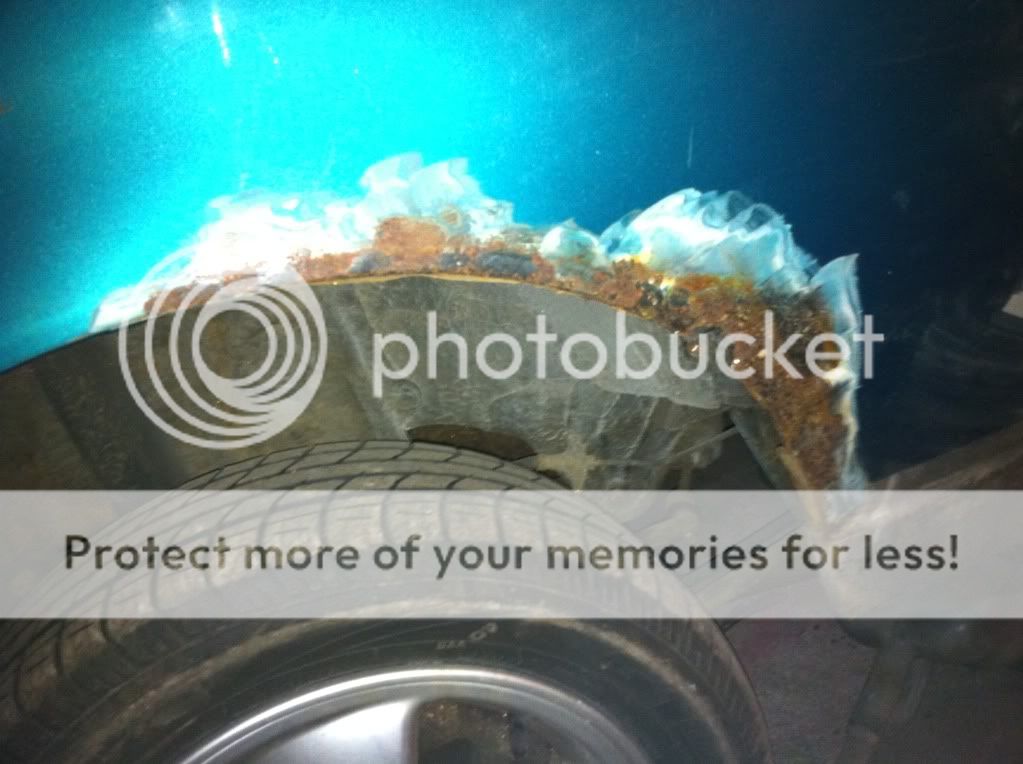

Then I moved onto the other rear arch... big mistake.

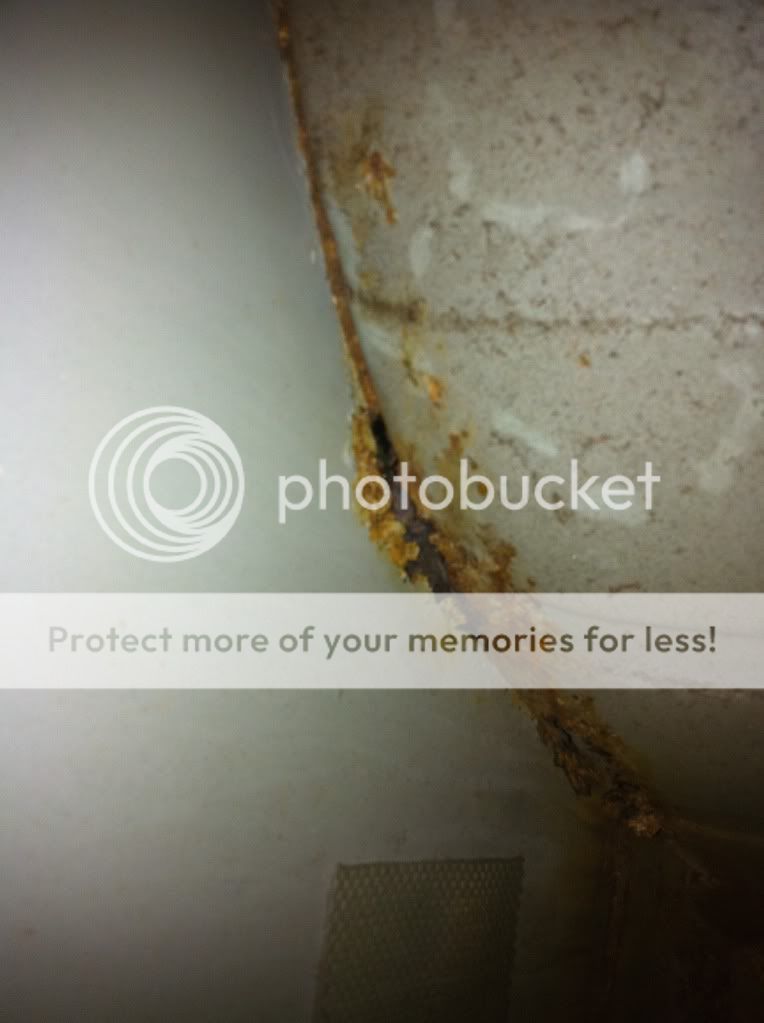

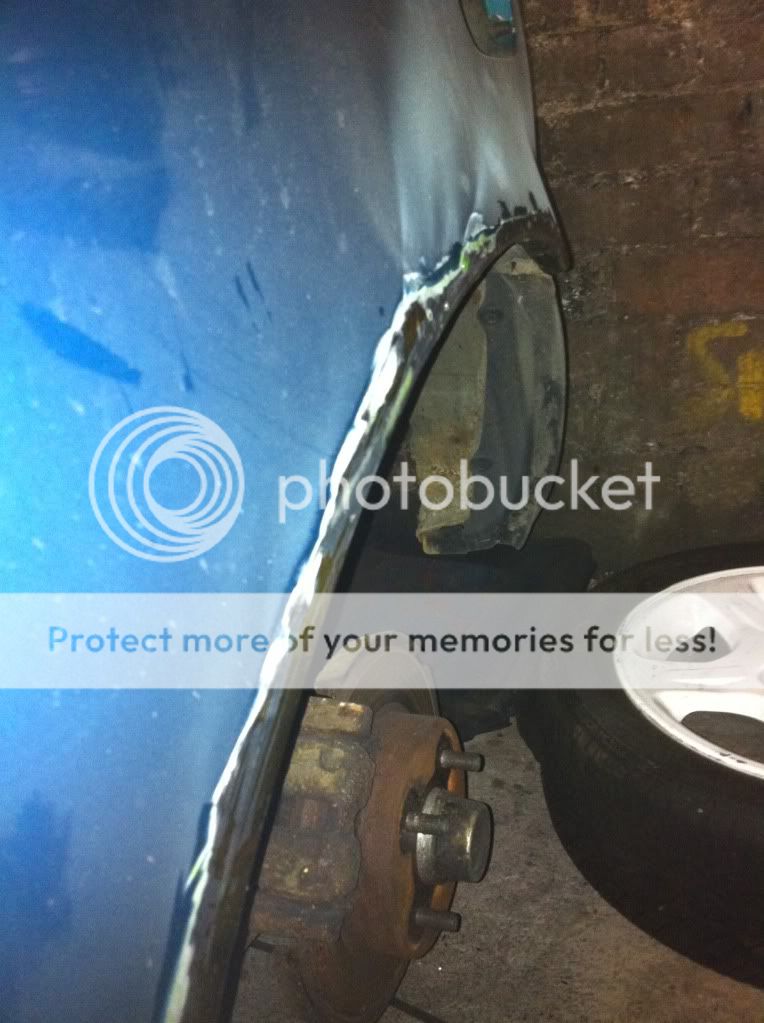

Surface rust grinded back along the arch and the arch lip. We knew that there would

be welding needed here but after a bit more inspection it was revealed that alot more was involved. First look showed a small gap into the inner arch. Ok cool a little bit of welding needed.

So after grinding back everything and poking the arch lip ( biscuit metal again) a larger hole was revealed (Thank you Rick...)

So now two plates will need to be welded in to try and regain as good a shape as possible to original.

More pics of rust and rust removal!

Thats all for the de-rusting just now. It feels good to kill the dreaded brown stuff.

All arches will be fillered up and sanded down then painted.

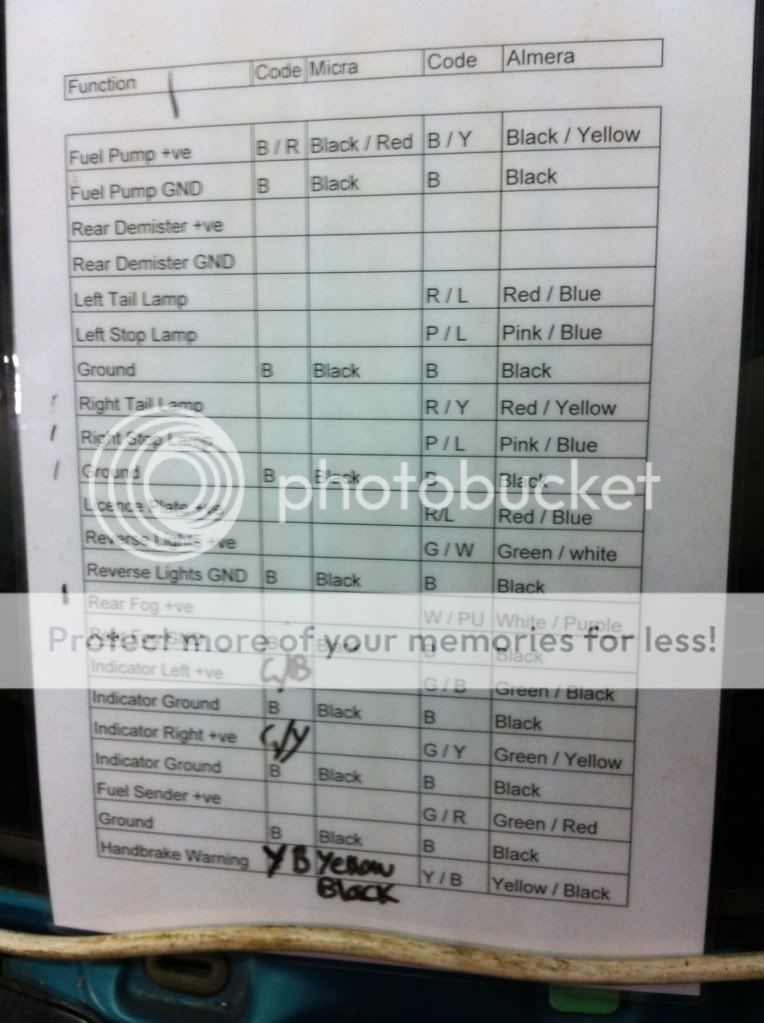

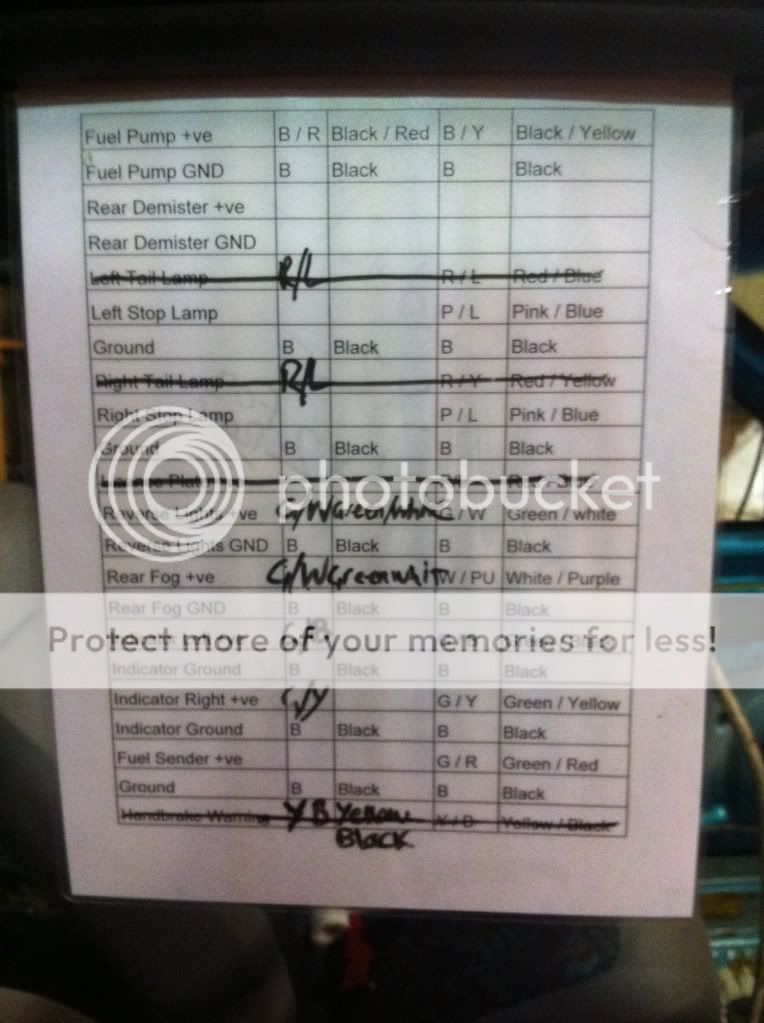

And on another note, all wiring is pretty much finished! Wires soldered up and heat shrinked. Just need to do the last few then it can all be tidied up.

Also another piece of the puzzle is solved. We have sourced the necessary NATS stuff (ECU, keychips and NATS IMMU box) to get the engine running. Thank you Joe!

So we are currently on track for the 27th April Deadline of getting the engine started. Just need to get the NATS stuff, remove the engine, fit the engine loom, fill with oils, mount back up and start it up!

(Y)