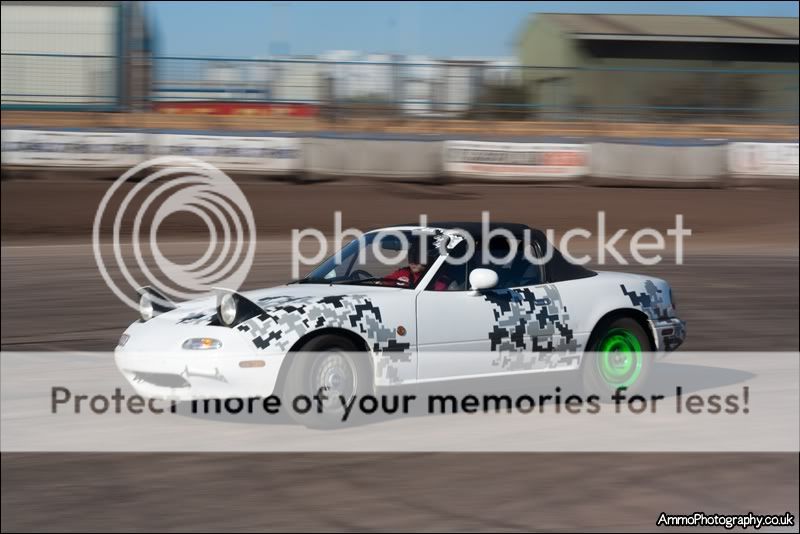

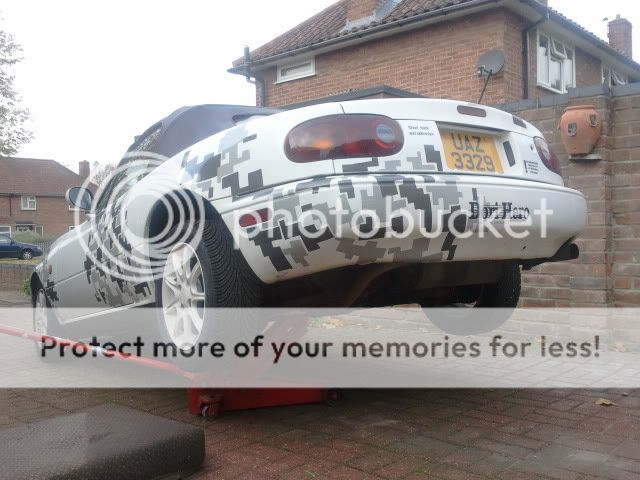

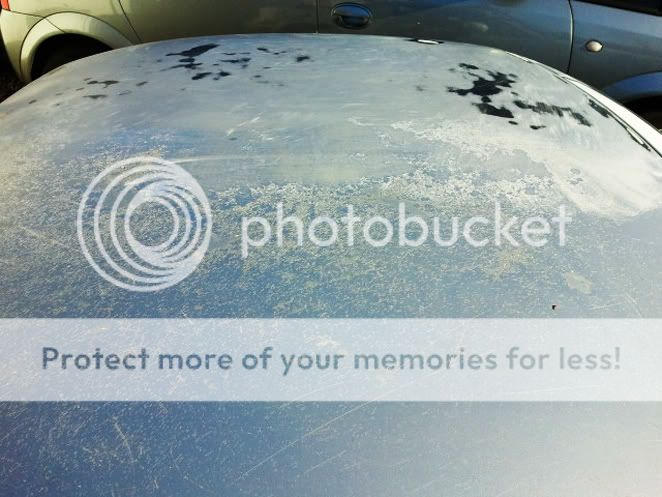

Met up with a mate yesterday to start work with the diff removal. Was quite suprised how high the jack went...

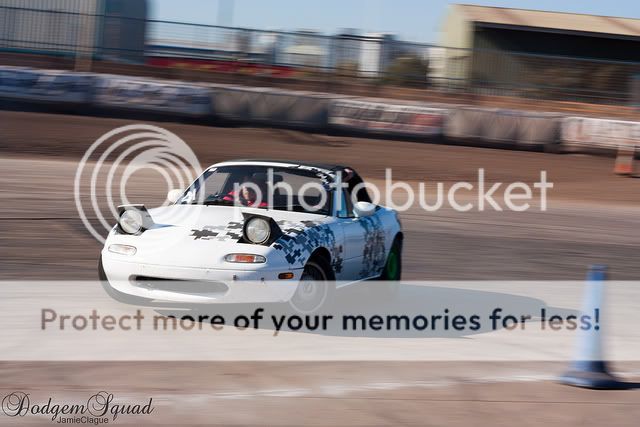

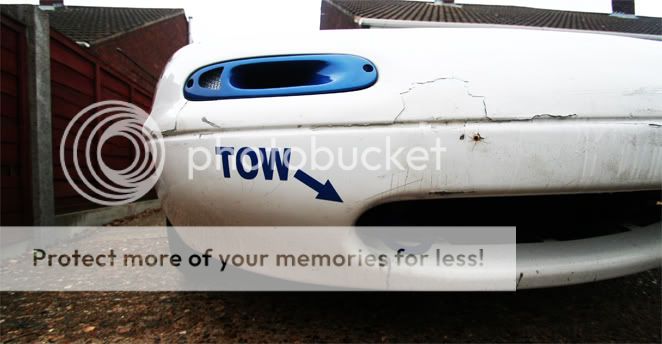

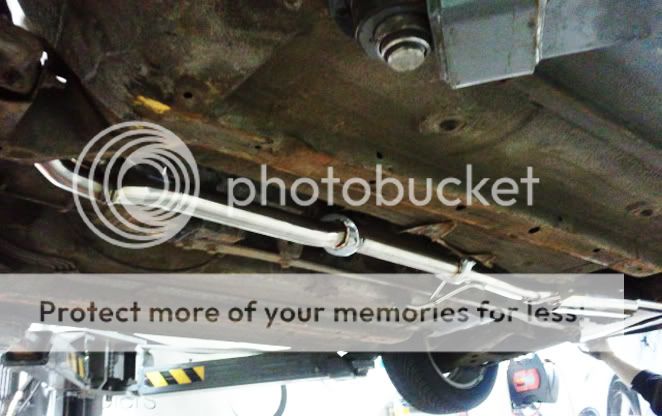

Once on axle stands we doused all the bolts/nuts with penitration oil,with the help of an impact gun the drive shafts and prop shaft was removed. Last thing to do was to remove the brace which goes between the gearbox and diff,one of the bolts was stuck and wouldnt come out.

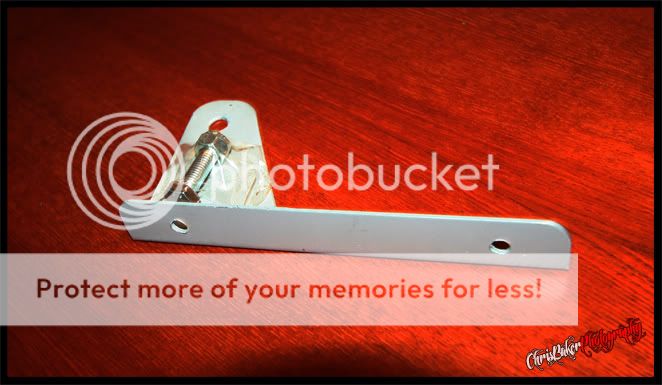

Abit of jiggling about and the help of more WD40 and a blow torch,the bolt finally came out. Now came the fun part and that was to strip the diff down. Heres the majority of the diff stripped down and all cleaned up

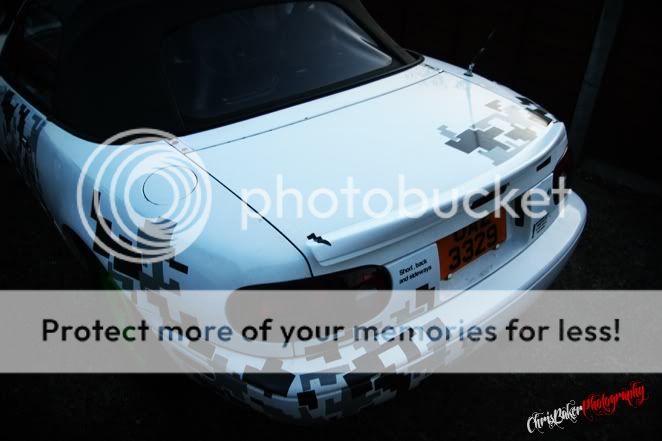

The diff ready to be welded!

A 40 mile round trip later and the diff is welded. The guy who done the welding said he tacked it and clamped it,and upon welding it the planet gears had moved. Which then made the centre out of line. Abit of filing/cutting and it'll line up with the grooves in the basket. So we done that and it still wouldnt fit,the shorter half shaft went in fine,but the other one wouldnt go in. With the planet gears out of line,the plate on top (where the larger part of the half shaft goes into) was also out of line,which meant the half shaft wouldnt go in.

So after stripping the diff back down again,we still couldnt think of any other way to fix it. Our only option was to source another set of planet gears (which was highly unlikely) or another whole diff.

Today i met up with my mate to collect the diff,where he then took it to H&S Performance where Mike managed to remove the planet gears and re-welded it. Having the half shafts there,they could fit them to make sure it was all lined up. Dale then went back to the garage and re-built the diff,which is now ready to go back onto the car which will be Friday.