im sure it says has to be original seat,? i may be wrong?

Just fold them, as long as the are left in it doesn't matter what position they are in

im sure it says has to be original seat,? i may be wrong?

Just fold them, as long as the are left in it doesn't matter what position they are in

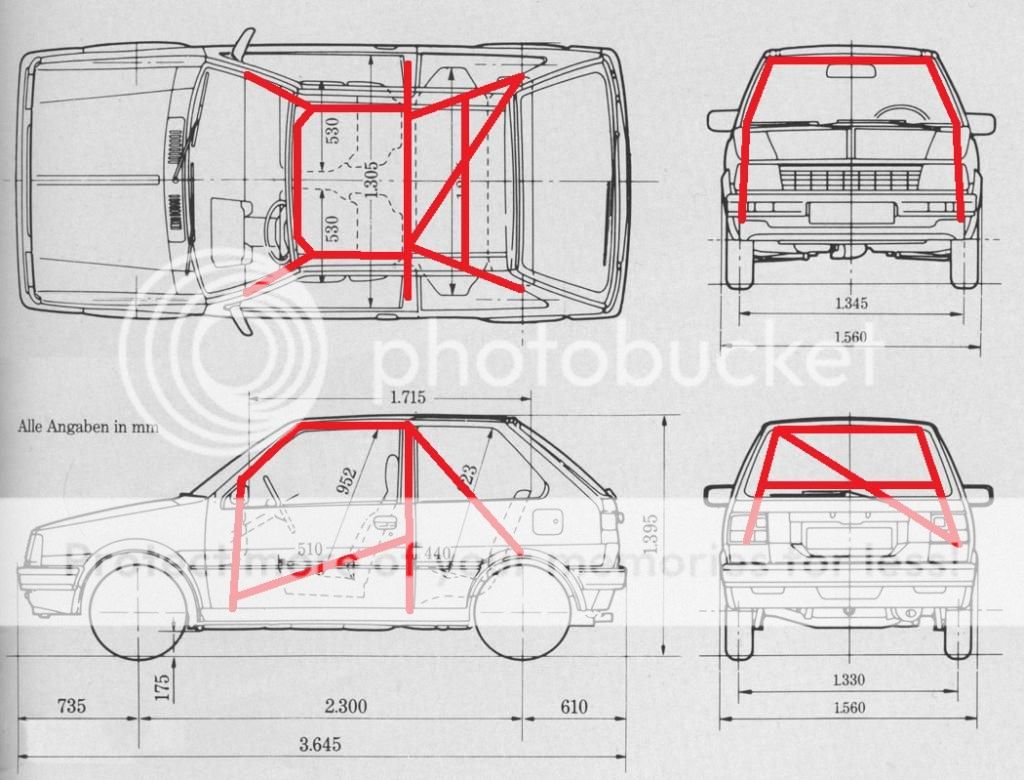

Iirc its £30 for 6 metres... and I believe a 6 point is approx 8 metres... door bars are 2 metres a set and the rear x with harness is another 4metres....

If you flick back through this thread I've got it all down

The more notice I have the betterworks out at about 16 meters so go for 18 metres if its £30 for 6 meters

18 meters = £90

fitting = £150?

around £250 not badhow much notice you need t o get the materials?

That's a good question. It depends what material you choose tooJust wondering how much weight the roll cage would add? Do you know?

Of course a pair of bucket seats and harnesses would also suitYeah I would strip the back seat out and other bits n pieces in-order to have a roll cage anyway. Would look loads better

V6?Defo. Got it all planned out. Just need the engine to suit the style I'm going for lol

MA10?... ask @belly93 my MA10 is a very capable engineI was just thinking my 1L isn't going to hold that weight lol

i could do but ideally i wouldnt mind stripping and replacing shells and seals aswell as get the head skimmed to raise the comp aswell as have it ported,Or just bike carb mineunless that's what you meant :/

Doooo itttti could do but ideally i wouldnt mind stripping and replacing shells and seals aswell as get the head skimmed to raise the comp aswell as have it ported,

Only bolt in ones I've seen are show cages, welded is always better for safety.Something I've been thinking about as well. What would be better to have, a bolt in cage or welded in cage? I seem more strength from the welded one but if you need it out at all then you got to cut it out? But a welded one looks nice and smooth without a tonne of bolts poking out. Any ideas what would be best?

Something I've been thinking about as well. What would be better to have, a bolt in cage or welded in cage? I seem more strength from the welded one but if you need it out at all then you got to cut it out? But a welded one looks nice and smooth without a tonne of bolts poking out. Any ideas what would be best?

I've seen show cages steel are made of 4" x 1mm steel tubing... pathetic and stupid they're a hazard. Welded in proper cages are always the way forwardOnly bolt in ones I've seen are show cages, welded is always better for safety.

I've seen show cages steel are made of 4" x 1mm steel tubing... pathetic and stupid they're a hazard. Welded in proper cages are always the way forward

However so long as your 6 point is welded and the harness bar welded then the rest can be bolt in. My door X bars may be bolt in as its also a daily. Correctly done a bolt in is effective but does take more time

That's fair enoughbit of box section will get ypur seats in no problem

Certainly isIs that something you could help out with as well??

Game on?Hey Andy its been awhile but its finally time for me to think about that cage. I've notice I get a bit of chassis twist maybe from how stiff the coilovers are (interior light keeps turning on around corner etc) and I think its time the chassis could do with some stiffening. What do you say?

I know it's roughly a 4 hour trip to yours, so I need to plan this. I also need to plan money. Is this something you think you could finish over a weekend? Also keep it in mind I have no idea what material is required or where to get it lol.Game on?

I'll look into it for youHaven't got around to phoning insurance just yet. What would your price range be for that kinda set up?

You need to send a weld sample to be tested for yield strength.Im going to weld a cage into mine just wondering if it'll be acceptable for FIA rallies, how do you get it legal? I understand it must be built to MSA regs thickness angles etc but after it's built do you need someone to come out and deem it "safe" Or is that what scrutiny is for? Thanks

Some scrutineers ask for a certificate of conformity form a yield test.Do you need it to be FIA spec? Unless you plan to build a Grp N/A car for overseas events, the cage 'just' needs to be made to the specs in the MSA Blue book and as per their diagrams. The test weld bits and bits of paper are for some cage companies. No need for a certificate to get a MSA Log book. Our cage was bespoke made to our spec, by a local (at the time) guy who did it to MSA spec and a good quality, no certificates etc... and no issues getting a log book.

Our bespoke weld in cage fully fitted (with no paint) was less than buying the Custom Cages kit.....