-

Please only use these forums for blogs, they are not a discussion forum

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

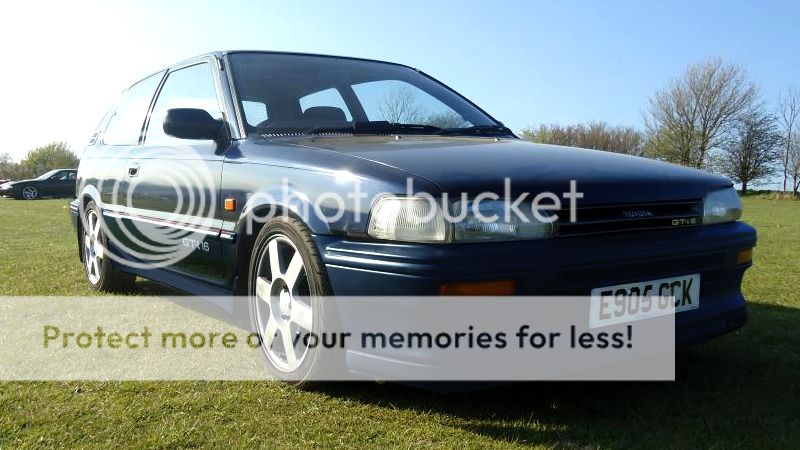

'88 Rolla Gti

- Thread starter will930

- Start date

can't believe in less than 6 months you've got it looking like a car..... Nicely done Will

thanks dude it looked like a shed before

ohhhhhhhhh!!!!!!!!!! lots of work to do.

-------------------------------------------------------------

2013 MERCEDES BENZ SL-CLASS

-------------------------------------------------------------

2013 MERCEDES BENZ SL-CLASS

righto finally ive uploaded the pics and have found time to write a worthy post!

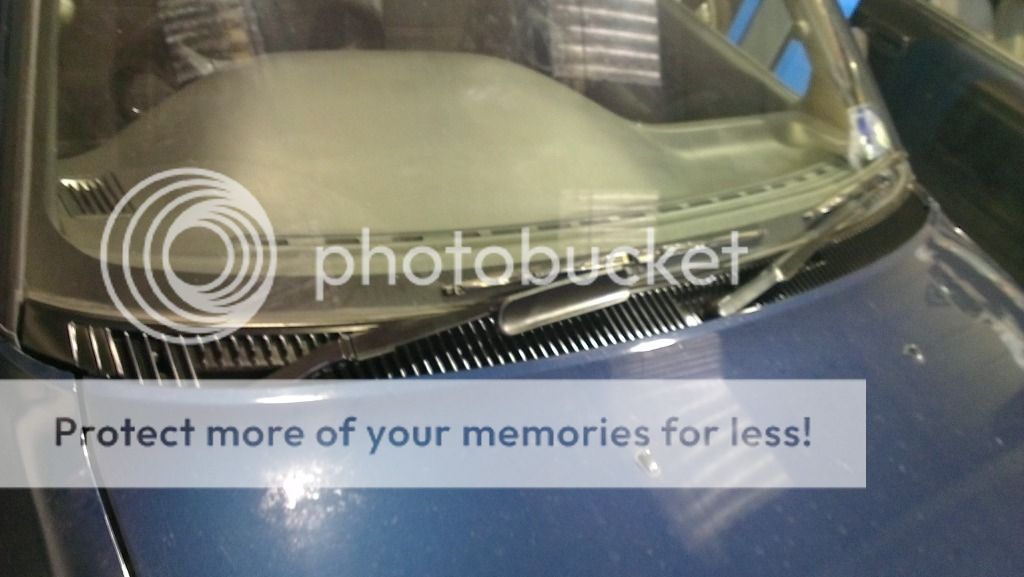

you may remember me saying i painted the scuttle panel and front wipers well here are the piccies

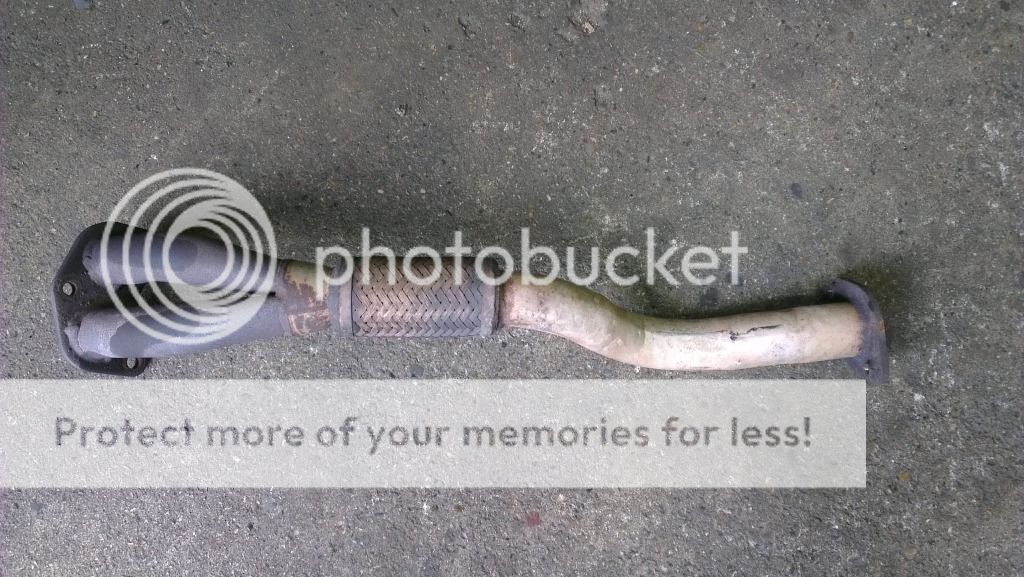

and then the exhaust down pipe here it is before and the blow was between where it goes from 2-1

then i welded it up using a series of 3 small 3mm steel plates, as i feel this could be a little neater than slowly building up the weld! i love welding too so it was no bother to me!

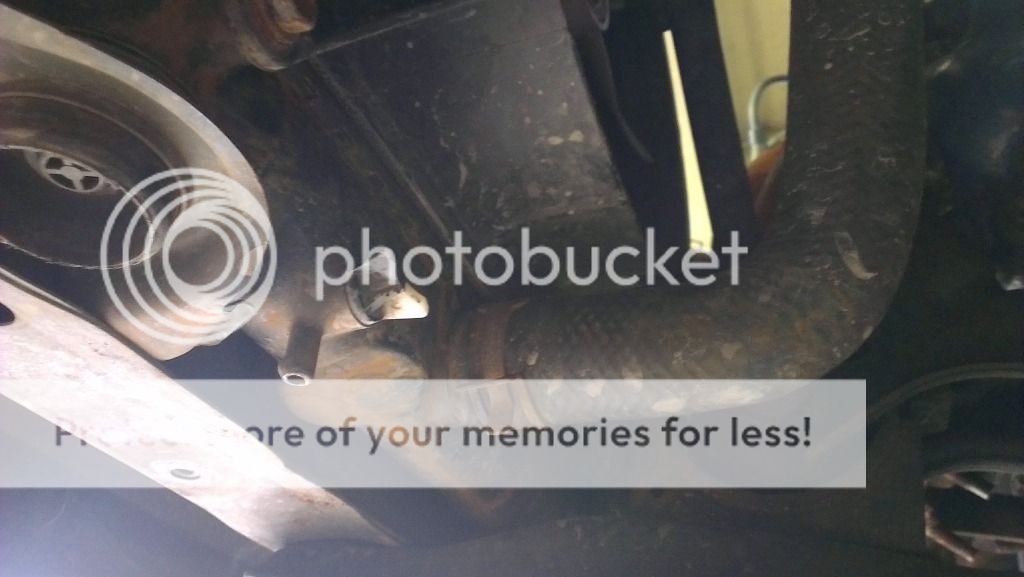

heres the evidence of the water leak! its quite obvious as you may be able to tell lol!

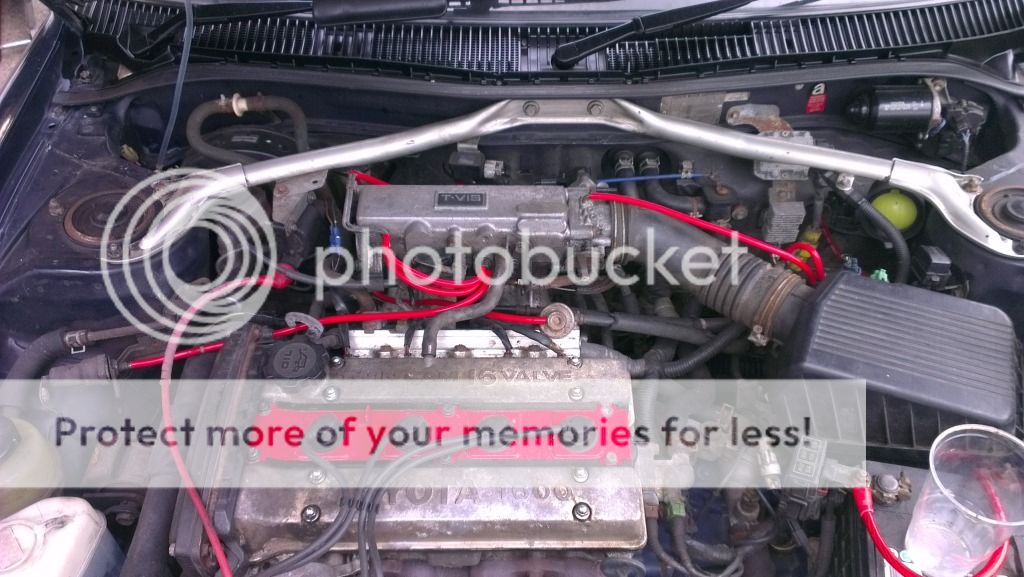

and i orderd some new vac lines, which i had laying around for ages but never got around to fitting untill the other day!

may be able to see the colour choice going on there lol

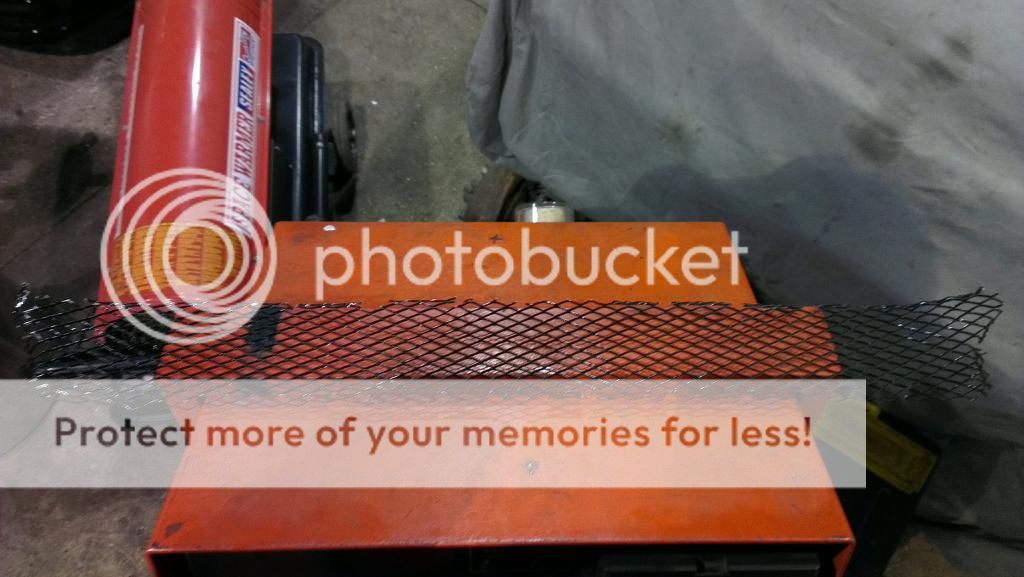

an open grill i got with my hoard

and then the broken tvis actuator module, which is a pain in the bum, as it now makes the engine light flash when its removed, however i bridged from the inlet mani to the round ufo valve under the mani and it seems to work ok and hold it closed.

but i really want to know if it will cause any issues if i were to swap my TVIS mani with a non-tvis mani using an adapter plate, such as power loss or confusing the ECU

you may remember me saying i painted the scuttle panel and front wipers well here are the piccies

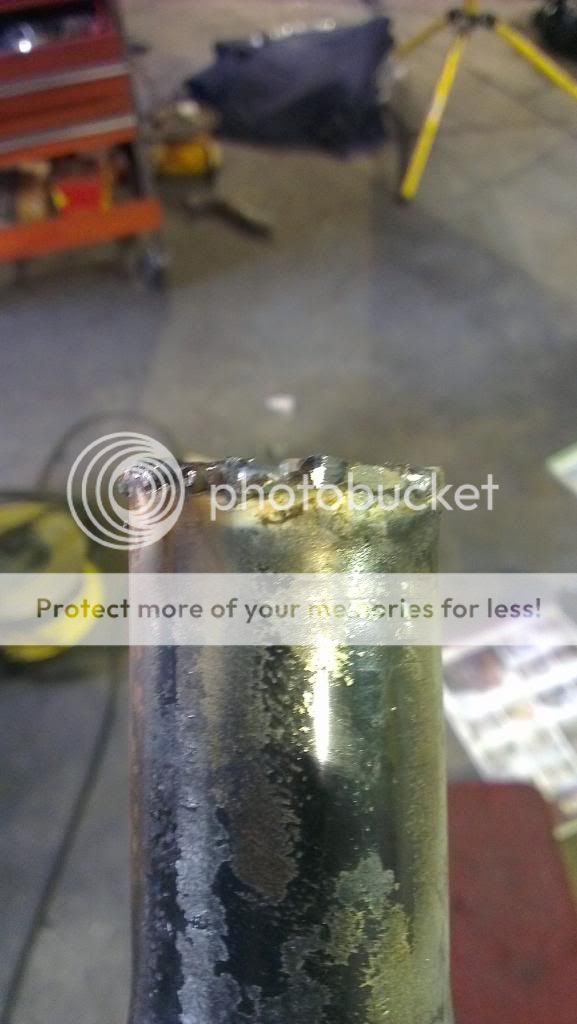

and then the exhaust down pipe here it is before and the blow was between where it goes from 2-1

then i welded it up using a series of 3 small 3mm steel plates, as i feel this could be a little neater than slowly building up the weld! i love welding too so it was no bother to me!

heres the evidence of the water leak! its quite obvious as you may be able to tell lol!

and i orderd some new vac lines, which i had laying around for ages but never got around to fitting untill the other day!

may be able to see the colour choice going on there lol

an open grill i got with my hoard

and then the broken tvis actuator module, which is a pain in the bum, as it now makes the engine light flash when its removed, however i bridged from the inlet mani to the round ufo valve under the mani and it seems to work ok and hold it closed.

but i really want to know if it will cause any issues if i were to swap my TVIS mani with a non-tvis mani using an adapter plate, such as power loss or confusing the ECU

well this is going to be a full on update, with pics as we all love pics

the car is still trooping on and have covered 10k since april meaning its due another oil change.

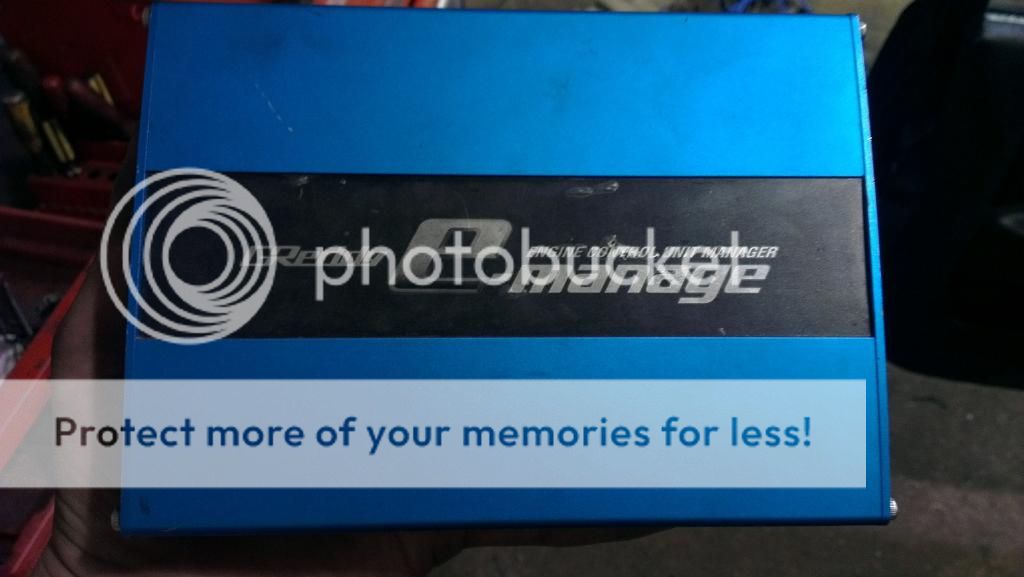

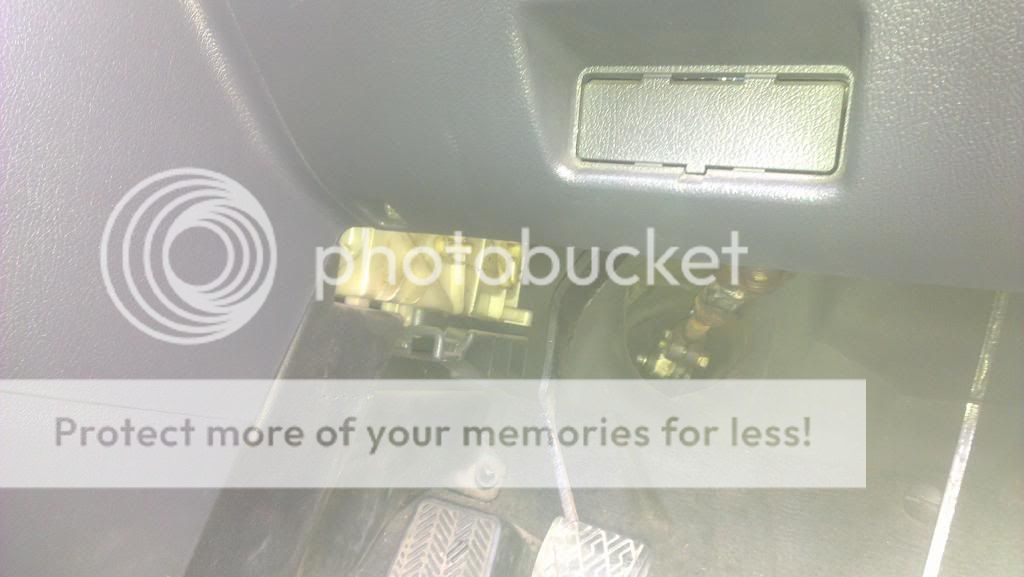

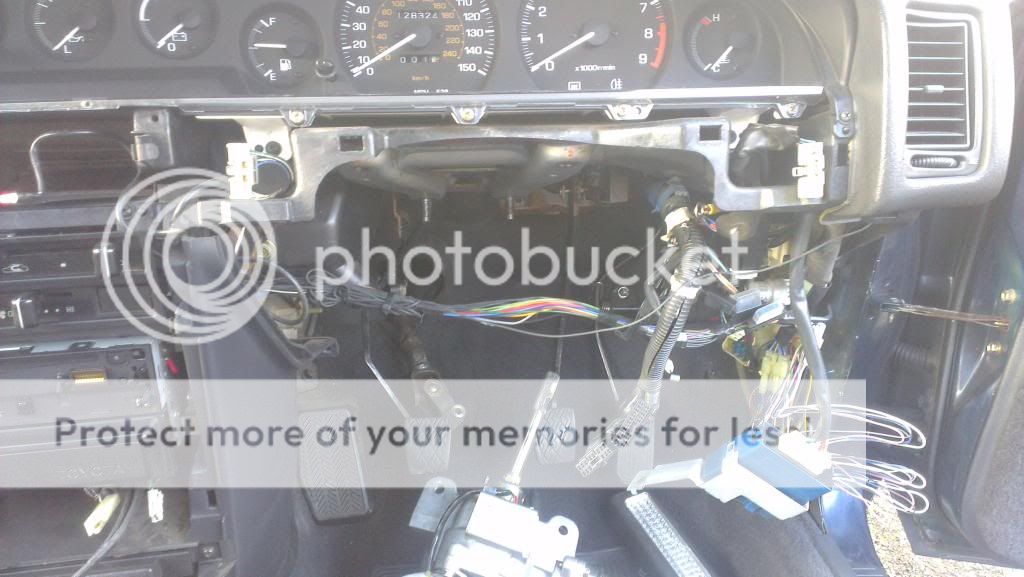

so firstly fitted the e-manage blue which is now all up and running, drilled a large hole and located it within the glove box

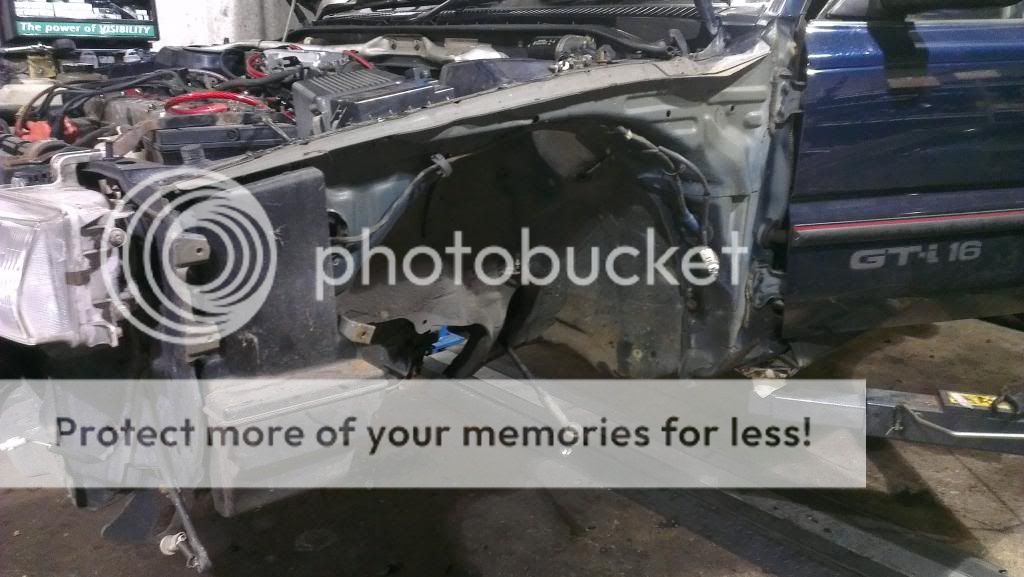

the other scrap corolla all stripped and awaiting its destiny of the scrap heap and the crusher, which got me half of what i paid for the car

the stripping begins

engine out

and stripped and loaded with other crap for scrap

garage full of spares micra still to fit back in

micra still to fit back in

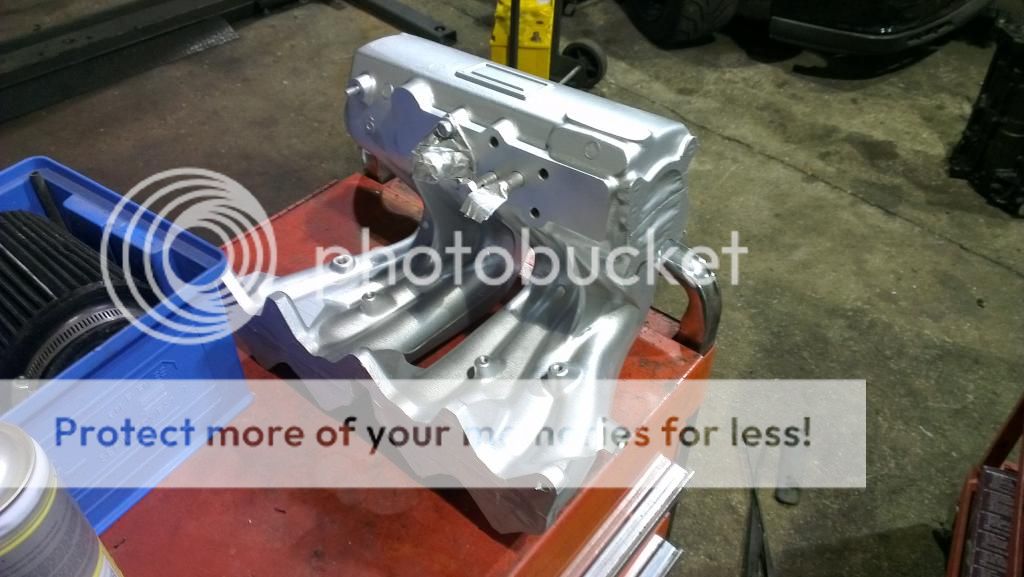

and i thought as i broke the T-VIS i thought id clean up the inlet mani and stuff from the spare engine to refit and get it working again

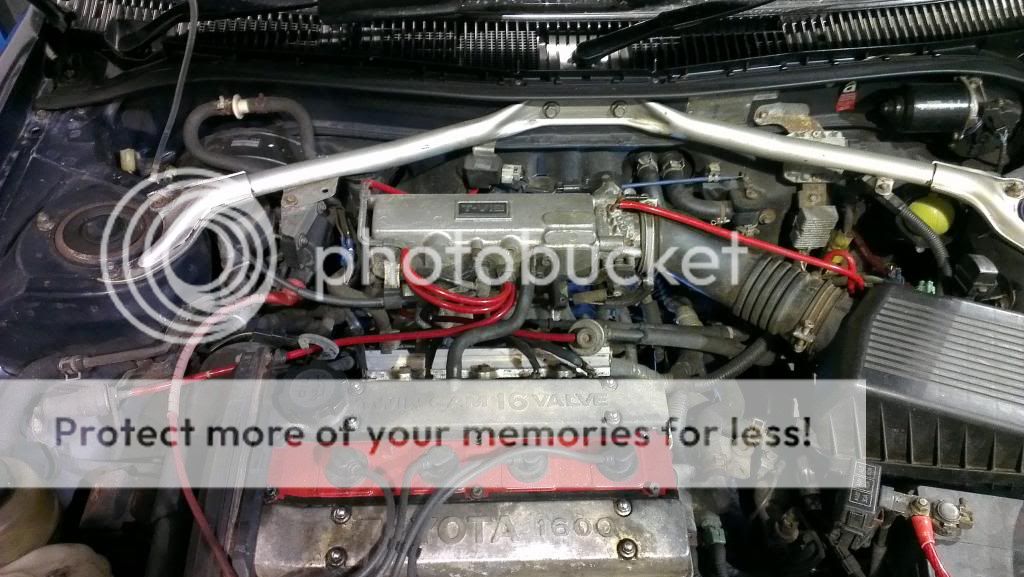

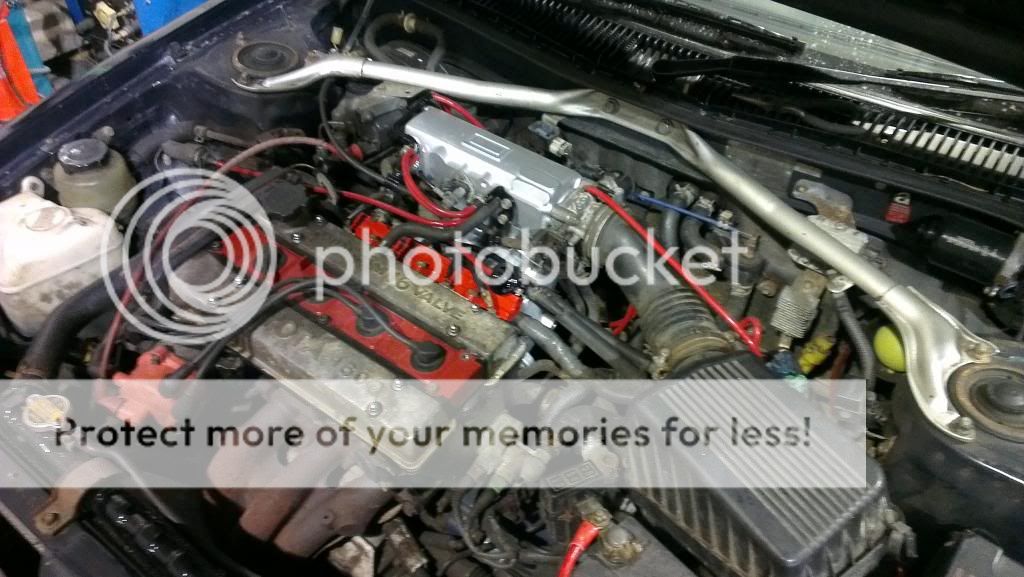

before

during painted

and fitted

before

comparison

after

also while i was at it, fitted my scorpion exhaust, which sounds awesome and looks awesome and makes the car feel much more torquey

along side everything else ive been working on the open mouth grill that came with a bunch of stuff i got previously

the mesh to go behind all made and cut and bent into shape prior to any prep of paint

and after a few coats of primer

hopefully the old girl will be getting mapped next week so i hope to see some decent figures, bearing in mind its virtually stock!

the car is still trooping on and have covered 10k since april meaning its due another oil change.

so firstly fitted the e-manage blue which is now all up and running, drilled a large hole and located it within the glove box

the other scrap corolla all stripped and awaiting its destiny of the scrap heap and the crusher, which got me half of what i paid for the car

the stripping begins

engine out

and stripped and loaded with other crap for scrap

garage full of spares

and i thought as i broke the T-VIS i thought id clean up the inlet mani and stuff from the spare engine to refit and get it working again

before

during painted

and fitted

before

comparison

after

also while i was at it, fitted my scorpion exhaust, which sounds awesome and looks awesome and makes the car feel much more torquey

along side everything else ive been working on the open mouth grill that came with a bunch of stuff i got previously

the mesh to go behind all made and cut and bent into shape prior to any prep of paint

and after a few coats of primer

hopefully the old girl will be getting mapped next week so i hope to see some decent figures, bearing in mind its virtually stock!

cherrytuner

K11 Blackmask

Great job with this Rolla , keep treating her nicely

squarepants

Ex. Club Member

excellent build!

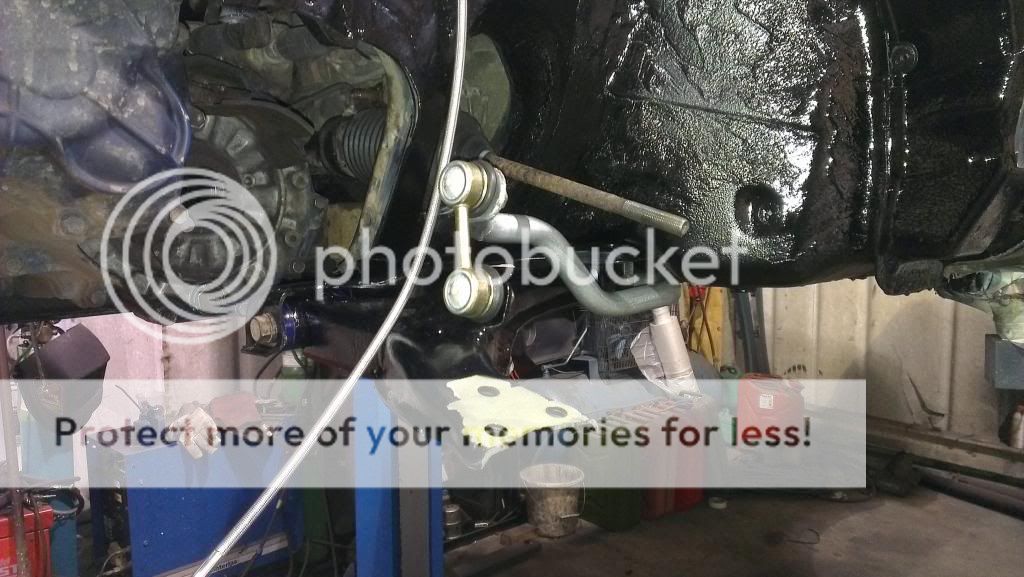

keep peeled lots happening still  full underside strip and rebuild inc...

full underside strip and rebuild inc...

full rust protection

freshly refurbished subframes

full poly bush set

new oe KYB shocks all round

new oe shock top mounts all round also kyb

lightly used apex lowering springs (40mm)

custom braided brake lines

fitting a known working steering rack

new drop links

then the underside will be done for now

full rust protection

freshly refurbished subframes

full poly bush set

new oe KYB shocks all round

new oe shock top mounts all round also kyb

lightly used apex lowering springs (40mm)

custom braided brake lines

fitting a known working steering rack

new drop links

then the underside will be done for now

so here goes, im going to break this dowen into posts over the next few days as i dont really have time to write it all in one night haha, this is going to be picture heavy!

so my main aim was to fully rust protect and upgrade the underside of my car, knowing how much they rust from the spares vehicle i had i thought theres no time like the present to hit it hard and now.

so the dates were set when i can use the workshop for a week to my hearts content as the boss was away, and pobviously he knew i was going to be doing this!

so the plan was to replace what i can and everything that moves virtually and to fully rust proof the underside of my car for the next week years at least.

so here we go,

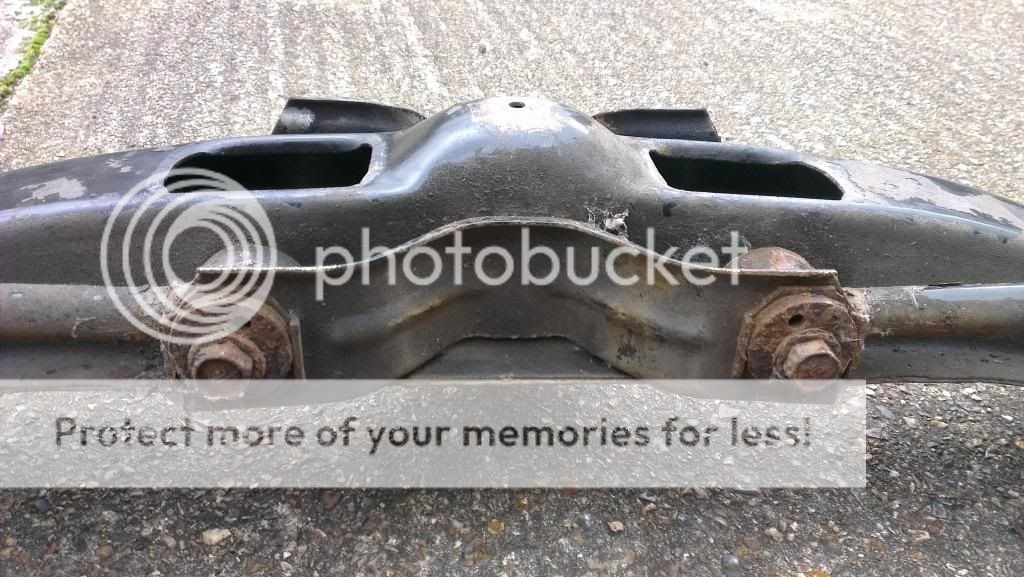

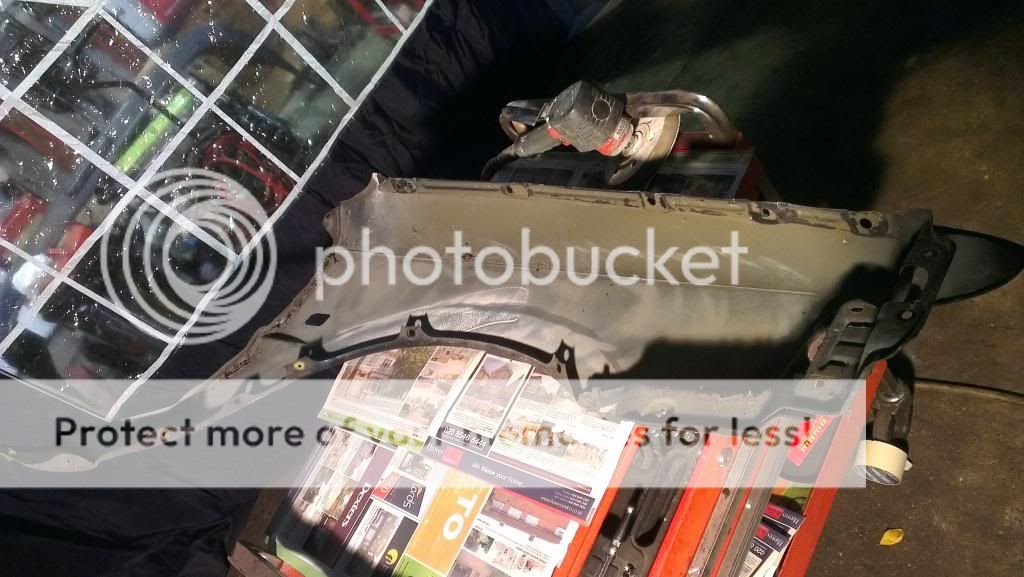

previously to the week i had, i stripped the rear subframe i had spare and removed all bushtings for shot blasting

making sure i know the adjustment setting for assembly

all the bushes removed using my works press, didnt really give too much bother

and then finally ready to be dropped off

upon assembly the two bolts that are located above the exhaust has rusted themselves solid to the insides of the bush so had to be cut. so i was hoping the ones on my cerrent subframe were all ok so that they can be used.

i had also fully stripped the front subframe and removed the bushes but i didnt bother to get any pictures of it.

Day One (Saturday)

so i had got to work after maybe 2pm with a car full of bits which all had to be unloaded before i could get the car onto the ramp.

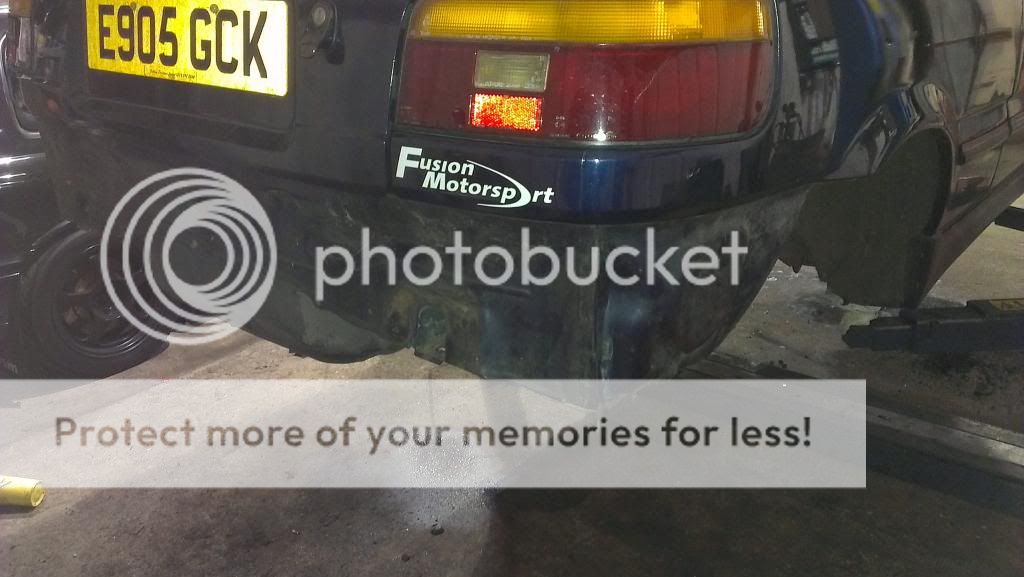

today my aim was to rip everything from the underside of the car, bumpers removed, petrol tank etc, which went well with only a handfull of snapped bolts on the front wings but nothing that cant be drilled out later on when im ready.

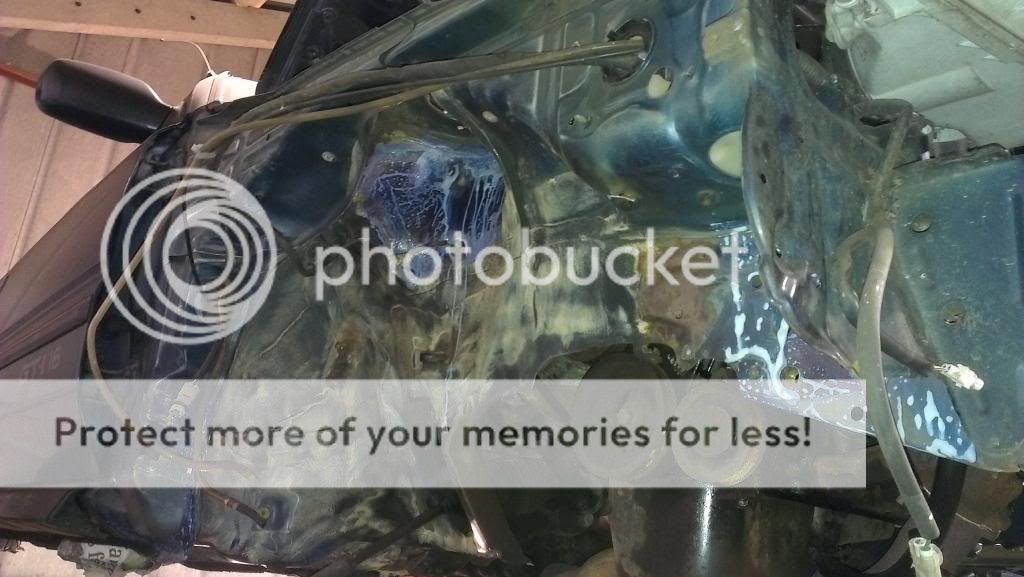

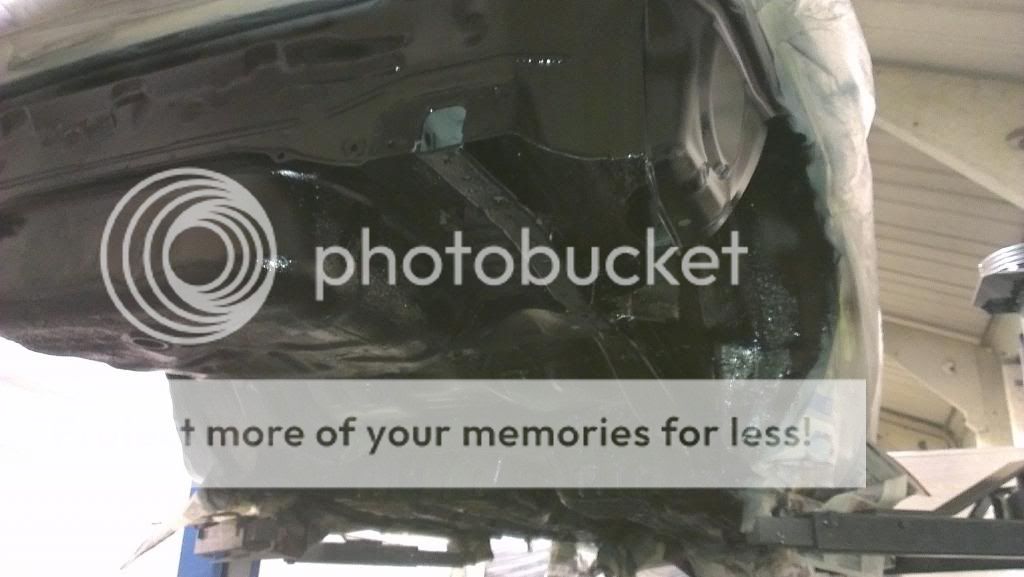

before i started

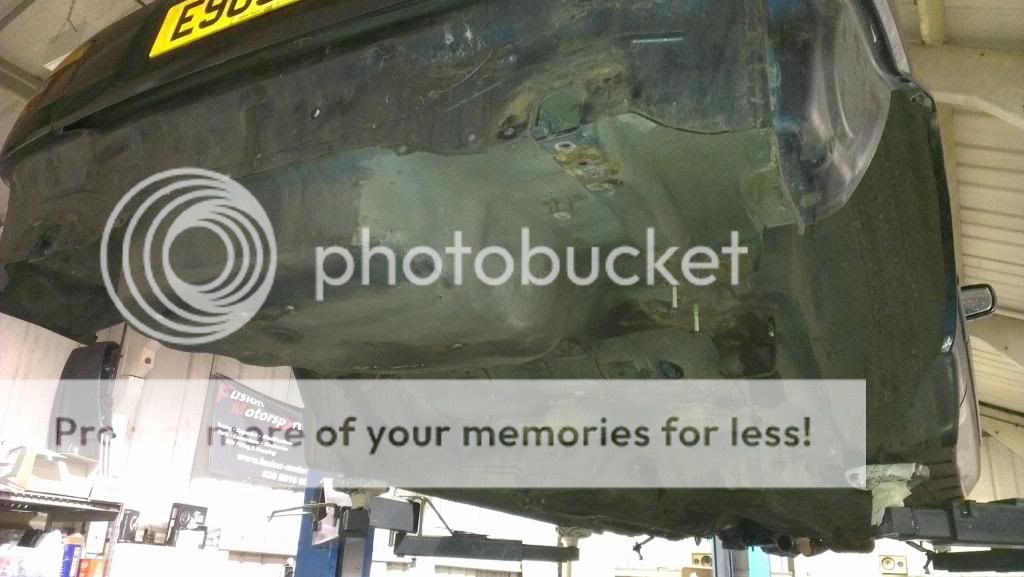

after about 5 hours i had the full underside stripped, once i get going i dont stop so we had a fully stripped car ready for the worst part of my life lol

so here it is stripped

this is the end of play on day one, proud of how well it went to be fair.

more to come

so my main aim was to fully rust protect and upgrade the underside of my car, knowing how much they rust from the spares vehicle i had i thought theres no time like the present to hit it hard and now.

so the dates were set when i can use the workshop for a week to my hearts content as the boss was away, and pobviously he knew i was going to be doing this!

so the plan was to replace what i can and everything that moves virtually and to fully rust proof the underside of my car for the next week years at least.

so here we go,

previously to the week i had, i stripped the rear subframe i had spare and removed all bushtings for shot blasting

making sure i know the adjustment setting for assembly

all the bushes removed using my works press, didnt really give too much bother

and then finally ready to be dropped off

upon assembly the two bolts that are located above the exhaust has rusted themselves solid to the insides of the bush so had to be cut. so i was hoping the ones on my cerrent subframe were all ok so that they can be used.

i had also fully stripped the front subframe and removed the bushes but i didnt bother to get any pictures of it.

Day One (Saturday)

so i had got to work after maybe 2pm with a car full of bits which all had to be unloaded before i could get the car onto the ramp.

today my aim was to rip everything from the underside of the car, bumpers removed, petrol tank etc, which went well with only a handfull of snapped bolts on the front wings but nothing that cant be drilled out later on when im ready.

before i started

after about 5 hours i had the full underside stripped, once i get going i dont stop so we had a fully stripped car ready for the worst part of my life lol

so here it is stripped

this is the end of play on day one, proud of how well it went to be fair.

more to come

Day Two (SUNDAY)

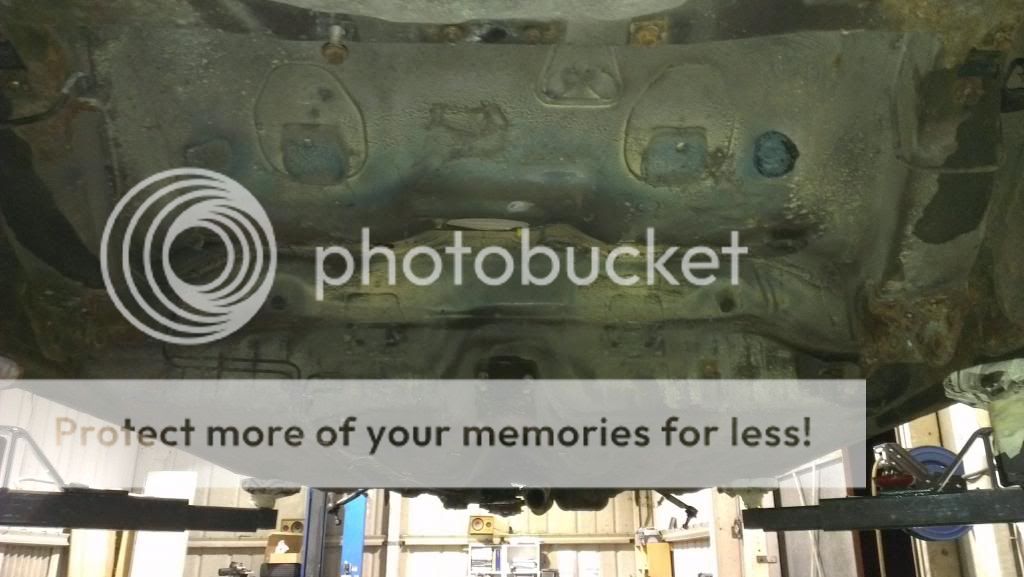

the main aim for today is to remove ANY flakey factory underseal and rust specs back to bear metal, as missing these vital point could cause problems in the future and rester under the fresh coatings ill be applying. i got there at a decent time on sunday armed with various bits and bobs including the following

- angle grinder with ebay wire wheel pieces

- drill with wire wheel set

- various sand papers

- wire brushes

this is what i believe id need so id been searching before and id got the wire wheel bits from ebay for a tenner thinking cheap crap, but no they just kept going and doing me well!

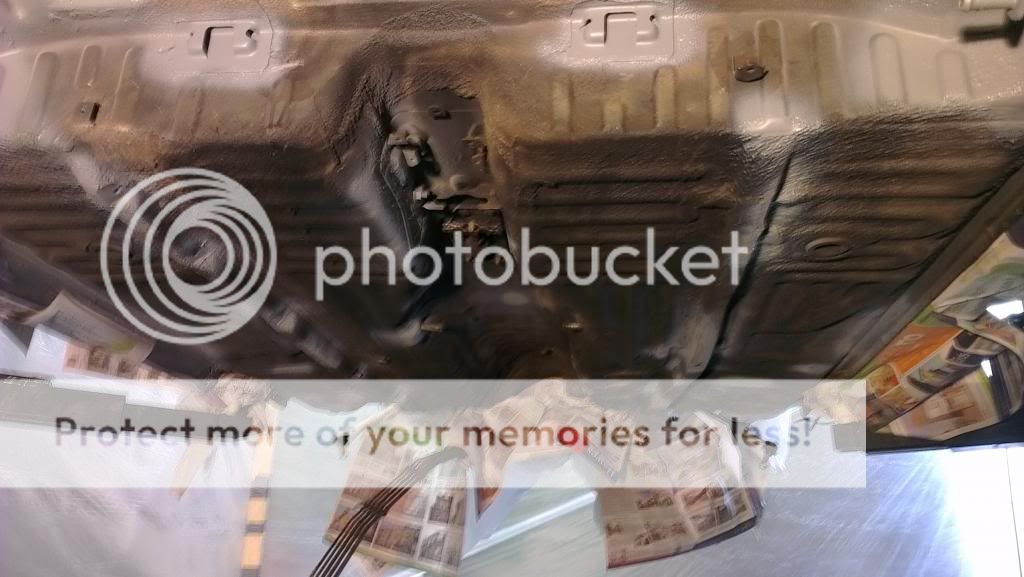

so here we go and got as much done as i could on the sunday and stayed till about 9.30 to get home intime for misfits

which is as far as i had got on sunday as i was experimenting with my technique, knowing what works best where, as good factory stonechip i didnt want to remove as i didnt need to as it seems like good stuff, so these areas i had simply wire brushed to death to remove as much crud and the 25 years of build up.

some point during the day my eye was quite sore from something obviously being in there, so after misfits had finished my missus encouraged me to go to the hospital as it was becoming painful, so after spending till 5am there and having a needle in my eye to have 2 specs of metal removed and this was wearing goggles, dust mask and a hat

stay tuned for more

the main aim for today is to remove ANY flakey factory underseal and rust specs back to bear metal, as missing these vital point could cause problems in the future and rester under the fresh coatings ill be applying. i got there at a decent time on sunday armed with various bits and bobs including the following

- angle grinder with ebay wire wheel pieces

- drill with wire wheel set

- various sand papers

- wire brushes

this is what i believe id need so id been searching before and id got the wire wheel bits from ebay for a tenner thinking cheap crap, but no they just kept going and doing me well!

so here we go and got as much done as i could on the sunday and stayed till about 9.30 to get home intime for misfits

which is as far as i had got on sunday as i was experimenting with my technique, knowing what works best where, as good factory stonechip i didnt want to remove as i didnt need to as it seems like good stuff, so these areas i had simply wire brushed to death to remove as much crud and the 25 years of build up.

some point during the day my eye was quite sore from something obviously being in there, so after misfits had finished my missus encouraged me to go to the hospital as it was becoming painful, so after spending till 5am there and having a needle in my eye to have 2 specs of metal removed and this was wearing goggles, dust mask and a hat

stay tuned for more

so its time for some more madness in the world of will!

Day Three (Monday)

after spending till 5am in hospital last night i felt very worse for wear and like i had a bad ass hang over so ended up staying in bed till mid day, then i drove to work with what felt like a hang over haha, but this was after i had picked up a new halogen bulb for me light as i coudlnt see anything towards the back of the car as obviously its by the wall and the lights are above! Doh

the extra potentially rust saving light

(sorry for poor pic quality all pics have been taken with my phone)

so now that i could see i had to carry on cleaning the rust, in which these rust a hell of alot more at the rear end than the front half

i found it to be very rusty around behind the fuel filler hole so i made sure i concentrated some efforts here

Once i feel that i was done i applied some Hamerite Kurust as ive heard some good reviews of it a liberally applied it everywhere that was bare metal with extra care being taken where i may not have been able to remove the rust fully

as you can see it working its magic

this area was very crusty

Day Three (Monday)

after spending till 5am in hospital last night i felt very worse for wear and like i had a bad ass hang over so ended up staying in bed till mid day, then i drove to work with what felt like a hang over haha, but this was after i had picked up a new halogen bulb for me light as i coudlnt see anything towards the back of the car as obviously its by the wall and the lights are above! Doh

the extra potentially rust saving light

(sorry for poor pic quality all pics have been taken with my phone)

so now that i could see i had to carry on cleaning the rust, in which these rust a hell of alot more at the rear end than the front half

i found it to be very rusty around behind the fuel filler hole so i made sure i concentrated some efforts here

Once i feel that i was done i applied some Hamerite Kurust as ive heard some good reviews of it a liberally applied it everywhere that was bare metal with extra care being taken where i may not have been able to remove the rust fully

as you can see it working its magic

this area was very crusty

by this time it was getting onto midnight, but i was determined to get to a stage i was happy with before i went home, this is due to my screwed sleep pattern

so i had proceeded with masking up which took a couple of hours

to stop all of the stuff in the workshop getting covered in paint and stuff i made a makeshift "tent"

the jurust has now dried and its now ready to take the first coat of paint

so i had proceeded with masking up which took a couple of hours

to stop all of the stuff in the workshop getting covered in paint and stuff i made a makeshift "tent"

the jurust has now dried and its now ready to take the first coat of paint

then i applied the primer i had bought, its a 1k anti rust primer

this was my final stage for tonight, as it was now about 2.30 am and i was feeling a little tired so i proceeded applying the primer but it wasnt flowing out of the gravity feed gun very well at all. realising it was far too thick, and i havent thinned it down at all haha, i added a 10% mix of thinners which allowed it to spray correctly.

ive noticed this area rusts hell of alot so i alot concentrated on this

after i had applied two coats of this it was gone 3 am it was time to get home and retire to bed, but i had ensured i covered every single area that was bare metal or any problems.

this was my final stage for tonight, as it was now about 2.30 am and i was feeling a little tired so i proceeded applying the primer but it wasnt flowing out of the gravity feed gun very well at all. realising it was far too thick, and i havent thinned it down at all haha, i added a 10% mix of thinners which allowed it to spray correctly.

ive noticed this area rusts hell of alot so i alot concentrated on this

after i had applied two coats of this it was gone 3 am it was time to get home and retire to bed, but i had ensured i covered every single area that was bare metal or any problems.

D

Deleted member

Guest

great ****in job man fear play

ur micra is a lovely clean car to..

ur micra is a lovely clean car to..

i must admit the micra is filthy and has been becuase i put it away like it lolgreat ####in job man fear play

ur micra is a lovely clean car to..

D

Deleted member

Guest

well mind they micra as much as ya do the corolla

Day Five (Wednesday)

so today i had a few bits today for my work which wasnt expected but took up most of my day due to unforseen issues so i havent been able to get too much done, but im still on track and managed to get a little bit done.

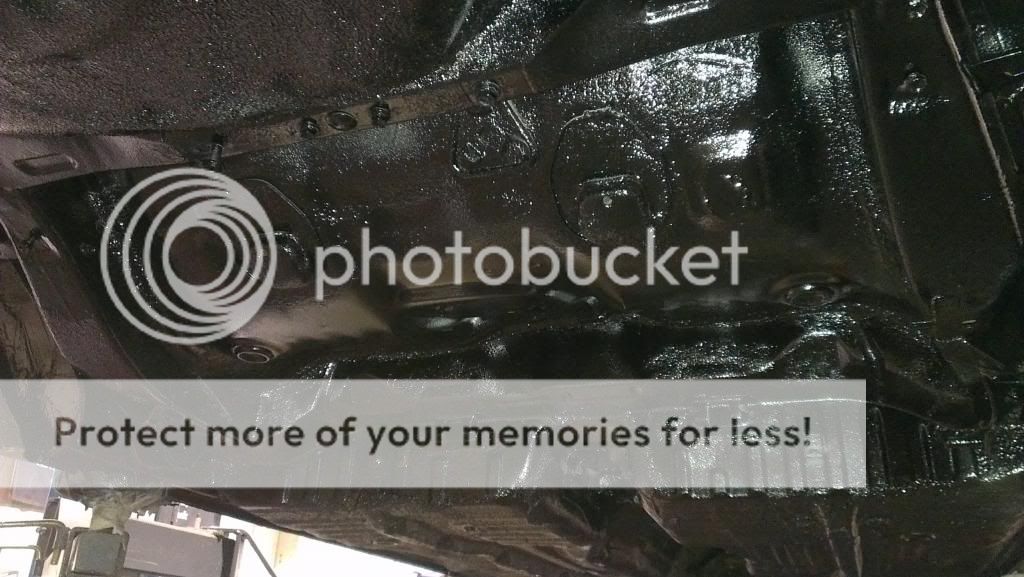

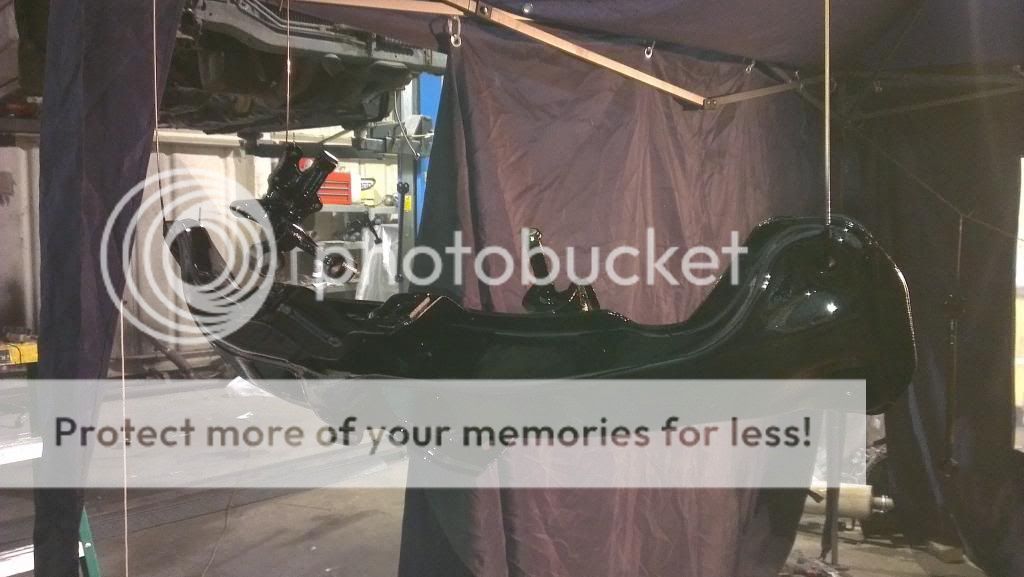

Which in reality worked out just fine as the subframes still arent ready and the grey stone chiop requires a while to cure properly before a top coat, due to some rules of the workshop and the landlord im not aloud to spray during working hours so i had to wait till the evning anyway, so i commenced with the spraying of gloss black in the 2k form, while spraying it over everything i can get to!

so here is a taster shot i uploaded to facebook the night i had done it

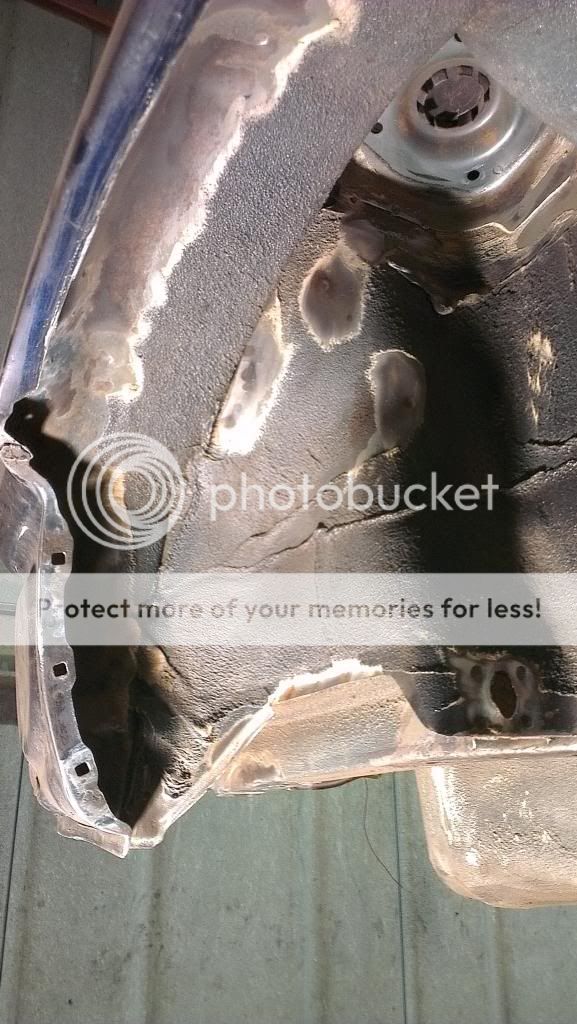

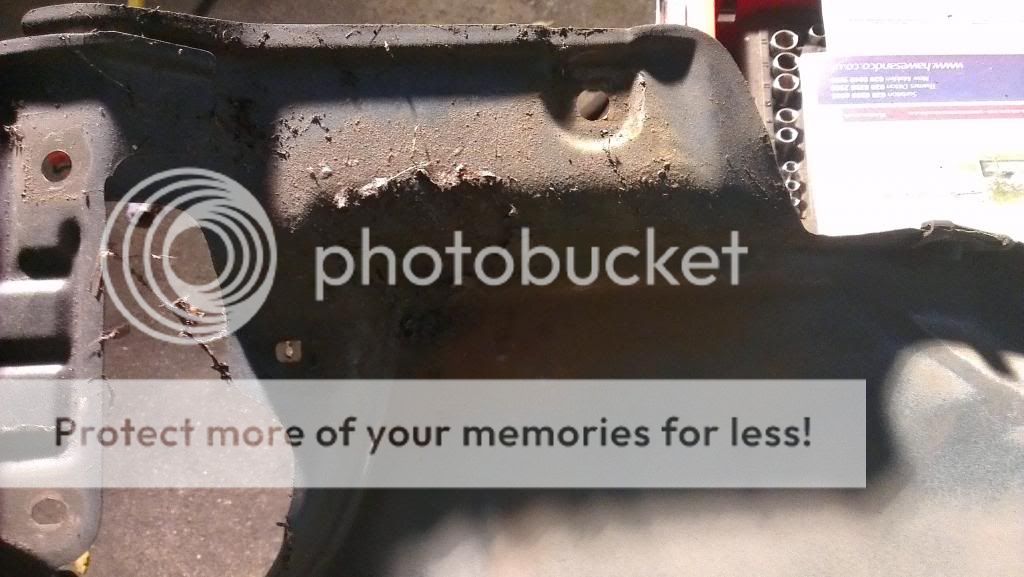

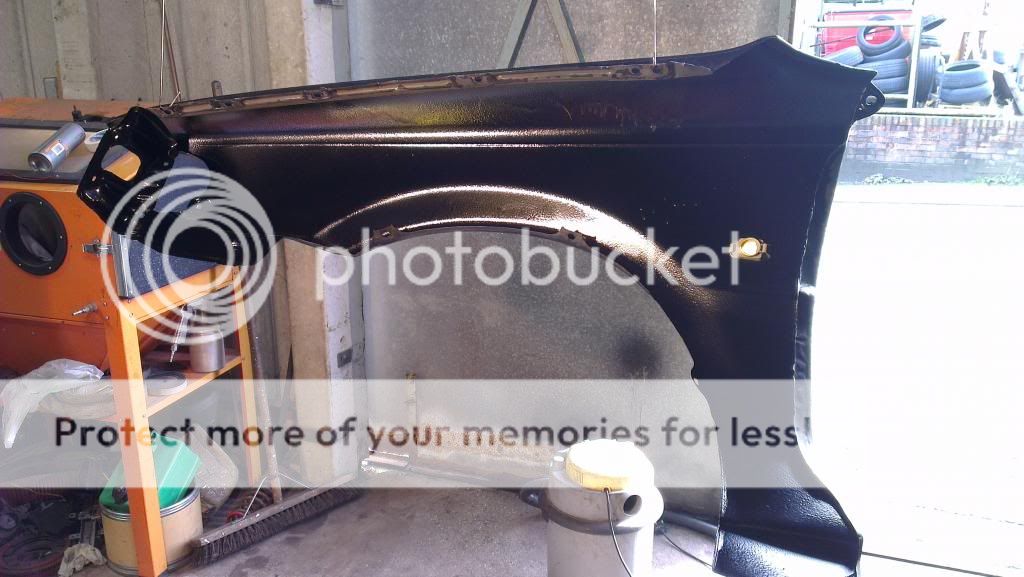

while this was curing before a second coat i went about and started working on the inner sides of my front wings which are recieving the same treatment, however one of them was rather rusty, and while cleaning it up from the inside it put 2 small holes through the wing and one being right on view.

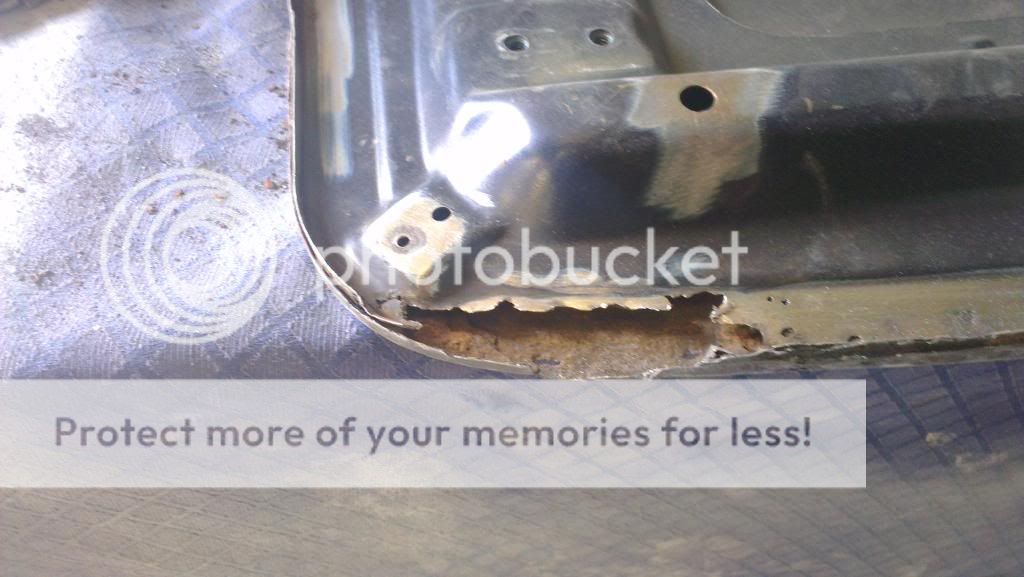

the rust

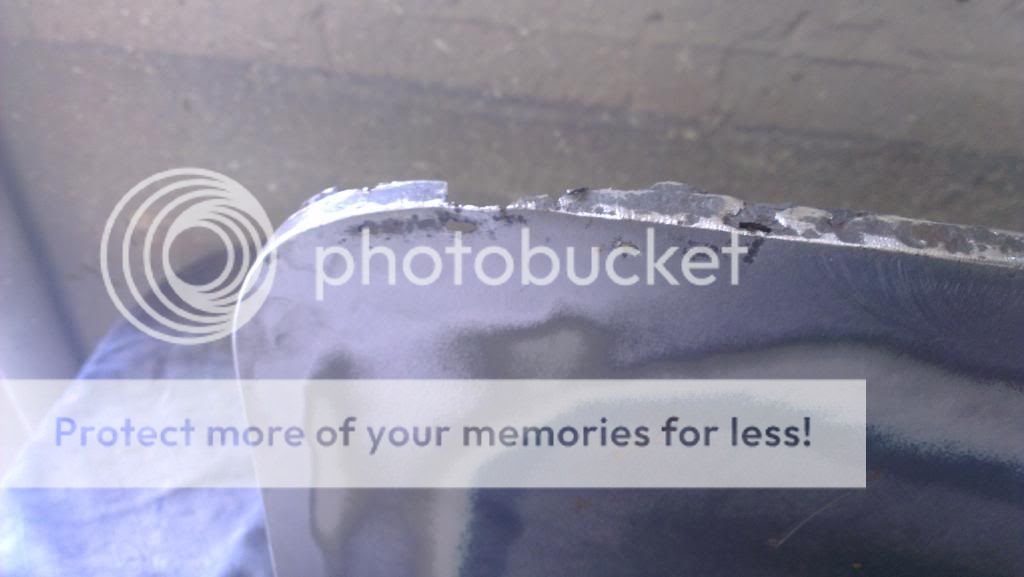

cleaned up

a focus on the area of rust, you can just about see where the holes are going through

from the outside

this is where the passenger side wing was put to one side where i could then work out what the next step should be for it, so i moved onto doing the other driver side front wing which was cleaned up and completely keyed and masked up ready for stone chip to be applied

stone chip applied all out the insides

which sadly is as far i had got pon the wednesday but thrusday become a bit more progressive as at this point i was gradually running out of time and starting to panic, with the hole in the front wing and the complete fail that is the fuel filler neck.

so today i had a few bits today for my work which wasnt expected but took up most of my day due to unforseen issues so i havent been able to get too much done, but im still on track and managed to get a little bit done.

Which in reality worked out just fine as the subframes still arent ready and the grey stone chiop requires a while to cure properly before a top coat, due to some rules of the workshop and the landlord im not aloud to spray during working hours so i had to wait till the evning anyway, so i commenced with the spraying of gloss black in the 2k form, while spraying it over everything i can get to!

so here is a taster shot i uploaded to facebook the night i had done it

while this was curing before a second coat i went about and started working on the inner sides of my front wings which are recieving the same treatment, however one of them was rather rusty, and while cleaning it up from the inside it put 2 small holes through the wing and one being right on view.

the rust

cleaned up

a focus on the area of rust, you can just about see where the holes are going through

from the outside

this is where the passenger side wing was put to one side where i could then work out what the next step should be for it, so i moved onto doing the other driver side front wing which was cleaned up and completely keyed and masked up ready for stone chip to be applied

stone chip applied all out the insides

which sadly is as far i had got pon the wednesday but thrusday become a bit more progressive as at this point i was gradually running out of time and starting to panic, with the hole in the front wing and the complete fail that is the fuel filler neck.

Day Six (Thursday)

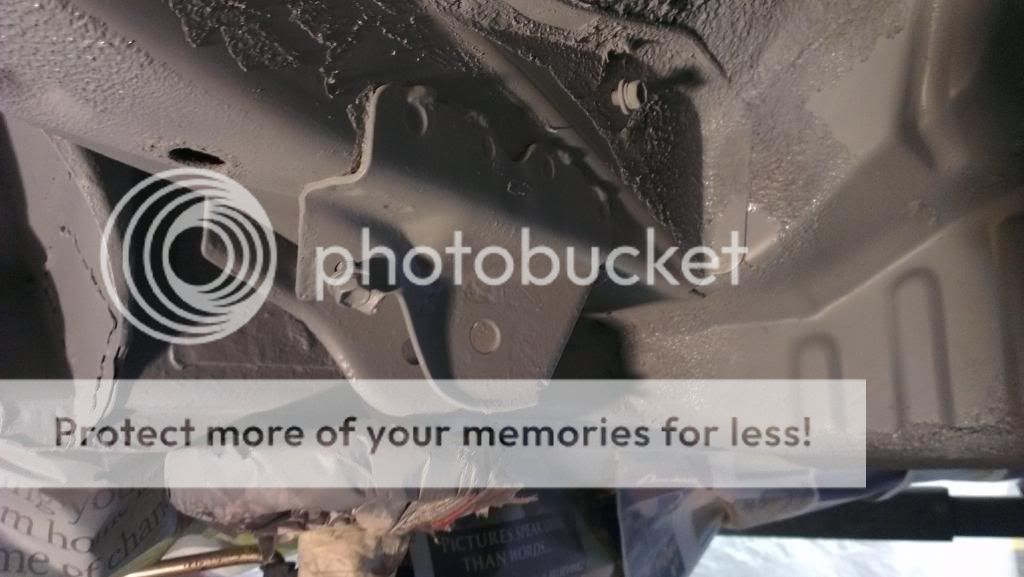

well today is the day that i fully demasked the car after the gloss black was sprayed so lets see the shiny like new results

looks good if i dont say so myself and being done properly i really dont think that the rust mites are going to surface for a good few years yet!

the front wing that i had stone chipped the night before i sprayed gloss black

end of part one as the contents if rather pic heavy and posts seems limited

well today is the day that i fully demasked the car after the gloss black was sprayed so lets see the shiny like new results

looks good if i dont say so myself and being done properly i really dont think that the rust mites are going to surface for a good few years yet!

the front wing that i had stone chipped the night before i sprayed gloss black

end of part one as the contents if rather pic heavy and posts seems limited

day six continued

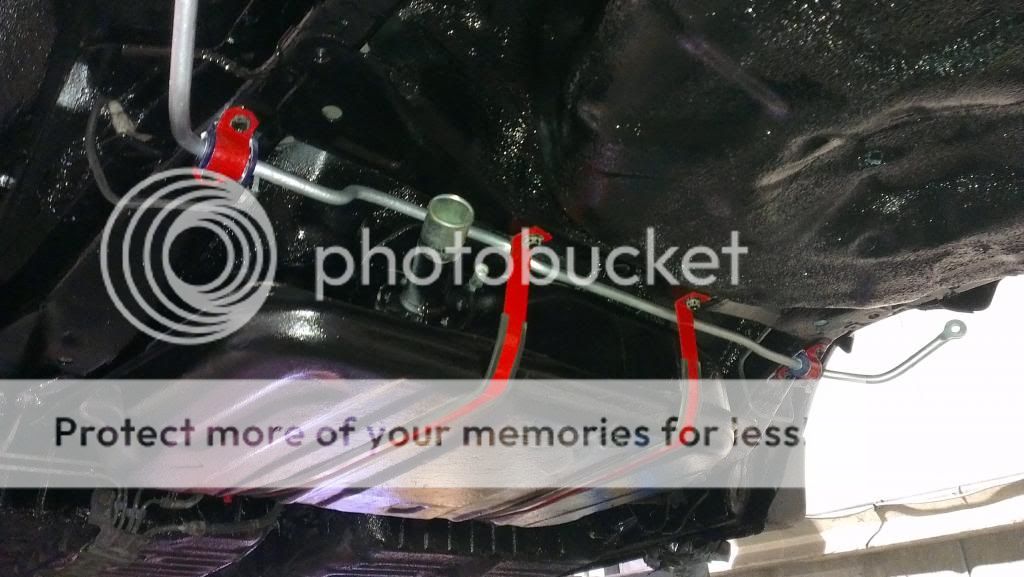

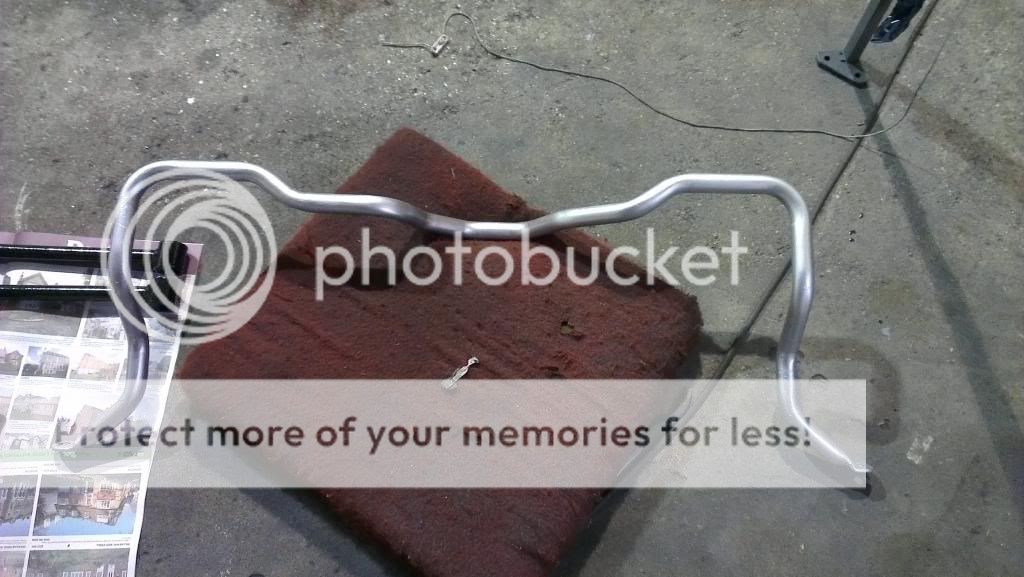

so as a few of the parts were now complete i thought that to save them from being damaged through storage, i thought id be best of fitting parts as i went along, i had cleaned up and painted the rear ARB brackets and tank straps in nissan micra red

and then had them fitted up with my new polybush kit! also painted the anti roll bad silver so dont be fooled its not a whiteline kit

the tank straps painted up and fitted

and here we are at the end of thursday, it seems short as during the day i went to a local shop near me called Think Automotive, to have my custom braided brake lines make with stainless ends and picked up from plexable fuel tank hose.

so as a few of the parts were now complete i thought that to save them from being damaged through storage, i thought id be best of fitting parts as i went along, i had cleaned up and painted the rear ARB brackets and tank straps in nissan micra red

and then had them fitted up with my new polybush kit! also painted the anti roll bad silver so dont be fooled its not a whiteline kit

the tank straps painted up and fitted

and here we are at the end of thursday, it seems short as during the day i went to a local shop near me called Think Automotive, to have my custom braided brake lines make with stainless ends and picked up from plexable fuel tank hose.

Day Seven (Friday)

so on friday i got the all important call that the subframes are ready and have been all shot blasted and given a coat of etch anti rust stuff to stop them from flash rusting!

here they are in the car xD

another picture of the front wing done as i was now ready to refit it and tidy up the wiring that runs along behind them.

all the subframe parts hanging ready for the first coat of etch primer

so i carried on part of the assembly after applying the first coat of anti rust primer to the subframes i thought that before i can put the front wing on ill get the tank all fitted as it was hanging below the car

fuel lines attached

having to remember the order i took apart at all times so that it can all go back toegteher just as easy, but not the tank is on it feels alot like progress!

now that the tank is fitted i lowered the car and got on with getting the front wing on so that was another part done and out of the way!

because half of the clips that retain the wiring busted upon removal i fancied using cable ties and managed to make a new hole near the existing and feed a cable tie through which kept it all neat and tidy and as you can see the front brake lines have been fitted

to fit the brake lines i fed them through and used the original clip to retain it to the chassis but due to nothing to stop the brake line being forced up i used cable ties to retain the brake line, the means that it helps to keep it sturdy without souly relying on the cable ties as thats always a nasty way of doing things.

image upwards of the drivers side front wing fitted

regarding the subframes i had managed to get them in 2 coats of anti rust primer and a coat of stone chip on all parts except from the hubs and the top side of the subframes, as i feel it may be wasted here. then i managed to get these painted in gloss black as time was getting on and i was also running out of workshop time.

this is the end of friday and i had once again got home at gone 11pm!

so on friday i got the all important call that the subframes are ready and have been all shot blasted and given a coat of etch anti rust stuff to stop them from flash rusting!

here they are in the car xD

another picture of the front wing done as i was now ready to refit it and tidy up the wiring that runs along behind them.

all the subframe parts hanging ready for the first coat of etch primer

so i carried on part of the assembly after applying the first coat of anti rust primer to the subframes i thought that before i can put the front wing on ill get the tank all fitted as it was hanging below the car

fuel lines attached

having to remember the order i took apart at all times so that it can all go back toegteher just as easy, but not the tank is on it feels alot like progress!

now that the tank is fitted i lowered the car and got on with getting the front wing on so that was another part done and out of the way!

because half of the clips that retain the wiring busted upon removal i fancied using cable ties and managed to make a new hole near the existing and feed a cable tie through which kept it all neat and tidy and as you can see the front brake lines have been fitted

to fit the brake lines i fed them through and used the original clip to retain it to the chassis but due to nothing to stop the brake line being forced up i used cable ties to retain the brake line, the means that it helps to keep it sturdy without souly relying on the cable ties as thats always a nasty way of doing things.

image upwards of the drivers side front wing fitted

regarding the subframes i had managed to get them in 2 coats of anti rust primer and a coat of stone chip on all parts except from the hubs and the top side of the subframes, as i feel it may be wasted here. then i managed to get these painted in gloss black as time was getting on and i was also running out of workshop time.

this is the end of friday and i had once again got home at gone 11pm!

Day Eight (saturday)

now the pressure was falling on me because everything was painted and essentially ready to be fitted.

i had the missus with me today to give a hand with a few bits and the first task was to fit the steering rack from the corolla i broke and scrapped which enables me to have power steering at long last after both the seals failed on its way to the mot pouring all the fluid everywhere.

then i thought it best to collapse the gazebo to make more light and space,

subframes on the floor awaiting assembly with new polybushings

the areas you see i green are areas i didnt apply paint as these are contact surfaces for the rear wheel bearing etc

front ARB rubbed down and painted

with the new steering rack fitted, i assembled the front subframe with the fresh bushings and antiroll bar and new drop links and listed this onto the car, the bolts gave issues but assebling everything with copper slip always makes life easier now and in the future.

so moving on a little bit i had managed to fit the hand brake cables and the exhaust once again, which all went together fine after id put the hand brake cables on the wrong sides whoopsie

so moving on to later on in the day where i had assembled my:

new shocks

new top mounts

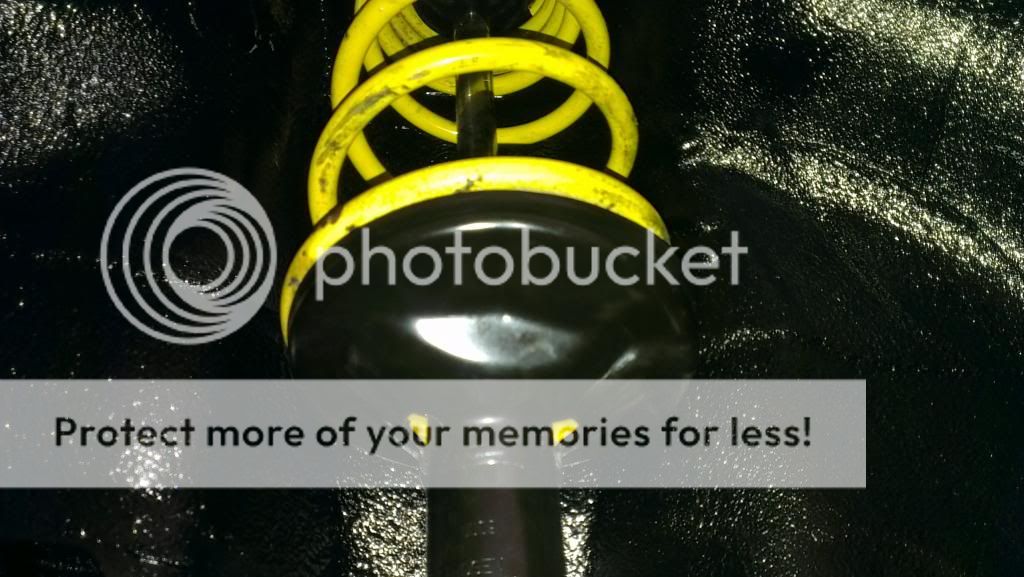

lowering springs (which are for an e11 corolla and not e9 so the rears are wrong annoyingly!

the springs being wrong were not my only my springs were wrong the rear subframe bushs were wrong so i had to put my old one back on temporarily untill i could sort them out which is a bummer but nother to worry about for now.

as you can see the rear end fully assembled now

here you can also see where the rear spring doesnt sit correctly

this is a quick pic which sums up the rear shocks which simply stay down and made bubbles too lol

now the pressure was falling on me because everything was painted and essentially ready to be fitted.

i had the missus with me today to give a hand with a few bits and the first task was to fit the steering rack from the corolla i broke and scrapped which enables me to have power steering at long last after both the seals failed on its way to the mot pouring all the fluid everywhere.

then i thought it best to collapse the gazebo to make more light and space,

subframes on the floor awaiting assembly with new polybushings

the areas you see i green are areas i didnt apply paint as these are contact surfaces for the rear wheel bearing etc

front ARB rubbed down and painted

with the new steering rack fitted, i assembled the front subframe with the fresh bushings and antiroll bar and new drop links and listed this onto the car, the bolts gave issues but assebling everything with copper slip always makes life easier now and in the future.

so moving on a little bit i had managed to fit the hand brake cables and the exhaust once again, which all went together fine after id put the hand brake cables on the wrong sides whoopsie

so moving on to later on in the day where i had assembled my:

new shocks

new top mounts

lowering springs (which are for an e11 corolla and not e9 so the rears are wrong annoyingly!

the springs being wrong were not my only my springs were wrong the rear subframe bushs were wrong so i had to put my old one back on temporarily untill i could sort them out which is a bummer but nother to worry about for now.

as you can see the rear end fully assembled now

here you can also see where the rear spring doesnt sit correctly

this is a quick pic which sums up the rear shocks which simply stay down and made bubbles too lol

Day Nine (Sunday)

well today was general tidy up day but i still had a few bits to do and get done

first up was the fuel filler neck which i knew i had to do properly to avoid it going wrong, so i worked out the length i had to work with and chopped away all the potentially rusty metal to ensure its all happy so ill let the pics do the talking

here it is mocked up, even though the metal is still it sits well behind the fuel flap which is great

the hose on the tank end

as i was happy with that i wanted to add a lip to the filler neck end of the pipe to help the clamp with the pipe and to make it tighter

i then gave it a quick coats of paint and fitted it up as you can see

the next stage that i remember was to repair the front wing so that it can be painted and fitted, so i welded in a new plate, added fibreglass filler and then was ready for primer

which is as far as i have got and there is more to come which has been done around everything, such as wheels and tyres etc

well today was general tidy up day but i still had a few bits to do and get done

first up was the fuel filler neck which i knew i had to do properly to avoid it going wrong, so i worked out the length i had to work with and chopped away all the potentially rusty metal to ensure its all happy so ill let the pics do the talking

here it is mocked up, even though the metal is still it sits well behind the fuel flap which is great

the hose on the tank end

as i was happy with that i wanted to add a lip to the filler neck end of the pipe to help the clamp with the pipe and to make it tighter

i then gave it a quick coats of paint and fitted it up as you can see

the next stage that i remember was to repair the front wing so that it can be painted and fitted, so i welded in a new plate, added fibreglass filler and then was ready for primer

which is as far as i have got and there is more to come which has been done around everything, such as wheels and tyres etc

well i didnt mean to leave it a month but the car is still alive and fast aproaching 120k and 15of that in my ownership since this time ish last year

well the bumb stops are working but im simply sitting on them so its just not great, no suspension travel at all so i dont know what im going to do, chop down the stops i think but having only having about 2 inches of travel in the first place just isnt going to work! so im going to have to look into alternative FAST as its not going to do anything any good what so ever!

well onto the pics from where i left off before,

the car sitting outside my work waiting for the correct sprngs to come, and the front wing to be painted!

then i managed to sort out the correct bushings for the rear subframe so i built that up, old vs new

the right springs on the right and the wrong springs on the left

whiloe the car was sitting there on fresh rubber the new rubber being 195/45/16 Yokohama S.Drive one of the tyres went flat, which i thought thats odd, took to the tyre place to discover this! mega poo poo so back on with the old wheels

mahoosive crack, all is not lost as the wheels were terribly painted in white with no prep

so now all the underbody treatment has had time to harden i managed to waxoyl the entire underside, going into all the cavities and box sections to prevent the iminent threat of it rusting from the inside out! which most jap tin always seems to do! as it was a chilly night i had the heaters on and to get the wax in the form of Bilt-Hammer S50 i used boiling water out of the hettle for about an hour topping it up to make it flow nicely

covering up the floor to avoid making more mess i coated the lot,

then once fitted back together i popped along to the garge locally which dones proper 4 wheels individual alignment! which improved matters alot lol

well thats it for now, i drove it around for a while and have coverd about 1200miles and all is well apart from the front end, well the entire car banging away and i add bumpstops and it simply sits on them, the stops cant be any more than 2inches and bam all movement gone, not too sure what else i can do other that cut them down but im still going to have naff all suspension travel.

stay tuned though there is more!

well the bumb stops are working but im simply sitting on them so its just not great, no suspension travel at all so i dont know what im going to do, chop down the stops i think but having only having about 2 inches of travel in the first place just isnt going to work! so im going to have to look into alternative FAST as its not going to do anything any good what so ever!

well onto the pics from where i left off before,

the car sitting outside my work waiting for the correct sprngs to come, and the front wing to be painted!

then i managed to sort out the correct bushings for the rear subframe so i built that up, old vs new

the right springs on the right and the wrong springs on the left

whiloe the car was sitting there on fresh rubber the new rubber being 195/45/16 Yokohama S.Drive one of the tyres went flat, which i thought thats odd, took to the tyre place to discover this! mega poo poo so back on with the old wheels

mahoosive crack, all is not lost as the wheels were terribly painted in white with no prep

so now all the underbody treatment has had time to harden i managed to waxoyl the entire underside, going into all the cavities and box sections to prevent the iminent threat of it rusting from the inside out! which most jap tin always seems to do! as it was a chilly night i had the heaters on and to get the wax in the form of Bilt-Hammer S50 i used boiling water out of the hettle for about an hour topping it up to make it flow nicely

covering up the floor to avoid making more mess i coated the lot,

then once fitted back together i popped along to the garge locally which dones proper 4 wheels individual alignment! which improved matters alot lol

well thats it for now, i drove it around for a while and have coverd about 1200miles and all is well apart from the front end, well the entire car banging away and i add bumpstops and it simply sits on them, the stops cant be any more than 2inches and bam all movement gone, not too sure what else i can do other that cut them down but im still going to have naff all suspension travel.

stay tuned though there is more!

Right chaps and chapesses sit down and grab a tea or coffe and some biscuits!

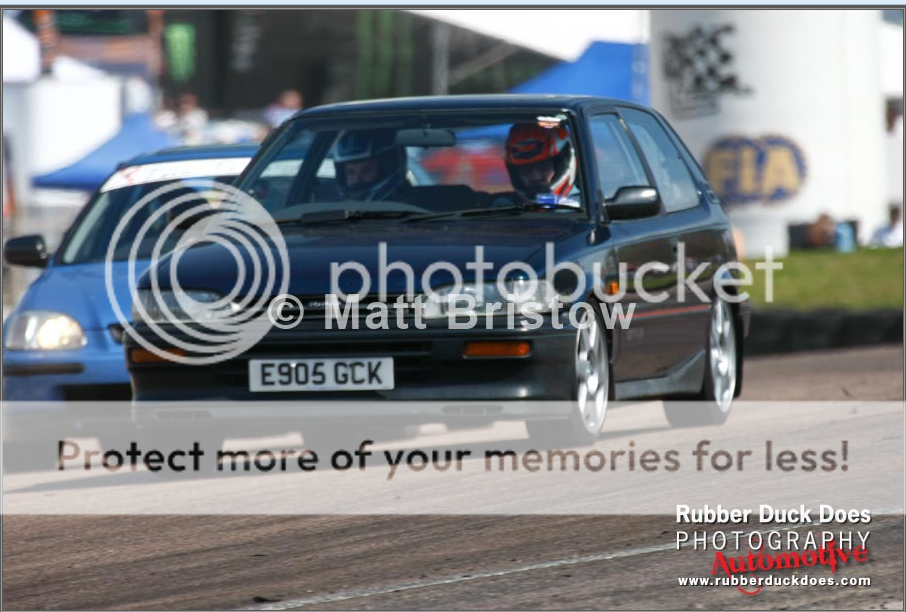

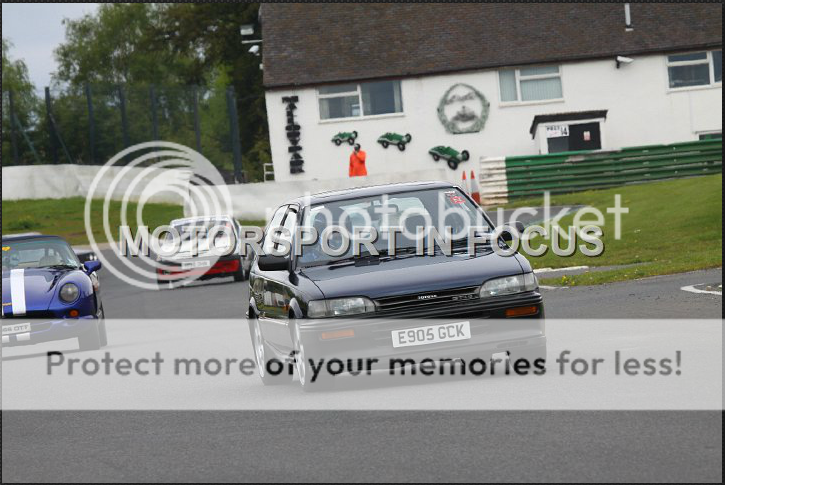

since the MOT ive been quiet but then suddly started rushing around, as i decided to arrange for my customers cars through work to attend BHP Performance Show at Lydden Hill. (started to arrange 6 days before the deadline) however without much ado i managed to scrape 10 cars together, and im sure you know what its like for this type of thing.

so a week before and the booking form in i started panicing about brakes and the such but more on that later... knowing there was alot of track time available i had to get my thinking cap on, and had my bucket seat sitting around, and as you can imagine the day before the show i decided to fit it hehe

simply because the original seat sat too night for me specially with a helmet on!

simply because the original seat sat too night for me specially with a helmet on!

no during fitting images but heres a couple of it fitted from the show its self!

its a little furthur back than id have hoped but i can control the car just fine and its comfy, all racey like hehe

the day before while sorting some bits and bobs out i found a shop open that sold motorbike gear and got a decent fitting helmet for £29.99 sweet!

day of the show got there around 7.30 am in thick fog lol and the first to arrive at the stand so rushed off to get my track time

decided on two sessions in total which ended up being three! lol

decided on two sessions in total which ended up being three! lol

when i eventually got back from the track booking more had arrived

so my boss in the grey pulsar managed to spin a bottom end bearing after about 10 mins on track which was a bummer!

so my first track session at 10.45am my third tme on track ever and first on this track! heres my vids from that session

gopro mounted on interior light mount

and phone mounted on screen

at this point i learnt my bosses engine and popped so i thought well ill consider taking his last session at 4.15. but not untill id done my 2.15 session which is as follows

i had my dad riding shotgun, i knew the track better and knew how the car was going to react nothing could be better, untill his travel sickness kicked in and had to abandon track!

gopro mounted on offside rear quarter

and some accompanying images ive found

at this point the car was still behaving perfectly, and couldnt have asked for more from it, so i decided what more harm could another session do eh? so more pics from this one where i took a customer out, which at this point i was pushing hard and going fast getting all the apexs etc

during the last track session one of our pulsars let go and dumped its oil, which made things interesting

now on a track where three of the four bends and right handers you can imagine what im about to post!

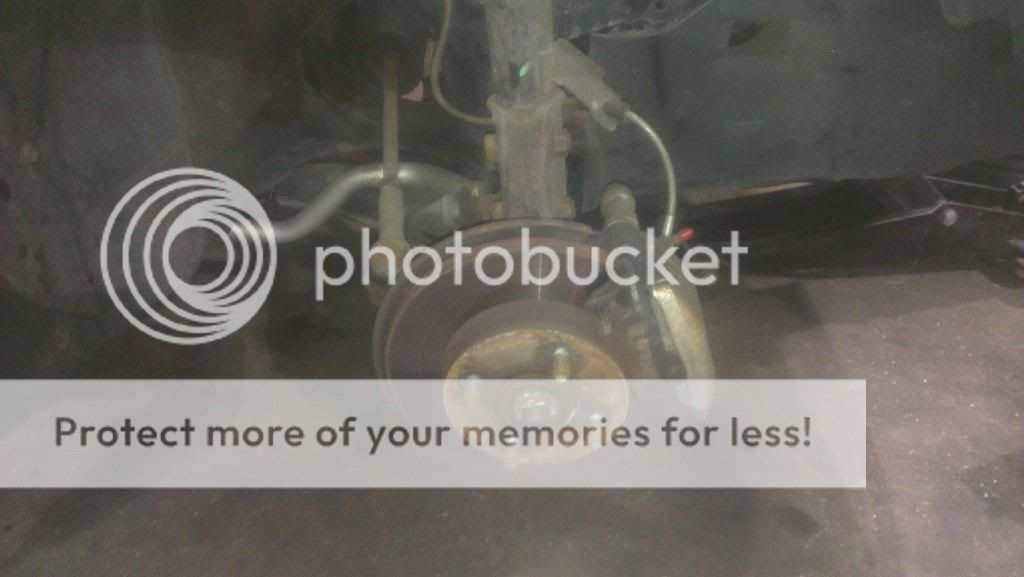

OSF

NSF

can you make out the difference? hehe

and to finalise some pics i took

well overall it was a great day, and the car was faultless, but theres are a couple of things id change, a little more power and a little less roll ARBS ftw

as i was underpowered compared to most but could corner as fast as the rest!

heres the link to my photobucket with some more pics

since the MOT ive been quiet but then suddly started rushing around, as i decided to arrange for my customers cars through work to attend BHP Performance Show at Lydden Hill. (started to arrange 6 days before the deadline) however without much ado i managed to scrape 10 cars together, and im sure you know what its like for this type of thing.

so a week before and the booking form in i started panicing about brakes and the such but more on that later... knowing there was alot of track time available i had to get my thinking cap on, and had my bucket seat sitting around, and as you can imagine the day before the show i decided to fit it hehe

no during fitting images but heres a couple of it fitted from the show its self!

its a little furthur back than id have hoped but i can control the car just fine and its comfy, all racey like hehe

the day before while sorting some bits and bobs out i found a shop open that sold motorbike gear and got a decent fitting helmet for £29.99 sweet!

day of the show got there around 7.30 am in thick fog lol and the first to arrive at the stand so rushed off to get my track time

when i eventually got back from the track booking more had arrived

so my boss in the grey pulsar managed to spin a bottom end bearing after about 10 mins on track which was a bummer!

so my first track session at 10.45am my third tme on track ever and first on this track! heres my vids from that session

gopro mounted on interior light mount

and phone mounted on screen

at this point i learnt my bosses engine and popped so i thought well ill consider taking his last session at 4.15. but not untill id done my 2.15 session which is as follows

i had my dad riding shotgun, i knew the track better and knew how the car was going to react nothing could be better, untill his travel sickness kicked in and had to abandon track!

gopro mounted on offside rear quarter

and some accompanying images ive found

at this point the car was still behaving perfectly, and couldnt have asked for more from it, so i decided what more harm could another session do eh? so more pics from this one where i took a customer out, which at this point i was pushing hard and going fast getting all the apexs etc

during the last track session one of our pulsars let go and dumped its oil, which made things interesting

now on a track where three of the four bends and right handers you can imagine what im about to post!

OSF

NSF

can you make out the difference? hehe

and to finalise some pics i took

well overall it was a great day, and the car was faultless, but theres are a couple of things id change, a little more power and a little less roll ARBS ftw

as i was underpowered compared to most but could corner as fast as the rest!

heres the link to my photobucket with some more pics

hello, good morning from a sunburnt and hot and bothered me

however all seems to be going well in the world of the roll, except a couple of issues while ill mention later!

been to yet another show (japfest 2) at Donnington this weekend and was great show and the car went great on track, just i didnt do too well in the heat! didnt feel well all day, lack of sleep! far too hot in the hotel room and just uncomfortable and lets face it, cant beat your own bed!

heres me out on track with my gopro in the window as usual and doing well! just a shame i wasnt, i recorded 32°C on sunday and i had to have the windows only open an inch and legs and arms covered with my helmet on, far too bloody hot!

ill add some piccies later when i find them from the official photography and shamelessly steal them haha

also another vido from some randomer...

but before this i was having stopping issues, with them over heating and fading all the bloody time, which just isnt great when im getting into all this track malarky, so instead of making my brakes i have work well, i decided to upgrade and bloody hell that i have indeed done! they work spiffingly!

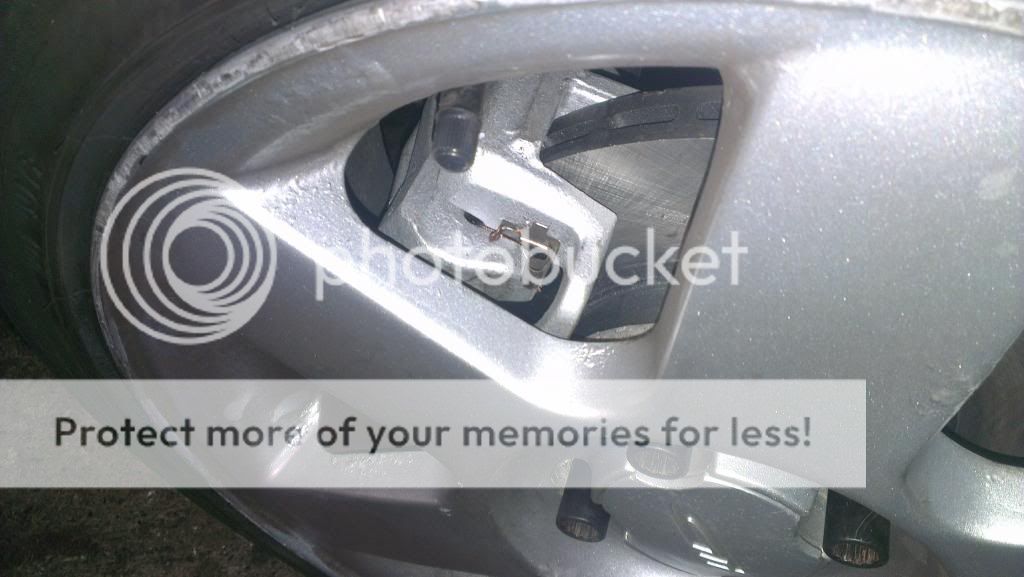

so i went about finding AE101 JDM (yo) brake s and after much faffing were in my hands with all the bits and bobs i require! result, so painted them silver (hammerite lol) and got them on, not after more faffing though!

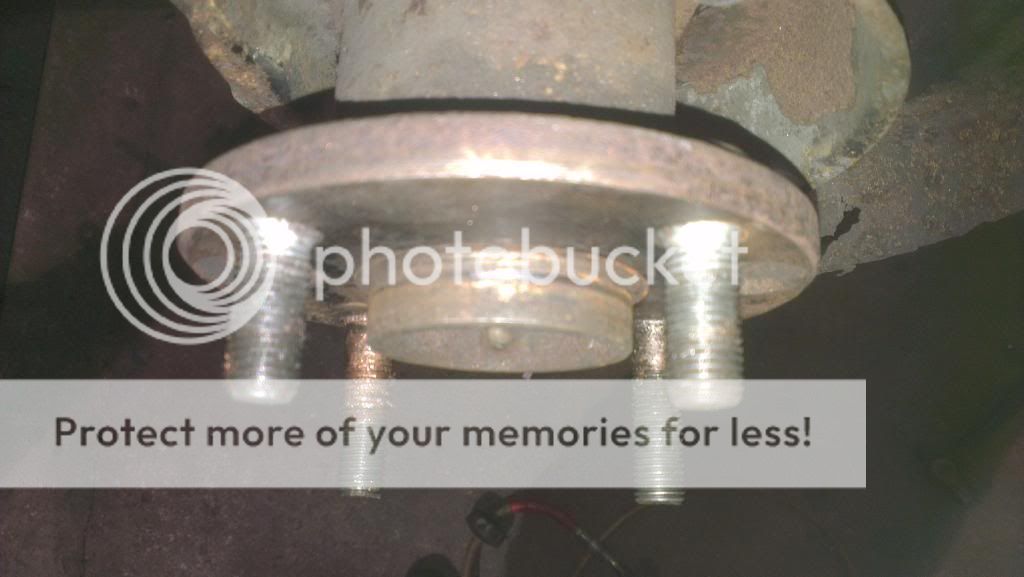

went to the local auto factors to see if they could match up the disk, to make life easier than using the st185 disk but to no avail and ended up with a later corolla disk but the disk height was much greater and if i were to space the disk out it wouldnt have been great, after getting a spcaer made id have to use longer wheel studs and would still have to have them machined from 277mm down to 262mm.

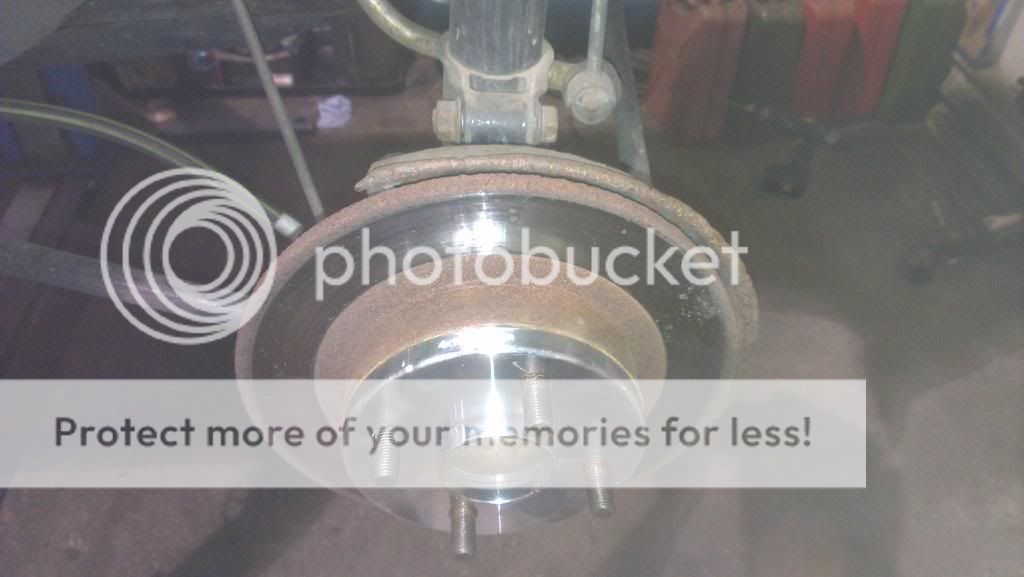

so after all that went out and got the 4x4 celica Gt-four disks and without checking them got them down the machinists to have them saved fown from 277mm to 262mm and then redrilled them from 5 stud to the required 4x100 stud pattern using a spare rear hub i have as a guide... see below!

however as upgrades go they are certinately worth it usually my brakes cook after 3-4 laps at donnington but this time lated 12 or so laps and thats when the timer ran out but could have given that again, however going to save up for some good pads to works with my disks! carbotechs FTW!

comparisson of old vs new before being machined down

jig made up to get the holes lined up to redrill the new disks, the 5 stud pattern lines up with one hole, so spare hub and all bar 3 studs kocked out provides the best jig going, as the centre bore is right!

old tiny brakes

new brakes fitted together

the wheel clearances

enjoy, more to come

however all seems to be going well in the world of the roll, except a couple of issues while ill mention later!

been to yet another show (japfest 2) at Donnington this weekend and was great show and the car went great on track, just i didnt do too well in the heat! didnt feel well all day, lack of sleep! far too hot in the hotel room and just uncomfortable and lets face it, cant beat your own bed!

heres me out on track with my gopro in the window as usual and doing well! just a shame i wasnt, i recorded 32°C on sunday and i had to have the windows only open an inch and legs and arms covered with my helmet on, far too bloody hot!

ill add some piccies later when i find them from the official photography and shamelessly steal them haha

also another vido from some randomer...

but before this i was having stopping issues, with them over heating and fading all the bloody time, which just isnt great when im getting into all this track malarky, so instead of making my brakes i have work well, i decided to upgrade and bloody hell that i have indeed done! they work spiffingly!

so i went about finding AE101 JDM (yo) brake s and after much faffing were in my hands with all the bits and bobs i require! result, so painted them silver (hammerite lol) and got them on, not after more faffing though!

went to the local auto factors to see if they could match up the disk, to make life easier than using the st185 disk but to no avail and ended up with a later corolla disk but the disk height was much greater and if i were to space the disk out it wouldnt have been great, after getting a spcaer made id have to use longer wheel studs and would still have to have them machined from 277mm down to 262mm.

so after all that went out and got the 4x4 celica Gt-four disks and without checking them got them down the machinists to have them saved fown from 277mm to 262mm and then redrilled them from 5 stud to the required 4x100 stud pattern using a spare rear hub i have as a guide... see below!

however as upgrades go they are certinately worth it usually my brakes cook after 3-4 laps at donnington but this time lated 12 or so laps and thats when the timer ran out but could have given that again, however going to save up for some good pads to works with my disks! carbotechs FTW!

comparisson of old vs new before being machined down

jig made up to get the holes lined up to redrill the new disks, the 5 stud pattern lines up with one hole, so spare hub and all bar 3 studs kocked out provides the best jig going, as the centre bore is right!

old tiny brakes

new brakes fitted together

the wheel clearances

enjoy, more to come

well, whats going on in the world of will

i went to yet another show! and on track yet again after the fail of japfest aha

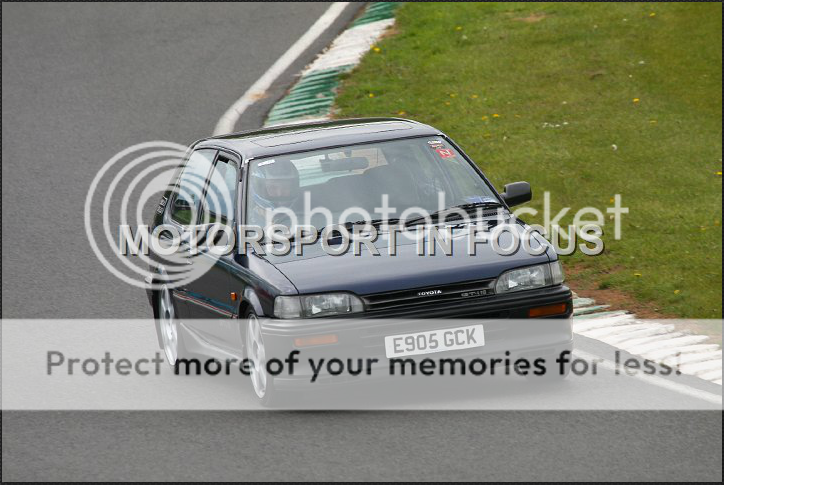

this time it was at mallory park for practical performance car mag, started off as a dreary cold and windy day with LOTS of rain forcast which happily never came, and it didnt kind of warm up but no sun!

the track was great and much faster than lydden hill, with the chicane not being used it was rather mental knocking on the door of 100mph!

so enough babble heres the video

and some shamefully stolen official pics!

still echoing the need for brakes and some anti roll oh and POWERRRRRRRRRRR

just wish i had more gahoonies into gerrards but every lap slowed too much but each time exited faster lol

luckily for me and my back the normal seat is back in for now so comfort

i went to yet another show! and on track yet again after the fail of japfest aha

this time it was at mallory park for practical performance car mag, started off as a dreary cold and windy day with LOTS of rain forcast which happily never came, and it didnt kind of warm up but no sun!

the track was great and much faster than lydden hill, with the chicane not being used it was rather mental knocking on the door of 100mph!

so enough babble heres the video

and some shamefully stolen official pics!

still echoing the need for brakes and some anti roll oh and POWERRRRRRRRRRR

just wish i had more gahoonies into gerrards but every lap slowed too much but each time exited faster lol

luckily for me and my back the normal seat is back in for now so comfort

@Jen319 i know you havent read this, or if you have thank you  but judging by what ive seen your by far the best at photochopping do you mind having a go as making my bumpers, skirts and spoiler body colour? using a couple of pics from this thread, and if you fancy one or two with metalic black bumpers hehe

but judging by what ive seen your by far the best at photochopping do you mind having a go as making my bumpers, skirts and spoiler body colour? using a couple of pics from this thread, and if you fancy one or two with metalic black bumpers hehe

thank you muchly, i keep trying but instead changing everything

thank you muchly, i keep trying but instead changing everything

@Jen319 i know you havent read this, or if you have thank youbut judging by what ive seen your by far the best at photochopping do you mind having a go as making my bumpers, skirts and spoiler body colour? using a couple of pics from this thread, and if you fancy one or two with metalic black bumpers hehe

thank you muchly, i keep trying but instead changing everything

I'll give it a go

I'll give metalic black a try too, might be a bit tricky, I should be able to body colour the skirts and bumpers easy enough though

thank youif you can do one showing the red pin stripe that would be great, however dont worry as i can picture it looking terrible!

this is what I got... body colour....

The black didn't really....work... metallic wise

I'll re-draw in the pinstripe in another body colour one for ya in a mo

Should do it the AE86 Colour scheme will!!!

thats what i was thinking with using the black, but i think body colour is the way to go, however as i found its not so easy to make it look natural

great effort though @Jen319

@Jen319

Quickly do AE86 Colours?...

I can probably do it, but it ain't gonna be quick LOL

I've re-painted your pin-stripe

I feel I must urge you to do this LOL

the stripe makes it more, if that makes sense?

idea would be to body colour it all, and remove the bump strips and keep the pin stripe and GTi-16 vinyl!

i owe you a drink when you come to JAE ( see you you don't have a choice )

idea would be to body colour it all, and remove the bump strips and keep the pin stripe and GTi-16 vinyl!

i owe you a drink when you come to JAE ( see you you don't have a choice )

sounds like a plan...

I'm most likely not gonna be at JAE...

might....I stress Might, be next year

one AE86 style...yeah...not great I know....kinda tricky to keep any kind of shine in the paint when going from a dark colour to white

ETA: and I've screwed up the layered cut around the rear light *facepalm*

sounds like a plan...

I'm most likely not gonna be at JAE...

might....I stress Might, be next year

one AE86 style...yeah...not great I know....kinda tricky to keep any kind of shine in the paint when going from a dark colour to white

ETA: and I've screwed up the layered cut around the rear light *facepalm*

its alright close up toyota made the rear lights look like that!

however i dont think this scheme will work on it im afraid! i also want to keep the original blue because its rare

thanks again!

what is your excuse for not coming?

...thanks again!

what is your excuse for not coming?

You're welcome

well...I actually don't know, I'd really like to go...but...

no job?...dodgy paintwork?...mum wont let me go on my own...even though I'm 27! LOL

You're welcome

well...I actually don't know, I'd really like to go...but...

no job?...dodgy paintwork?...mum wont let me go on my own...even though I'm 27! LOL

i do not believe that is an excuse, lol you think your paint is bad take a look at mine varying shades of blue with laqure feel and fade lol

so update time,

well I was getting worried about the play in the steering as it felt dangerous imo, and I was dreading having to change the steering rack again, however when I looked under the dash just to confirm the rack I was surprised to find alot of play at where the UJ joins the column, so looking into it more there wasn't any space for adjustment, so i figured I'd simply zap it up with the mig! which wasn't so easy in the space under the dash, however it went well and the steering feels tight and amazing

so mega happy times...

so mega happy times...

then yesterday i set about changing my front lower rear arm bushes for the kind which increase the castor, which in turn keeps the wheels straightened while moving along, the faster your going the better it works, so on the motorway it will go straight all day long untill a bend simply appears, the only down side is that the P/S has to work a little harder....

new vs old, castor bush one thats off set....

and obviously retracked up the car which i done with my new gauge which is called trackace and it brilliant for someone to check etc, i found it much better than the dunlop gauqages we use at work!

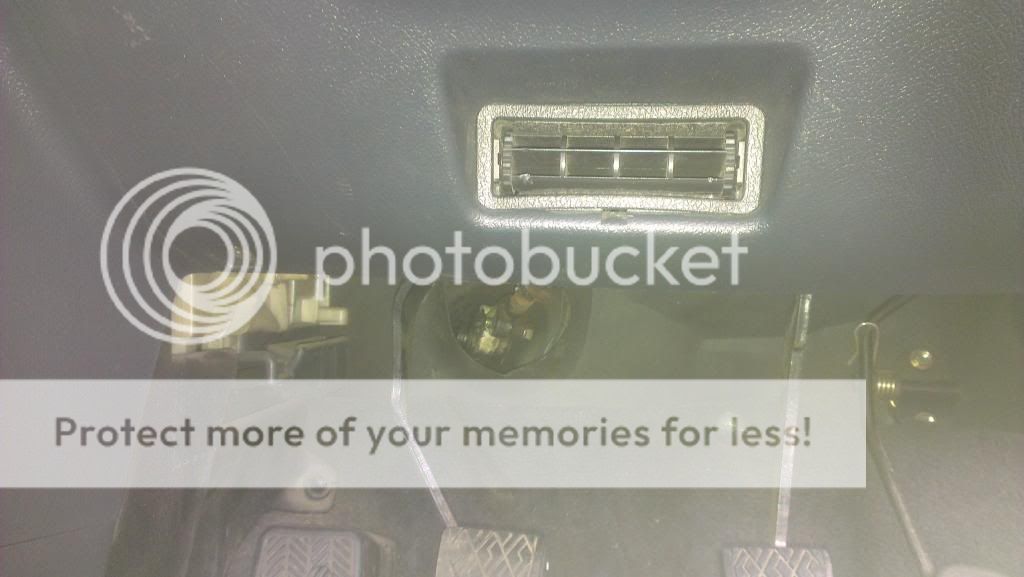

and finally today i fitted my cup holder from Peter which is great, been on the hunt for a suitable one to bodge in for ages!

also fitted the crotch vent, which isnt really needed but just one of those little things im sure ill like in the winter when im freezing my bollocks off! lol

more to come later, as im going to service and swap my new wheels on for now before being refubed as they have decent tyres!

well I was getting worried about the play in the steering as it felt dangerous imo, and I was dreading having to change the steering rack again, however when I looked under the dash just to confirm the rack I was surprised to find alot of play at where the UJ joins the column, so looking into it more there wasn't any space for adjustment, so i figured I'd simply zap it up with the mig! which wasn't so easy in the space under the dash, however it went well and the steering feels tight and amazing

then yesterday i set about changing my front lower rear arm bushes for the kind which increase the castor, which in turn keeps the wheels straightened while moving along, the faster your going the better it works, so on the motorway it will go straight all day long untill a bend simply appears, the only down side is that the P/S has to work a little harder....

new vs old, castor bush one thats off set....

and obviously retracked up the car which i done with my new gauge which is called trackace and it brilliant for someone to check etc, i found it much better than the dunlop gauqages we use at work!

and finally today i fitted my cup holder from Peter which is great, been on the hunt for a suitable one to bodge in for ages!

also fitted the crotch vent, which isnt really needed but just one of those little things im sure ill like in the winter when im freezing my bollocks off! lol

more to come later, as im going to service and swap my new wheels on for now before being refubed as they have decent tyres!

James

Chairman

also fitted the crotch vent!

More cars need this vent... What an excellent idea.

Enuo

Glorified Electrician

I'll look after you, I'm well qualified for the job!You're welcome

well...I actually don't know, I'd really like to go...but...

no job?...dodgy paintwork?...mum wont let me go on my own...even though I'm 27! LOL

Just found this thread, met you at my first ever Micra meet in reading and never been able to put a username to a face 'til now, only took like 7 months! Looking good still

More cars need this vent... What an excellent idea.

yeah was only an optional extra in the US so i got one

...and just to add, I've caught up on this thread now from when I last saw it (taken me about 30-40 mins). Great work Will, this car a testament to you! I look forward to seeing it at JAE

hope you dont feel it was a waste of time

Right let's kick things off, I haven't done any updates for so long now I have a ton of pictures and let's to catch up on!

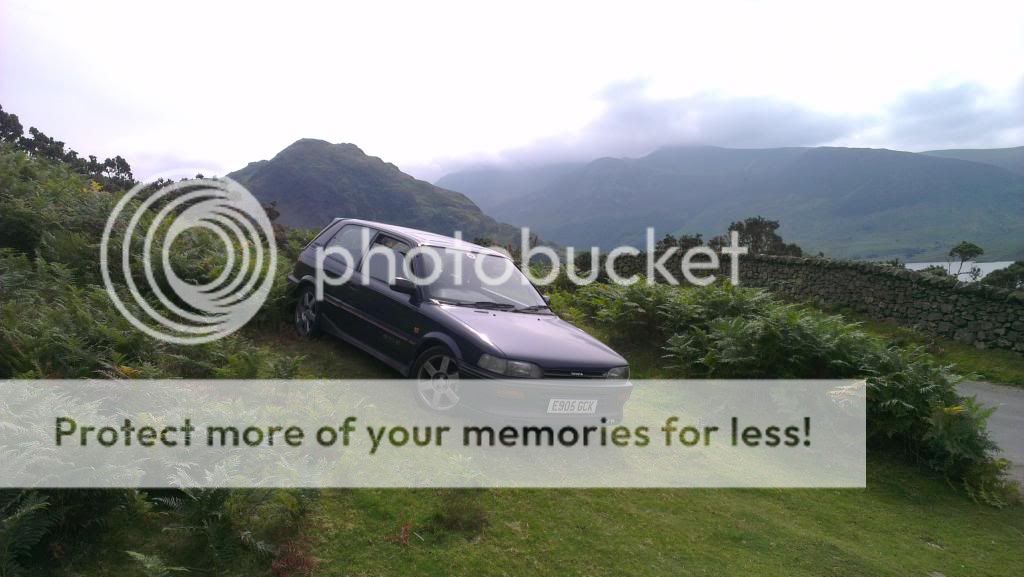

So let's look back to last summer when I was on my holidays in he lake district enjoying the roads and other stuff so have some arty rubbish pics of the old girl!

right enough of that so to roll on to August some time hard to remember! Lol the wheels in the above pics were failing on me with 3 of them buckled and just didn't look great so got on the hunt for some new ones, my choice may be contraversal however I like them and they're good wheels! However at the rear they were catching the rear shock so had to fit spacers and longer studs!

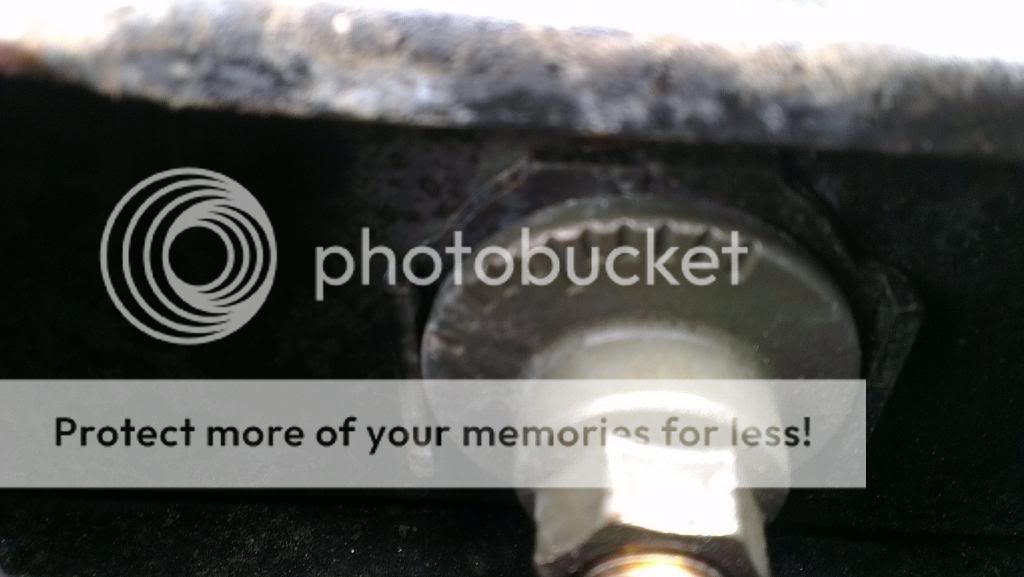

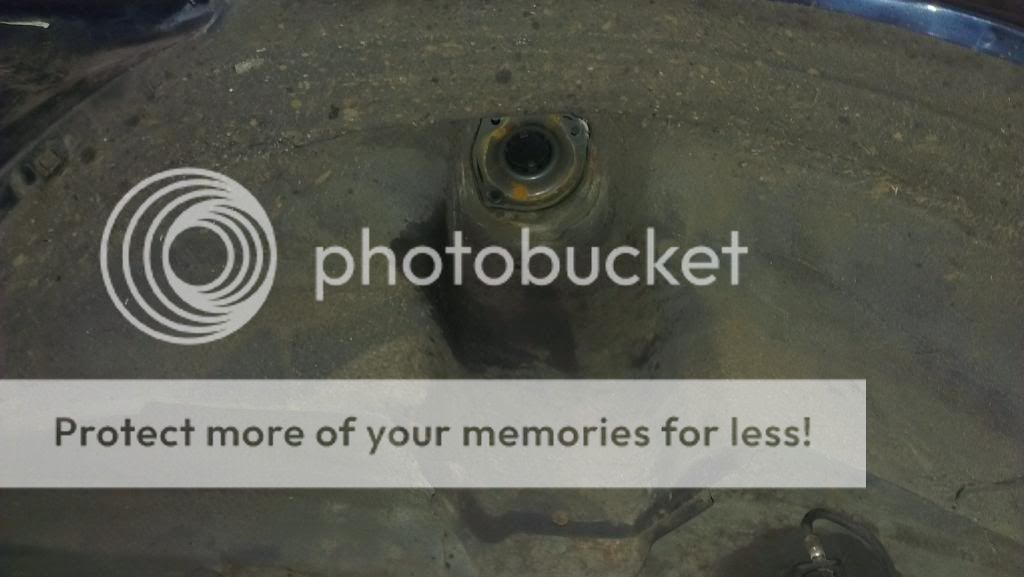

Which involves banging out the rears and pulling in new ones like so

they're 13 mm longer which is plenty long enough!

the method of refitting! I think I had to die grind the holes slightly as they were far too tight for me to get them in!

so now the studs are done time for the spacers! Didn't want them dodgy halfords specials and I managed to fine 13 mm hubcentric spacers from an me which share the same stud pattern and centre bore as our dear corolla

and there we have it the new wheels fitted and a picture from the return from the tyre shop to have the tyres swapped from the old wheels!

however as nothing is ever easy in the car world, yes I had spaced the rear wheels out but now they were car hinge the rear arches and with no option to get back a fit a smaller spacer I trooped on and done this!

I much prefer this to rolling! Essentially cut lots of little slits into the arch and wire brush all the crap from behind fill it with tiger seal and fold all the tabs back then using more tiger seal smooth it all over so that it cannot rust and no sharp edges! That sorted it for me luckily .

.

Moving onto JAE weekend I only took a couple of pics the entire time lol.

After that the corolla came off the road for winter which I wish I didn't do as winter was good with virtually no salt being used. However not knowing that I done it anyway! Lol but I did do a couple of other bits during that time like look at fitting an epas steering column from a corsa c for remove the hydraulic unit but after complications s of it fitting and more reading saying less feel etc I gave up on that idea...

and the only other job I had to do before MOT was change a c boot which had started to let go before it came off the road leaving crap over my white wheels!

hate doing them such a messy job it gets everywhere that grease!

Right that's it for now more soon!

So let's look back to last summer when I was on my holidays in he lake district enjoying the roads and other stuff so have some arty rubbish pics of the old girl!

right enough of that so to roll on to August some time hard to remember! Lol the wheels in the above pics were failing on me with 3 of them buckled and just didn't look great so got on the hunt for some new ones, my choice may be contraversal however I like them and they're good wheels! However at the rear they were catching the rear shock so had to fit spacers and longer studs!

Which involves banging out the rears and pulling in new ones like so

they're 13 mm longer which is plenty long enough!

the method of refitting! I think I had to die grind the holes slightly as they were far too tight for me to get them in!

so now the studs are done time for the spacers! Didn't want them dodgy halfords specials and I managed to fine 13 mm hubcentric spacers from an me which share the same stud pattern and centre bore as our dear corolla

and there we have it the new wheels fitted and a picture from the return from the tyre shop to have the tyres swapped from the old wheels!

however as nothing is ever easy in the car world, yes I had spaced the rear wheels out but now they were car hinge the rear arches and with no option to get back a fit a smaller spacer I trooped on and done this!

I much prefer this to rolling! Essentially cut lots of little slits into the arch and wire brush all the crap from behind fill it with tiger seal and fold all the tabs back then using more tiger seal smooth it all over so that it cannot rust and no sharp edges! That sorted it for me luckily

Moving onto JAE weekend I only took a couple of pics the entire time lol.

After that the corolla came off the road for winter which I wish I didn't do as winter was good with virtually no salt being used. However not knowing that I done it anyway! Lol but I did do a couple of other bits during that time like look at fitting an epas steering column from a corsa c for remove the hydraulic unit but after complications s of it fitting and more reading saying less feel etc I gave up on that idea...

and the only other job I had to do before MOT was change a c boot which had started to let go before it came off the road leaving crap over my white wheels!

hate doing them such a messy job it gets everywhere that grease!

Right that's it for now more soon!

A delayed part 2! Im pretty rubbish at this updating malarky arent i? Haha owell in this part i shall cover the roof repaint section which happened just after i returned the car to the road!

So firstly the old screen was removed

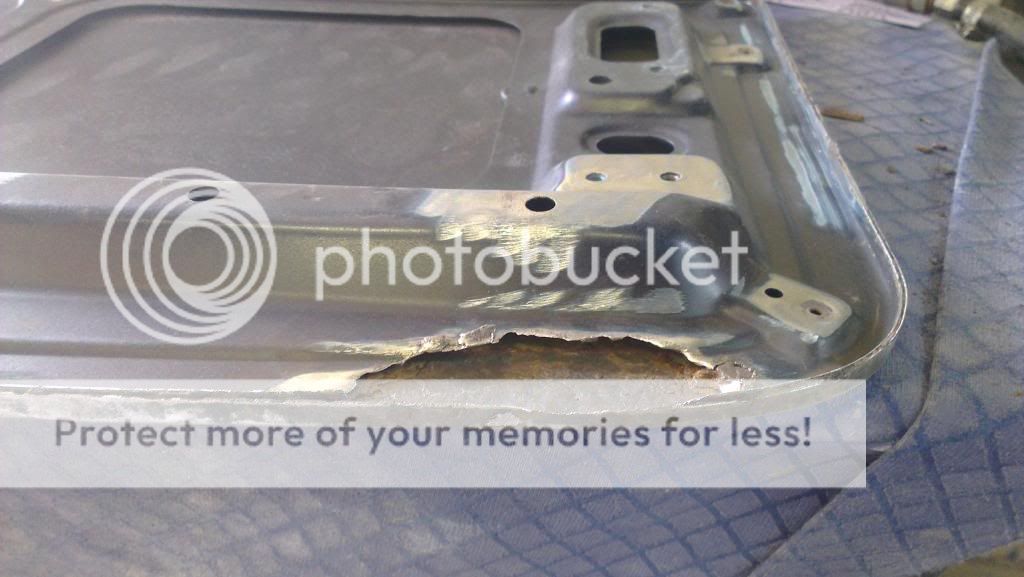

The main reason the screen was removed was this rust around the top edge of the screen which you may remember i tried to tackle a couple of years ago but was difficult with the screen in place!

The other side wasnt too bad just a small hole, any hole is bad enough, these holes all got plugged with weld to keep them going for aother few years

The roof lookig all dotty and covered in stone chips and small dents so stoppered them all up!

Onto the sun roof and it had gone badly in two places which wa pretty bad this is once cleaned up

And the other side

And the top edge to give an example and the pin holes left in the metal im suprised it didnt leak to be honest!

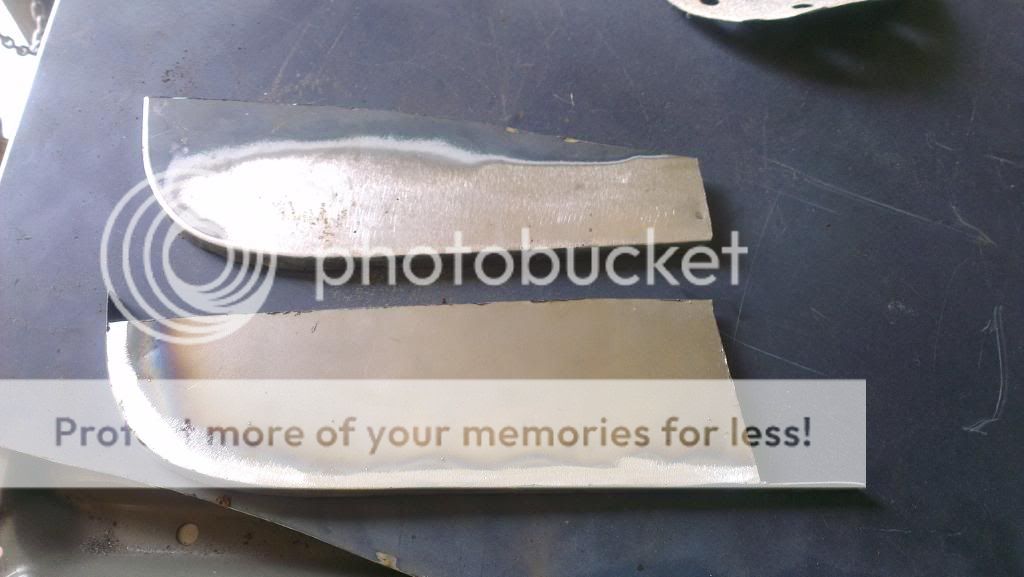

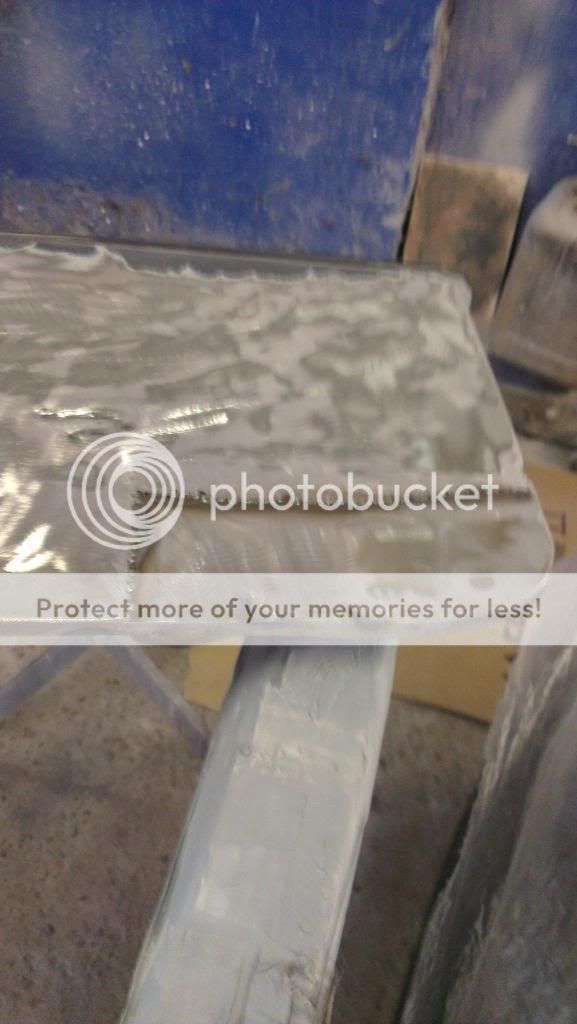

The starts of a repair section, id make the top and sides first and while still clamped id weld the two together to keep the shape like so

D section cut out but i made a booboo here and cut out a section bigger than my repair section lol

Old vs new

Fibreglass added to the windowscreen areaso make the shape better and more accurate on both sides and an extra layer of protection for the metal too!

The repair section for the other side of the sunroof probably would have been better to make it one large section across the front but didnt want to take on more than i could chew! Lol

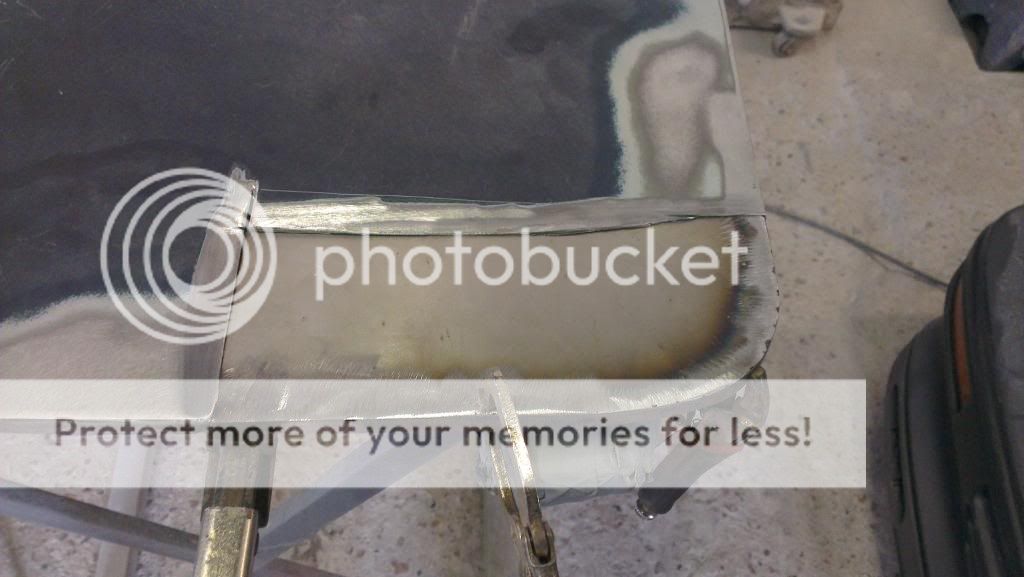

Clamped in and ready for welding!

And all welded in ready for coupious amounts of filler as i madea balls up and got it too hot annoyingly

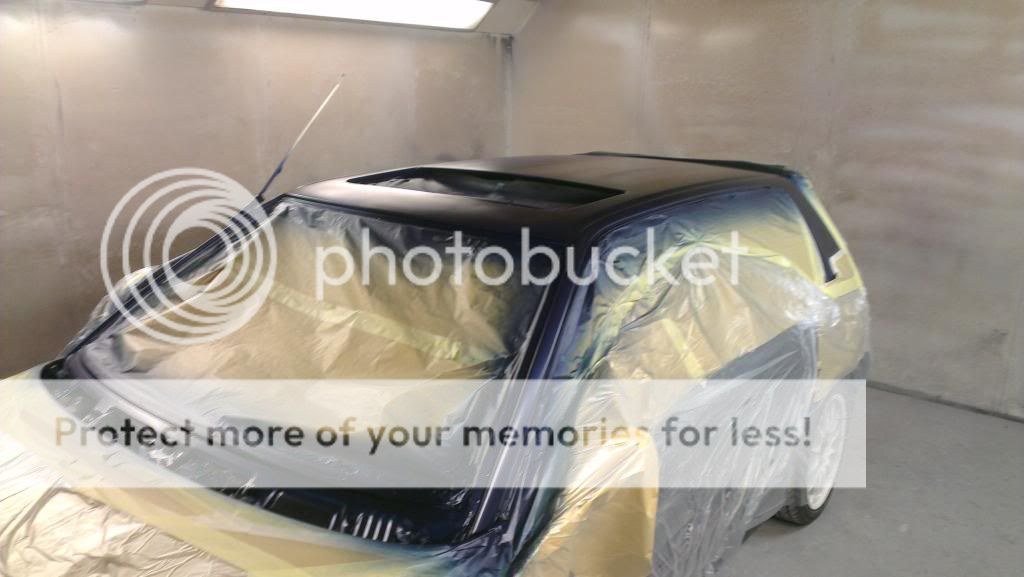

All masked and first coat of primer applied

All flatted and ready to go into the over getting excited now

Sunroof test fitted before paint and it fits still whoop

As opposed to making an inner section i just smudged in some seam sealer as it makes no difference to its operation and the amount of time taken on the panel i was getting fed up lol

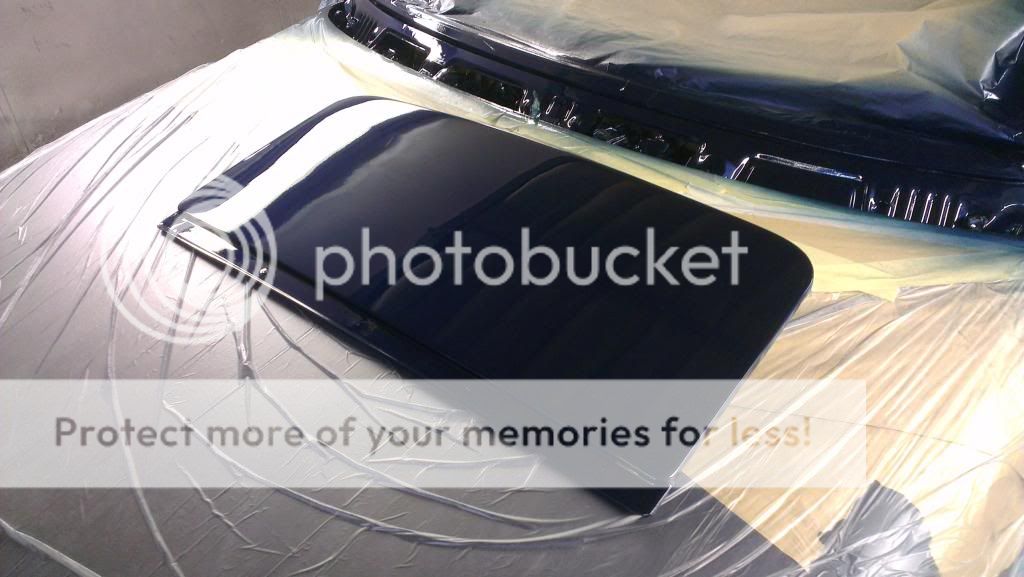

Paint going on!

Inside of the sunroof panel painted in matt black, with all the areas under the support waxoyled alot and left over night before flipping the right way up! And the rubber around the edge was put on with a small amount of stikaflex on the rubber to stop water pooling in the bottom and rusting up the edge of the sunroof

Once it was all fitted up a day before the window screen was due to be fitted ense of relief was felt untill the day came and nobody turned up fr me to eventually get through the the copany (Auto Windowscreen) for them to tell me they cant get the screen in at all????? And this is a day after they were due to come all with messages on the run up confirming the apointment and time etc.... so in an emergency i phoned up another company who came out that saturday morning to fit a new one? Stupid people! However eventually got through to my insuance company who refunded me everything so i got a free window screen whoop! Lol

So firstly the old screen was removed

The main reason the screen was removed was this rust around the top edge of the screen which you may remember i tried to tackle a couple of years ago but was difficult with the screen in place!

The other side wasnt too bad just a small hole, any hole is bad enough, these holes all got plugged with weld to keep them going for aother few years

The roof lookig all dotty and covered in stone chips and small dents so stoppered them all up!

Onto the sun roof and it had gone badly in two places which wa pretty bad this is once cleaned up

And the other side

And the top edge to give an example and the pin holes left in the metal im suprised it didnt leak to be honest!

The starts of a repair section, id make the top and sides first and while still clamped id weld the two together to keep the shape like so

D section cut out but i made a booboo here and cut out a section bigger than my repair section lol

Old vs new

Fibreglass added to the windowscreen areaso make the shape better and more accurate on both sides and an extra layer of protection for the metal too!

The repair section for the other side of the sunroof probably would have been better to make it one large section across the front but didnt want to take on more than i could chew! Lol

Clamped in and ready for welding!

And all welded in ready for coupious amounts of filler as i madea balls up and got it too hot annoyingly

All masked and first coat of primer applied

All flatted and ready to go into the over getting excited now

Sunroof test fitted before paint and it fits still whoop

As opposed to making an inner section i just smudged in some seam sealer as it makes no difference to its operation and the amount of time taken on the panel i was getting fed up lol

Paint going on!

Inside of the sunroof panel painted in matt black, with all the areas under the support waxoyled alot and left over night before flipping the right way up! And the rubber around the edge was put on with a small amount of stikaflex on the rubber to stop water pooling in the bottom and rusting up the edge of the sunroof

Once it was all fitted up a day before the window screen was due to be fitted ense of relief was felt untill the day came and nobody turned up fr me to eventually get through the the copany (Auto Windowscreen) for them to tell me they cant get the screen in at all????? And this is a day after they were due to come all with messages on the run up confirming the apointment and time etc.... so in an emergency i phoned up another company who came out that saturday morning to fit a new one? Stupid people! However eventually got through to my insuance company who refunded me everything so i got a free window screen whoop! Lol

Similar threads

- Replies

- 40

- Views

- 4K

- Replies

- 0

- Views

- 740