-

Please only use these forums for blogs, they are not a discussion forum

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Porks bike carbs and boost project

- Thread starter pork

- Start date

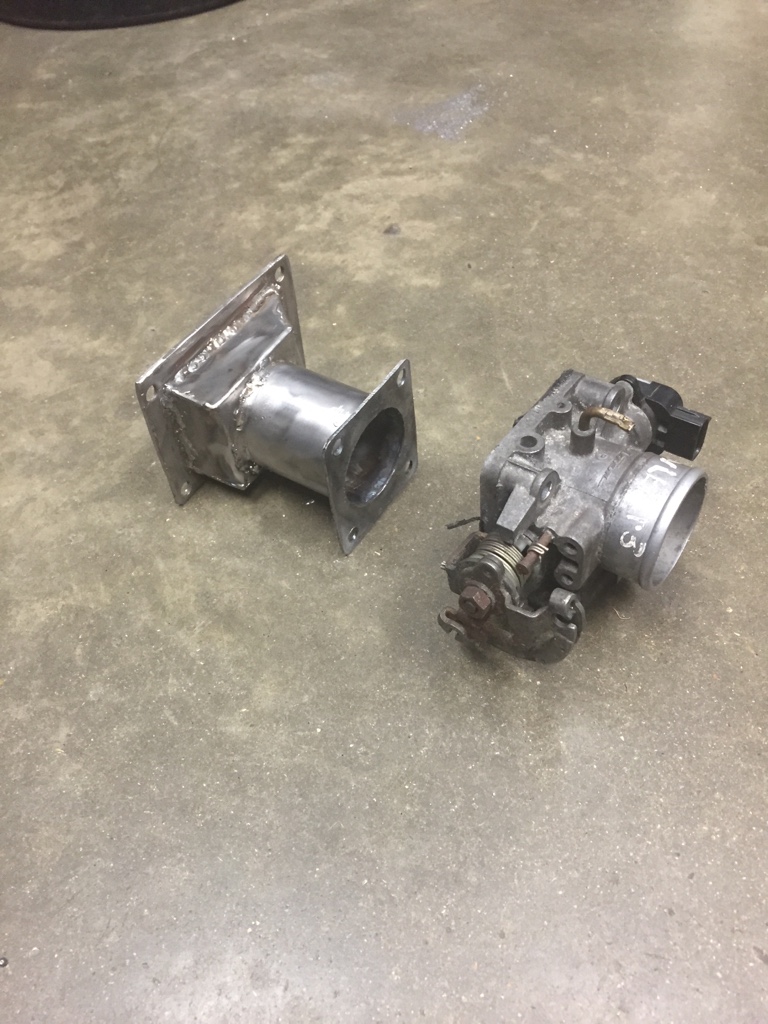

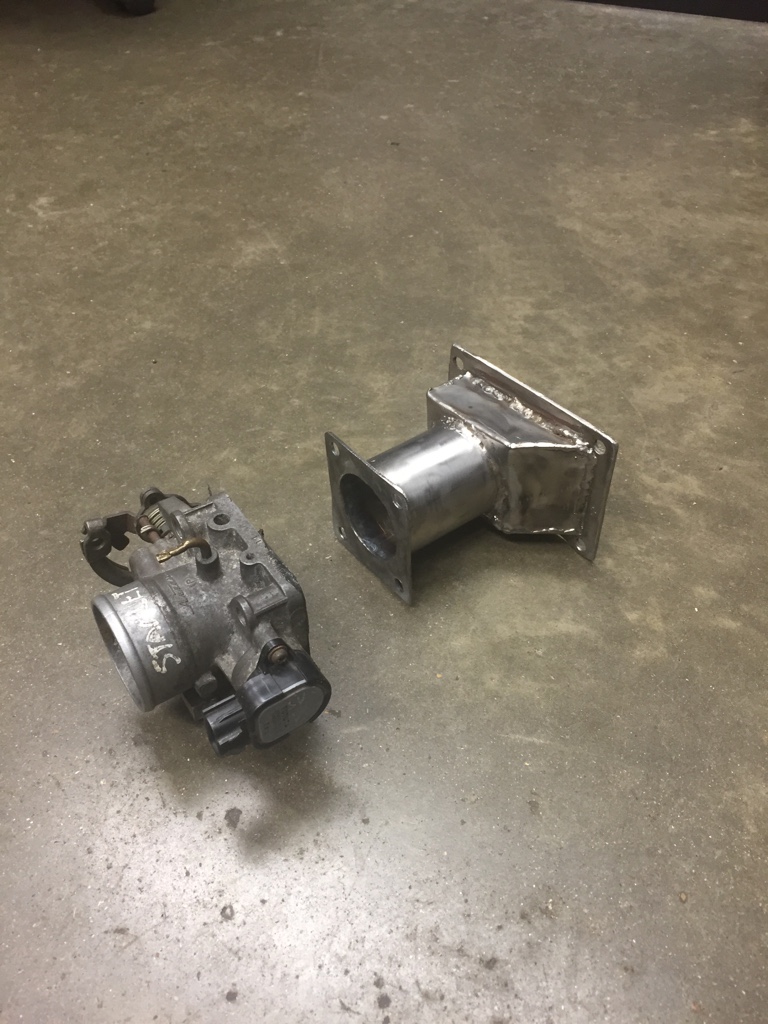

If you change the TB let me know as I still can't find mine

Do you need a stock k11 tb?

Ah okay, might still be interested thoughYou wouldn't want it mate, I crushed of a few pipes and blanked some other idle stuff, just basically a butterfly valve and that's it

Sent from my iPhone using Tapatalk

best for MIG is argon + co2

and TIG its only argon, on MIG the misture with 2 gas (argon+co2) because argon are more expensive, this is what we usually use where I work , now do not know what percentage of each in the bottle

frank

Club Member

get the stick welder out neilBit of work done on the inlet.....ran outa gas

Sent from my iPhone using Tapatalk

Attachments

frank

Club Member

nah, welding is not my forte neil, those stainless rods flow really niceYeah, but you have mad skills

Sent from my iPhone using Tapatalk

frank

Club Member

arc penetrates better imo edIv done a bit of DC stick welding lately. its a breeze, better than MIG imo unless you are doing <1mm. That SS stuff looks very nice Frank, did you get any warping of the flanges?

neil will be doing some stainless welding on his kit-form mani too (when i can find his postal addy

Almost impossible to stop SS warping unless you bolt it down to a jig iv found.arc penetrates better imo edand yes the flanges did curl their toes a bit as you can see, but luckily its in the right direction for squashing the gasket when the nuts are pulled down

neil will be doing some stainless welding on his kit-form mani too (when i can find his postal addy)

View attachment 40168

h701micra

Deactivated Account

If you can get yourself a chunky aluminium plate or brass plate. It'll soak the heat away before warping can occurAlmost impossible to stop SS warping unless you bolt it down to a jig iv found.

news?

pork

Club Member

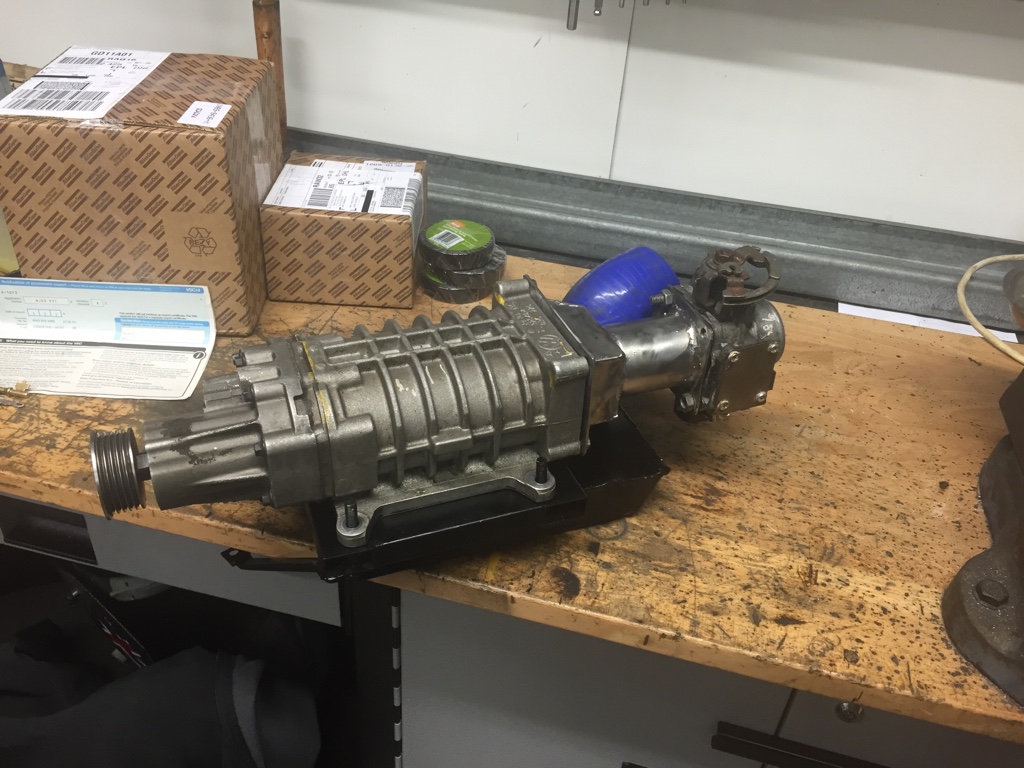

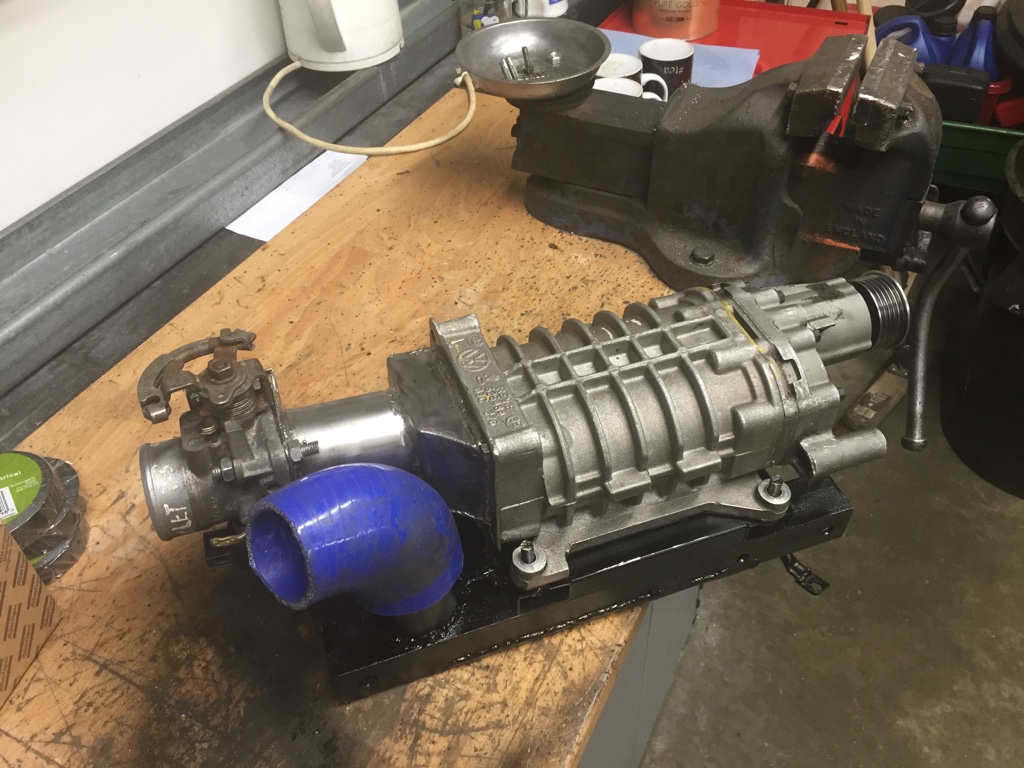

Had a start on welding the manifold up,

I leafy the flanges quite big so it didn't warp, il grind them down later

Never welded stainless before, not toooo bad

Quick look of how things will look.....will be putting charge cooler between charger and inlet

Sent from my iPhone using Tapatalk

I leafy the flanges quite big so it didn't warp, il grind them down later

Never welded stainless before, not toooo bad

Quick look of how things will look.....will be putting charge cooler between charger and inlet

Sent from my iPhone using Tapatalk

I wish mate, yours is super clean

I literally hav no money (house consumes all)

Mot has ran out now

pork

Club Member

I thought you were selling up for a flat dude

I was selling my flat for a house

Now have house, and done all major renovations, (kitchen, bathroom, phoebes room)

I've got a man shed now too

No one bought all my engine stuff, so all I need is a rolling shell and bolt all this stuff that's sitting here doing nothing in

Sent from my iPhone using Tapatalk