-

Please only use these forums for blogs, they are not a discussion forum

PollyMobiles Rebuild

- Thread starter pollyp

- Start date

not heard of them, tis new to me.

just looking at their product list, obviously a cg13de ain't on there and I have a different clutch,

but if someone has the answer to this Q, what nissan model was my 200mm helix organic clutch & PP originally intended for?

with the make & model, maybe it might already exist in their list, or I order a fidanza flywheel for that make model n I just bolt this clutch onto it?

u get a quote from TTV?

Bought mine straight from Matt H, 2.8kg.

That's odd they used to be listed on the site, they have the cg10 & cg13 on the shelf, wouldn't take much to sort out a bigger clutch. Is the 200mm not the 2.0 primera jobbie?

pollyp

Club Member

Bought mine straight from Matt H, 2.8kg.

That's odd they used to be listed on the site, they have the cg10 & cg13 on the shelf, wouldn't take much to sort out a bigger clutch. Is the 200mm not the 2.0 primera jobbie?

ooh just checked his listing and yep there's a lightweight 1-piece special flywheel for 184 or 200mm clutch for £288 plus postage

u got a pic on ur blog?

I better get saving

ooh just checked his listing and yep there's a lightweight 1-piece special flywheel for 184 or 200mm clutch for £288 plus postage

u got a pic on ur blog?

I better get saving

Don't forget the dredded VAT too mate!

Demontweeks stock TTV parts, might be worth trying some club discoubt there?

Attachments

pollyp

Club Member

Don't forget the dredded VAT too mate!

Demontweeks stock TTV parts, might be worth trying some club discoubt there?

oh gawd that VAT, thought his listing says including vat?

well at least I know the humphris route will definately fit the 200mm clutch (should phone him to check), but at a huge cost.

#holds onto screaming wallet, must.not.impulse.buy#

that TTV flywheel u got there looks very similar to my old JUN flywheel in terms of bolt holes & lightening holes so may not fit a 200mm clutch. u using 180 or 200mm clutch on it at the mo?

on my redrilled stock flywheel, the new holes r right near the outer edge of the starter ring

if I knew the make model & litre of the 200mm clutch then the racing flywheels in Demontweeks could be another option, same expense as humphris.

couldn't find listing for 2L primera but they list 300zx/350/NX/Sentra/Silvia/200sx/Skyline

pollyp

Club Member

Hmm here's a mad thought. What if I get my old JUN flywheel (that no one wants) machined with holes 10mm further out for the 200mm clutch and flattened n not care if afew mm of the clutch plate crosses the lightening holes? I mean 1/2 the current discs outer face has been worn more convex cos the flywheel wasn't machined flat so initially it won't conflict.

spending few quid machining my old £500 jun fly is prob a better option than another £300+ on a custom fly?

spending few quid machining my old £500 jun fly is prob a better option than another £300+ on a custom fly?

8kgs? It shouldn't be that much Chris.

No longer a consideration but FYI, those are for 184mm and 200mm Helix/Tilton Racing clutches. Which means the bolt pattern will be different and there will be a step machined into the flywheel for the cover plate to sit in.

Like the flywheel which was posted up on facebook a while back and no-one knew what it was...

ooh just checked his listing and yep there's a lightweight 1-piece special flywheel for 184 or 200mm clutch for £288 plus postage

u got a pic on ur blog?

I better get saving

No longer a consideration but FYI, those are for 184mm and 200mm Helix/Tilton Racing clutches. Which means the bolt pattern will be different and there will be a step machined into the flywheel for the cover plate to sit in.

Like the flywheel which was posted up on facebook a while back and no-one knew what it was...

SirChris

Educated Bodger

I was taking the piss lol if I remember correctly it 6. Something.8kgs? It shouldn't be that much Chris.

No longer a consideration but FYI, those are for 184mm and 200mm Helix/Tilton Racing clutches. Which means the bolt pattern will be different and there will be a step machined into the flywheel for the cover plate to sit in.

Like the flywheel which was posted up on facebook a while back and no-one knew what it was...

Trying to understand this statement more,..talking to andy at santapod bout my thoughts of lightening a 1-piece 1.3 flywheel for the 200mm clutch on my turbo setup, he says not a good idea due to it's brittleness n heat cycle cracking after removing material, especially in my application of 160ftlb being used as a daily with occasional long trackdays at max rpm.

From what I've seen of the lightened one piece flywheels on here and my own (which I'm planning to lighten) you are taking off the extra material from the outside that Nissan added for more inertia ? You don't actually make it thinner than it is already at its thinnest part, so therefore not making it weaker (or at least in my head) so then why is it not recommended in this case? Is it because the extra duty required by the turbo etc means more heat etc dumped into a smaller mass which isn't a problem in n/a applications? Or is there something wrong with lightening the one piece flywheel?

h701micra

Deactivated Account

As am ITrying to understand this statement more,..

Ps don't get your Andys mixed up folk... I wasn't there

pollyp

Club Member

As am I

Ps don't get your Andys mixed up folk... I wasn't there

Lol I shall call u Mr H701 now on

pollyp

Club Member

As am I

Ps don't get your Andys mixed up folk... I wasn't there

Lol I shall call u Mr H701 now on

pollyp

Club Member

Trying to understand this statement more,..

From what I've seen of the lightened one piece flywheels on here and my own (which I'm planning to lighten) you are taking off the extra material from the outside that Nissan added for more inertia ? You don't actually make it thinner than it is already at its thinnest part, so therefore not making it weaker (or at least in my head) so then why is it not recommended in this case? Is it because the extra duty required by the turbo etc means more heat etc dumped into a smaller mass which isn't a problem in n/a applications? Or is there something wrong with lightening the one piece flywheel?

Enuo mentioned bout how cast iron expands n contracts lot more than steel/alu so dumping a huge amount of heat energy from the high torque of the turbo on multiple trackdays onto a flywheel with less material & heat latency than original "could" create heat stress cracks, like on brakes, till it eventually fails at high rpm.

But I ain't a mech engineer to verify

pollyp

Club Member

8kgs? It shouldn't be that much Chris.

No longer a consideration but FYI, those are for 184mm and 200mm Helix/Tilton Racing clutches. Which means the bolt pattern will be different and there will be a step machined into the flywheel for the cover plate to sit in.

Like the flywheel which was posted up on facebook a while back and no-one knew what it was...

But for sure that flywheel on Humphris list will support the 200mm clutch that's from the same list?

U mean the bolt pattern of the helix racing pp is different to a standard 200mm flywheel?

pollyp

Club Member

I think once I removed the gearbox n flywheel to investigate the oil leak, I'll take my old steel 3.4kg JUN flywheel to a machinist to flatten & redrill bolt holes for the 200mm PP. Dunno if I should go back to usual local place in next town n get ripped off or try another more local machinist (imo should try another one).

So guess there's no trackdays for me till near end June.

So guess there's no trackdays for me till near end June.

pollyp

Club Member

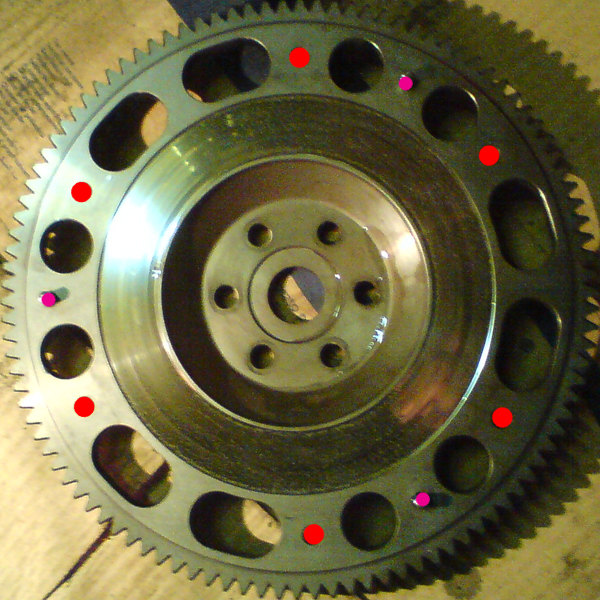

comparing the pcd of the stock PP vs 200mm PP.

here's the standard 180mm PP bolt holes & clutch plate marks on the old JUN flywheel

and here's the 200mm PP & disc

now carefully overlapping the two together, we can see there's just enough steel for the 200mm PP bolt holes and the 200mm clutch disc will overhang the void holes by about 5mm but shouldn't be a problem. the light blue locating pins (three this time rather than a flimsy one) will obviously need relocating inbetween the bolt holes

here's the standard 180mm PP bolt holes & clutch plate marks on the old JUN flywheel

and here's the 200mm PP & disc

now carefully overlapping the two together, we can see there's just enough steel for the 200mm PP bolt holes and the 200mm clutch disc will overhang the void holes by about 5mm but shouldn't be a problem. the light blue locating pins (three this time rather than a flimsy one) will obviously need relocating inbetween the bolt holes

pollyp

Club Member

The bolt holes on a 200mm Helix racing clutch sit on a 214mm PCD, 6-bolt M8.

thx low rider, I'll go measure the jun flywheel in garage to double check the holes fit

pollyp

Club Member

rear axle now moved forward & no longer bangs the exhaust, wheels all aligned straight and front camber equalised at -1.75deg

still drifts abit left due to unequal tread depths but at least they're all pointing ahead.

the new SS inlet pipe definately needs insulating & heat shielding from the hot infra radiation off the manifold.

H701 has the rear dampers arrived yet?

since you need more time spending on paid projects and I need a manifold for anymore trackdays soon, perhaps I should attempt to finish off the manifold myself here?

still drifts abit left due to unequal tread depths but at least they're all pointing ahead.

the new SS inlet pipe definately needs insulating & heat shielding from the hot infra radiation off the manifold.

H701 has the rear dampers arrived yet?

since you need more time spending on paid projects and I need a manifold for anymore trackdays soon, perhaps I should attempt to finish off the manifold myself here?

pollyp

Club Member

Should always drift left for natural road camber

No dampers only springs arrived. I still need that PayPal thing doing too

You could do if you wished

think it's unequal tread depths that always influences the pull cos whenever I realigned the wheels with new thick tyres she cruises straight.

any idea when it'll arrive or there must be some sorta tracking number?

paypal for the dampers, pm me how much and what's ur paypal email?

how far u got with the mani? managed to get flange cut? brought any bends? just hope my arc weld skills can deal with the thin tubes n not blow holes

once the rear dampers arrive, then I'll pop round to swap em & see what to do bout manifold cos tis a long journey

h701micra

Deactivated Account

Cruising straight on cambered roads is a sign of incorrect tracking chapthink it's unequal tread depths that always influences the pull cos whenever I realigned the wheels with new thick tyres she cruises straight.

any idea when it'll arrive or there must be some sorta tracking number?

paypal for the dampers, pm me how much and what's ur paypal email?

how far u got with the mani? managed to get flange cut? brought any bends? just hope my arc weld skills can deal with the thin tubes n not blow holes

once the rear dampers arrive, then I'll pop round to swap em & see what to do bout manifold cos tis a long journey

I don't get tracking numbers I just get update emails

I need to arrange flange cutting but bends are simple. But I may have a rethink regarding restriction removal

pollyp

Club Member

Slightly off topic but i am fairly new to the forum so am still filtering through build threads and this has been the best i have read to date. So good in fact i have sat up until 1:30am without realising it. What an amazing build. Any problems im calling you mate@pollyp

Glad u enjoy a good read, time flys when u enjoy sumthing eh

A lot of info in here, I'll try point ya in right direction.

pollyp

Club Member

It'll be 10mm no less. Warp free that way

Having the tooling and time to accurately cut out the flange is difficult

Laser cutting would be much more efficient

Sweet. Well the exh flange models of various port sizes r in dropbox. Once dampers n flange r ready lemme know asap

Thanks @polyp I'm really trying to learn the parts and such of the engine as I'm only 17 and my k11 is my first car! Hopefully I can come to a meet soon and someone can check it over ahaha just kidding  thanks a lot I'm gonna read more later only on page 7 or so!:laugh:

thanks a lot I'm gonna read more later only on page 7 or so!:laugh:

Sent from my iPhone using Tapatalk

Sent from my iPhone using Tapatalk

pollyp

Club Member

Thanks @polyp I'm really trying to learn the parts and such of the engine as I'm only 17 and my k11 is my first car! Hopefully I can come to a meet soon and someone can check it over ahaha just kiddingthanks a lot I'm gonna read more later only on page 7 or so!:laugh:

Sent from my iPhone using Tapatalk

we've all gotta start somewhere to build our skills & experiences.

I started building my basic mechanics skills 101 & habits since childhood by tinkering & fixing bicycles & all sorts.

when I got my first car, had basic tools and got haynes manual, which is essential, then just learn by doing, research and ask Q in forum when stuck.

yeah need to get myself a haynes manual, just keep using that search bar in stead of asking when i can.. currently treating my wheel arch for rust (i dont know if you seen)

but yeah, thats a fun job :laugh:

dont mean to hijack but any tips?

but yeah, thats a fun job :laugh:

dont mean to hijack but any tips?

yeah need to get myself a haynes manual, just keep using that search bar in stead of asking when i can.. currently treating my wheel arch for rust (i dont know if you seen)

but yeah, thats a fun job :laugh:

dont mean to hijack but any tips?

Sand, till bare (or near to bare) metal then use rust killer. Sand then degrease and use Etch primer, then colour layer. Sand between primer and colour layer with 1k wet paper

wonderful cheers

pollyp

Club Member

yeah need to get myself a haynes manual, just keep using that search bar in stead of asking when i can.. currently treating my wheel arch for rust (i dont know if you seen)

but yeah, thats a fun job :laugh:

dont mean to hijack but any tips?

good lad, there's also an index page on the 1st post to summerise most stuff.

for surface rust I try to remove as much rust off till it's only bare metal (wirebrush drill, angle grind, rough sanding), rust treat, optional filler & sand smooth, roughen whole panel with scotchpad, primer, base coat, laquer, tcut then polish.

alright thanks ill try my best, now get back to talking about what you were talking about!

Thanksss

Thanksss

pollyp

Club Member

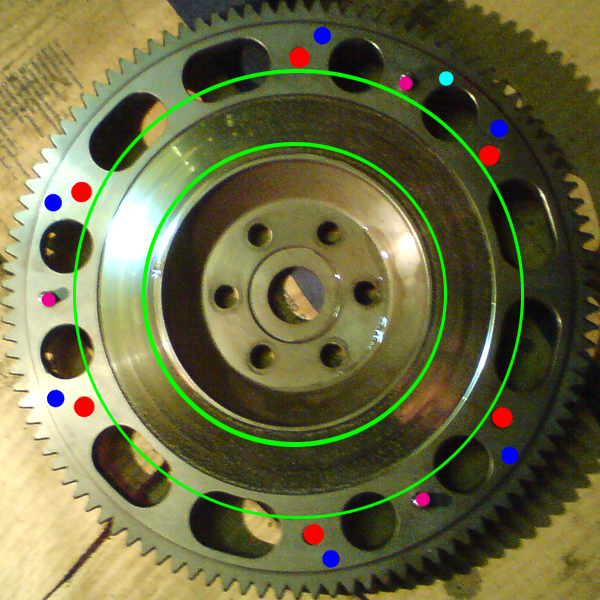

brought a euro travel kit for the trip to germany

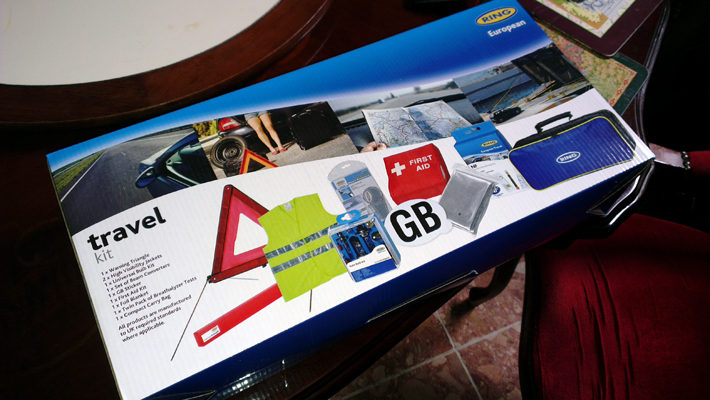

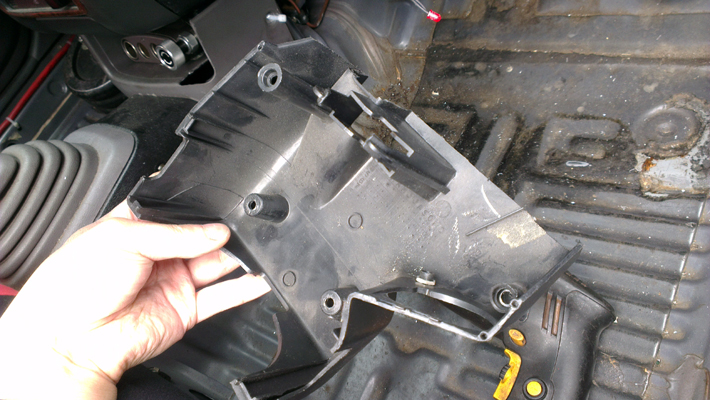

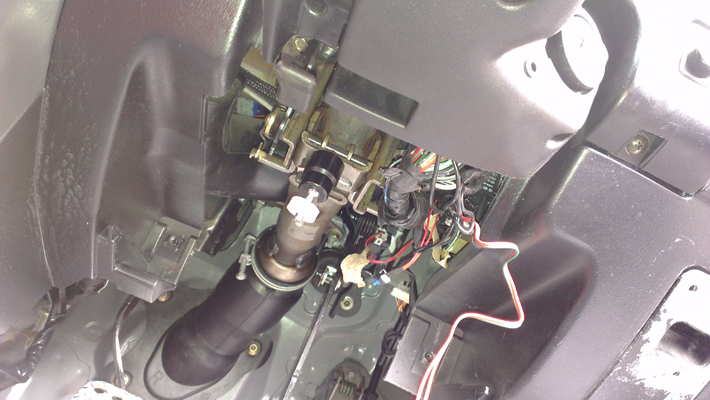

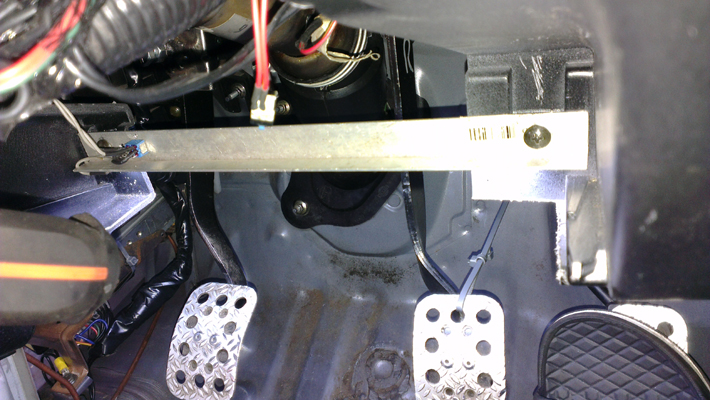

to secure the pedal cam in a better and stiffer point, I drilled & screwed the ball mount under the steering column

trimmed the plastic cover to clear it

and now it sits firmly, directly over the pedals and out the way

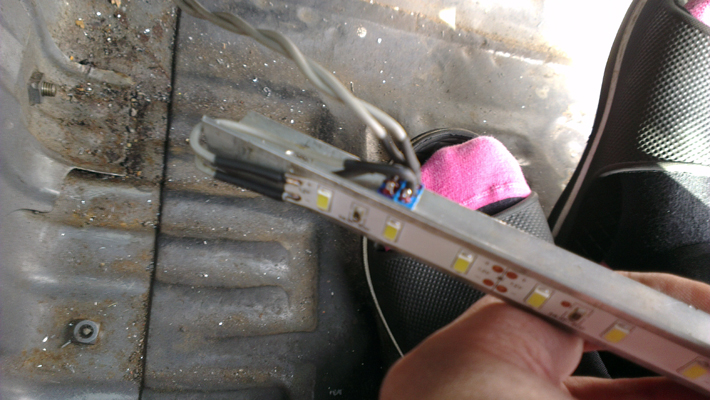

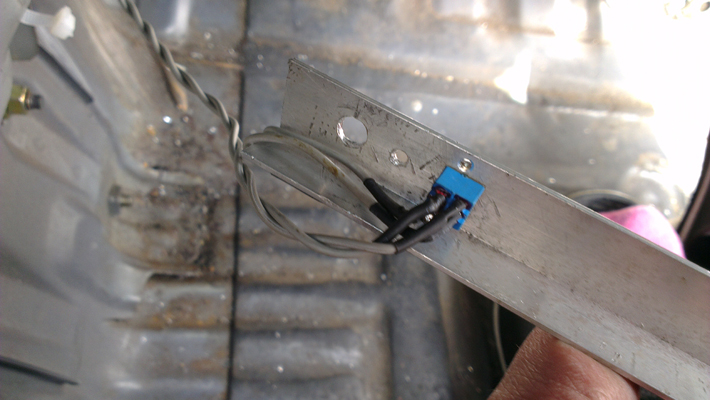

to replace the bulky flashlight with the LED strip, I stuck the strip onto a length of Alu L bar

soldered the wiring to a toggle switch

and tapped into the 12v cig lighter feed

screwed in place and yay it lights the pedal bay better and out the way

to secure the pedal cam in a better and stiffer point, I drilled & screwed the ball mount under the steering column

trimmed the plastic cover to clear it

and now it sits firmly, directly over the pedals and out the way

to replace the bulky flashlight with the LED strip, I stuck the strip onto a length of Alu L bar

soldered the wiring to a toggle switch

and tapped into the 12v cig lighter feed

screwed in place and yay it lights the pedal bay better and out the way

pollyp

Club Member

Dismantling a reclining sports seat

lets open up & see if this worn seat can be fixed.

two bolts attach the upright & tilt mechanism to the seat base frame

separated

these clips holding the fabric covers together easily bend open

the loose undercover comes off

now the base cover can slip off

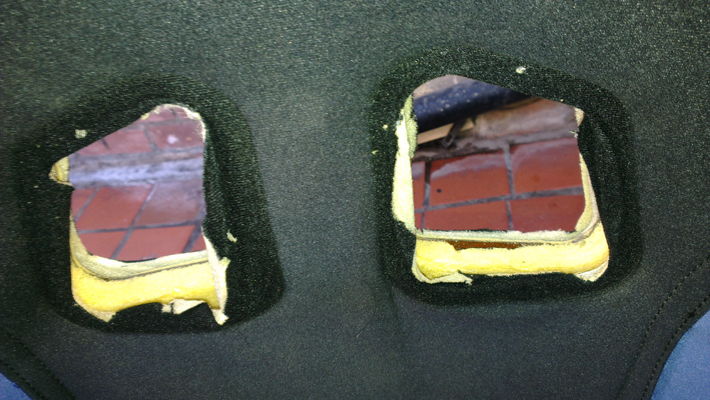

eek look at how ruined the foam is down to the steel tubular frame

the fabric cover is kept snug tight onto the foam via series of rods & tension wires, very similar to a tent

removing the tensioning loops, the cover is removed from the foam base

rods going through the covers like tent poles

here's a nasty dissitegrated foam seat. due to how much foam is worn and that it's literally built around the metal frame, can say there's zero point in trying to rebuild it when they're just £40 each.

so in the name of research for you ppl, lets rip it apart & see what the structure is actually like underneath

here's the bare chassis, not alot to it and not exactly structurally strong tbh in case of impact

the shoulder frame welded to the base

the rail mounting points roughly welded to the base frame

the side flange arc welded to the base rail, the weld slag is still there

this front bit of the frame simply kinked upwards

seat base springs

this rear support bracket simply tacked on at a single point :/

pivoting bracket welded good onto the side

so this is where we sit on

lets open up & see if this worn seat can be fixed.

two bolts attach the upright & tilt mechanism to the seat base frame

separated

these clips holding the fabric covers together easily bend open

the loose undercover comes off

now the base cover can slip off

eek look at how ruined the foam is down to the steel tubular frame

the fabric cover is kept snug tight onto the foam via series of rods & tension wires, very similar to a tent

removing the tensioning loops, the cover is removed from the foam base

rods going through the covers like tent poles

here's a nasty dissitegrated foam seat. due to how much foam is worn and that it's literally built around the metal frame, can say there's zero point in trying to rebuild it when they're just £40 each.

so in the name of research for you ppl, lets rip it apart & see what the structure is actually like underneath

here's the bare chassis, not alot to it and not exactly structurally strong tbh in case of impact

the shoulder frame welded to the base

the rail mounting points roughly welded to the base frame

the side flange arc welded to the base rail, the weld slag is still there

this front bit of the frame simply kinked upwards

seat base springs

this rear support bracket simply tacked on at a single point :/

pivoting bracket welded good onto the side

so this is where we sit on

pollyp

Club Member

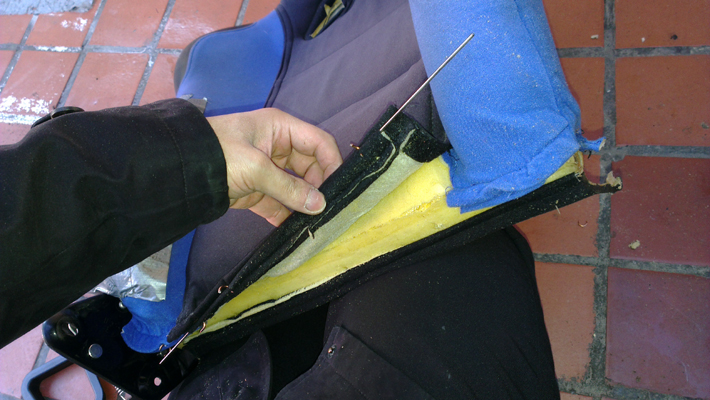

unclip the upright covers

these plastic harness holes are glued together so will break when trying to remove em

unhooked the lower support rod from the shoulder covers

the middle seat covers velcro'd to the shoulders with some support rods

the shoulder covers are anchored to the frame with more clips

unclipped and can now slip the covers off

again the foam is built arount the hollow metal frame

ffew straps across the seat back and the harness holes are the only panelled section

it looks like a jammy dodger now lol

ok one ruined seat going to the bins.

but with this info I can now possibly dismantle the red seat base and trim some excess foam away so the square edge doesn't dig into my thighs

these plastic harness holes are glued together so will break when trying to remove em

unhooked the lower support rod from the shoulder covers

the middle seat covers velcro'd to the shoulders with some support rods

the shoulder covers are anchored to the frame with more clips

unclipped and can now slip the covers off

again the foam is built arount the hollow metal frame

ffew straps across the seat back and the harness holes are the only panelled section

it looks like a jammy dodger now lol

ok one ruined seat going to the bins.

but with this info I can now possibly dismantle the red seat base and trim some excess foam away so the square edge doesn't dig into my thighs

pollyp

Club Member

That metal bar you screwed in for your lighting of pedals, looks a bit sketchy in regards to destroying your shins in the event of a crash/spin...

Certainly lead to some bruising at least :/

naa the legs don't normally reach that high n deep and it's just a thin strip of Alu screwed onto a plastic section of the dash.

the only way my feet would bash this bar is if tumbling upside down, and at that point hitting my ankles on a weak strip of alu is the very least of my worrys in comparison to the knees striking the dash first, pedals shooting inwards, the roof caving or the doors buckling in

K11 ain't exactly safe going at speed and tbh if there's a smash it's gonna hurt

naa the legs don't normally reach that high n deep and it's just a thin strip of Alu screwed onto a plastic section of the dash.

the only way my feet would bash this bar is if tumbling upside down, and at that point hitting my ankles on a weak strip of alu is the very least of my worrys in comparison to the knees striking the dash first, pedals shooting inwards, the roof caving or the doors buckling in

K11 ain't exactly safe going at speed and tbh if there's a smash it's gonna hurt

Tis a fair point haha

pollyp

Club Member

I know I have asked before but... what camera(s) do you use for the pedals etc... i like the fact yours has a proper tripod screw mount.

Drift X170 action cam, has 170deg rotating lens, 2 AA batt, SD card and remote controlled.

using these mini ball joint cam mounts off ebay.

pollyp

Club Member

k stored the seat frame in the garage cos maybe one day in future I may reweld it into a solid static bucket seat and then mould my own custom foam base with 2 part PU.

cleaning & repainting these peeling track wheels, I wirebrush the peeling old paint off

wirebrushed the tatty insides

smoothing the whole surfaces with emery cloth is soo labour intensive, I only have enough stamina for 1 wheel a day :/

masked the edges

wrapped the tyre like a fish supper

primered

cleaning & repainting these peeling track wheels, I wirebrush the peeling old paint off

wirebrushed the tatty insides

smoothing the whole surfaces with emery cloth is soo labour intensive, I only have enough stamina for 1 wheel a day :/

masked the edges

wrapped the tyre like a fish supper

primered

pollyp

Club Member

sanded the other peeling wheel, gawd my fingers r aching dry & numb from sanding every nook cranny :/

masked

primered & painted matt black

once dry looks like this Mmm

highlighted the tyre names

looks very nascar like.

just painting the front peeling wheels enough work for now, gonna leave the rears white till I find enough motive for it

insulated the inlet pipe and it stays cool now

masked

primered & painted matt black

once dry looks like this Mmm

highlighted the tyre names

looks very nascar like.

just painting the front peeling wheels enough work for now, gonna leave the rears white till I find enough motive for it

insulated the inlet pipe and it stays cool now

pollyp

Club Member

with the old drivers seat ruined, I have a spare seat rail and this would be the best time to resolve the high seat position by remodifying a new seat rail to sit much lower.

assessing the seat rail during the hot day I figure that the seat could be mounted a massive 20-30mm lower

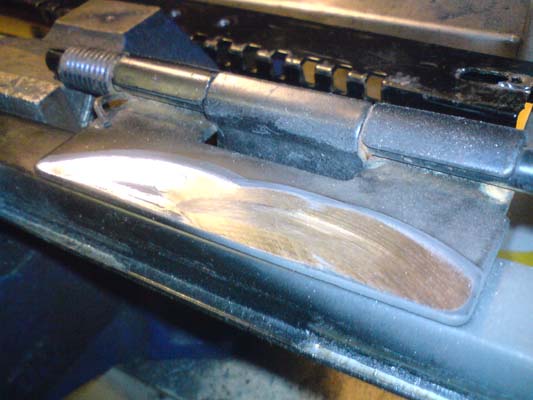

so here's the standard seat rail that came with the reclining sports seat

the rails r limited by some dimples so I cut & drilled them out

and the rails slide apart to reveal the rollers & ball bearings

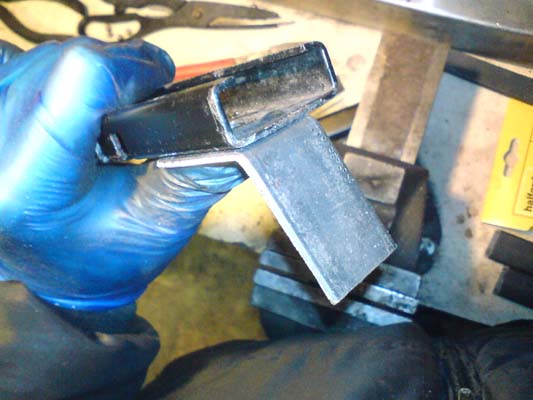

this latch handle hinge curls upwards towards the seat base so would have to use a 5mm spacer to provide clearance. to eliminate the spacer, I'll have to flip the hinge

grinded the rivets off

flipped & welded the bracket to the rail (didn't have any 6mm pop rivets for the hole)

in order to disassemble & reverse the handle rod, had to cut the latch teeth off then slide the rod out to flip

with the flipped rod handle closer to the ridges, had to trim & bend the teeth section

reassemble the sprung rod handle & welded the teeth section on

reassembled the bearing sliders & locked it all together with pop rivets in place of the previous dimples/stoppers

some brackets & rear legs will be welded onto the rails tomorrow

assessing the seat rail during the hot day I figure that the seat could be mounted a massive 20-30mm lower

so here's the standard seat rail that came with the reclining sports seat

the rails r limited by some dimples so I cut & drilled them out

and the rails slide apart to reveal the rollers & ball bearings

this latch handle hinge curls upwards towards the seat base so would have to use a 5mm spacer to provide clearance. to eliminate the spacer, I'll have to flip the hinge

grinded the rivets off

flipped & welded the bracket to the rail (didn't have any 6mm pop rivets for the hole)

in order to disassemble & reverse the handle rod, had to cut the latch teeth off then slide the rod out to flip

with the flipped rod handle closer to the ridges, had to trim & bend the teeth section

reassemble the sprung rod handle & welded the teeth section on

reassembled the bearing sliders & locked it all together with pop rivets in place of the previous dimples/stoppers

some brackets & rear legs will be welded onto the rails tomorrow

pollyp

Club Member

welded the rear support

diagonal cut the lower leg for accessing the bolt

knew it was a good idea to keep that old seat frame cos I can now use it as a jig to secure the rails straight & parallel to the actual seat layout

bolted the front mount brackets to the chassis

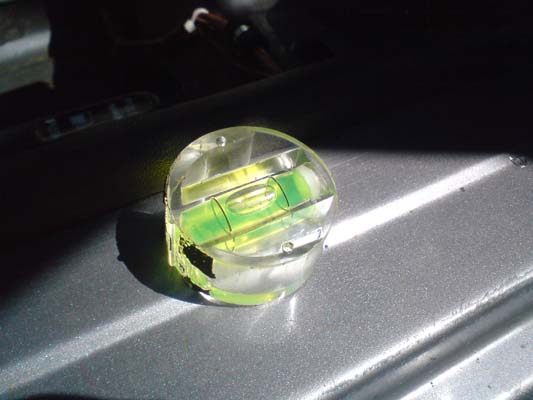

to ensure the seat rail is sliding parallel with the floor I first level the sills as point of reference

rest a straight edge on the front mount till it also reads level, measure the gap from floor mount to the straight edge & adjust the rear mount to that length

trimmed the washers to fit the bolt inside the square tube sections

now resting the seat rails on the 3 mounts,

make the 4th mount later on,

using the heavy toolbox to hold the frame down,

aligning the rails at an equal distance from the sill (this led to an issue later on)

tacked on place

welded

now making this inner rear mount was a pain, took few hours of trimming to get this compound angle joint right :/

some complex angle

tacked

welded. seems getting a good solid electrical ground makes a big difference in how well the welder works, tis such a pleasure when a slight tweak of technique (a nonstop zigzag pass, but only at solid joins) makes a luvely smooth filleted weld near the open edges of the metal was obviously a little trickier to control heat but just used a pulse technique to keep heat down

near the open edges of the metal was obviously a little trickier to control heat but just used a pulse technique to keep heat down

check final fit

fit the new rails on the red seats

and installed. comparing the seat base height from the sunroof, the drivers seat is now 25mm lower

but now I noticed that aligning the rails parallel to the sills meant that the wide upper shoulders of the seat is resting snug against the seat belt

the old rails were actually pointing slightly right so the rear side was further away from the b-pillar, which I should've noticed & took advantage of :/

well I can't make another one so an easy quick fix is to lift the rear right mount up with spacers to tilt/twist the seat backing inwards to clear the seat belt and it worked

so went for a test drive and there's more head room so won't hit the sunroof with my helmet.

by lowering the seat height, although it may seem a tiny amount, it's altered the leg/foot angle so the pedals felt alot different.

when I slide the seat to my usual point the clutch & brake felt abit too close so had to slide it back by 2-3cm to feel right.

definately not touching the passenger rail cos really cba with all that effort and dad's abit shorter anyway so he's fine

well that'll be a spare bucket seat/k11 seat rail for the buy&sell

diagonal cut the lower leg for accessing the bolt

knew it was a good idea to keep that old seat frame cos I can now use it as a jig to secure the rails straight & parallel to the actual seat layout

bolted the front mount brackets to the chassis

to ensure the seat rail is sliding parallel with the floor I first level the sills as point of reference

rest a straight edge on the front mount till it also reads level, measure the gap from floor mount to the straight edge & adjust the rear mount to that length

trimmed the washers to fit the bolt inside the square tube sections

now resting the seat rails on the 3 mounts,

make the 4th mount later on,

using the heavy toolbox to hold the frame down,

aligning the rails at an equal distance from the sill (this led to an issue later on)

tacked on place

welded

now making this inner rear mount was a pain, took few hours of trimming to get this compound angle joint right :/

some complex angle

tacked

welded. seems getting a good solid electrical ground makes a big difference in how well the welder works, tis such a pleasure when a slight tweak of technique (a nonstop zigzag pass, but only at solid joins) makes a luvely smooth filleted weld

check final fit

fit the new rails on the red seats

and installed. comparing the seat base height from the sunroof, the drivers seat is now 25mm lower

but now I noticed that aligning the rails parallel to the sills meant that the wide upper shoulders of the seat is resting snug against the seat belt

the old rails were actually pointing slightly right so the rear side was further away from the b-pillar, which I should've noticed & took advantage of :/

well I can't make another one so an easy quick fix is to lift the rear right mount up with spacers to tilt/twist the seat backing inwards to clear the seat belt and it worked

so went for a test drive and there's more head room so won't hit the sunroof with my helmet.

by lowering the seat height, although it may seem a tiny amount, it's altered the leg/foot angle so the pedals felt alot different.

when I slide the seat to my usual point the clutch & brake felt abit too close so had to slide it back by 2-3cm to feel right.

definately not touching the passenger rail cos really cba with all that effort and dad's abit shorter anyway so he's fine

well that'll be a spare bucket seat/k11 seat rail for the buy&sell

Similar threads

- Replies

- 2

- Views

- 1K

- Replies

- 0

- Views

- 903