You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

need info re front wishbone - balljoints

- Thread starter funky2nite

- Start date

I replaced all my bolts with stainless steel bolts

You'll want M12 x 70

If you turn the bolt you'll hear the insert turning inside the rubber

They've either rusted together or the bolt itself has bent

Too right, all replaced with A4-80 and SS bush casings where possible too. Grinding everything out is only something you want to have to do once

h701micra

Deactivated Account

The stress my axle caused me... never againToo right, all replaced with A4-80 and SS bush casings where possible too. Grinding everything out is only something you want to have to do once

Stainless all round now

funky2nite

Ex. Club Member

sorry to hijack and bring back up, but I'm doing the same job today with difficullty i can't even budge the bolt holding the wishbone in as in video. I was hoping to drop it all down with the a/r/b still attached then same on the grasser, if i do it this way can i just grind the nuts off if can get to it and replace with new ones? not to sure how they look when come out

Cheers

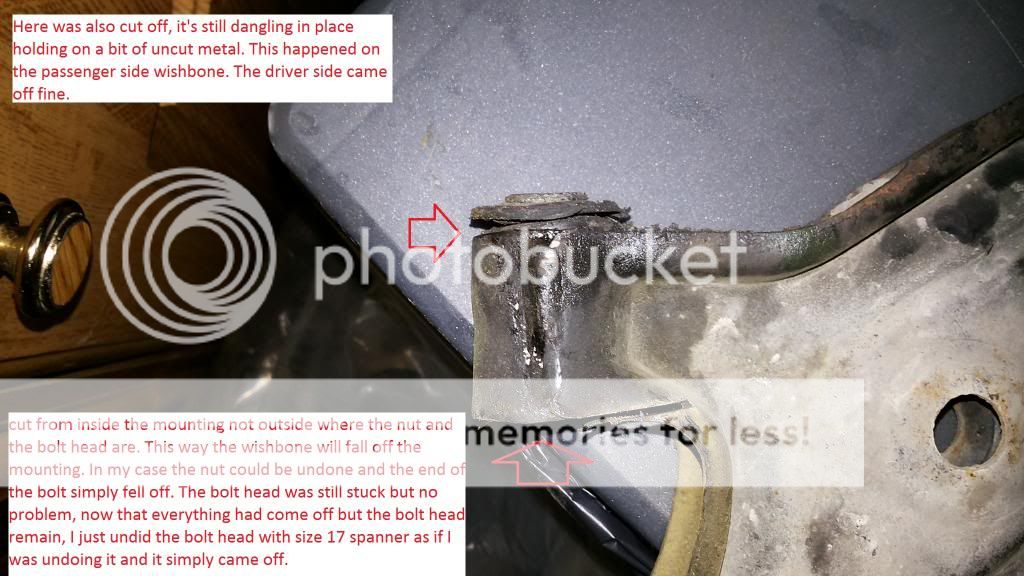

eyy man sorry for taking long to reply. No worries abt hijacking anything. Just did mine yesterday, turned out piece of cake. I've taken some photos to show from where we had to grind the bolt that was fused inside the bush. BTW this only happened on the passenger side thankfully

bolts I bought stainless steel 12 body thickness and 70mm length, but the ones I found had all the bolt's body threaded and I worried that the bush would be damaged resting on a threaded surface. So I got galvanised ones which had half the bolt's body smooth and the rest threaded also 70mm and got new nuts with nylon the new sort of nut nowadays.

fused bolt inside wishbone

Cut off bolt from inside of the mounting

Cut off both sides of the wishbone mounting without damaging the mounting on the car since the new one must fit in place

The ball joint seen below in the vid

h701micra

Deactivated Account

It'll be a case of new bushes mategrrrr so what would you do grind the head off and the bolt and prise away from car then get the bolt out or will it still not come out once i have done that

h701micra

Deactivated Account

I got mine from eBay. Half threaded bolts and nyloc nutsahh cheers for that bud where you get replacement bolts from

ohh man thought it would be a straight swap with a new bolt grrrrIt'll be a case of new bushes mate

h701micra

Deactivated Account

Fraid notohh man thought it would be a straight swap with a new bolt grrrr

I made some nylon ones for my wishbones. As I don't know if they're replaceable but I'd rather stiffer ones anyway

If i buy a new one i have plenty of time but need to get rid of this donor car ASAP

I will be test fitting my polyurethane bushes tomorrow

Front and rear bushes for both wishbones should end up around £30 posted. May work out a better option?

h701micra

Deactivated Account

Exactly what I would have suggestedI will be test fitting my polyurethane bushes tomorrowIf they work I will be making some to sell through nodspeed.

Front and rear bushes for both wishbones should end up around £30 posted. May work out a better option?

funky2nite

Ex. Club Member

Good to see it's been a contribute to others here, since Other's contribution was what got me to complete my repair. The car's showing noticeable improvement, yet still further improvement is pending since I have to replace rear engine mounting and the rubber washers on the bolts holding the engine cross member.

the bolts are expected to be 'high tensile' supporting higher rating of newtons of force. but galavanised bolts would suffice. Especially after seeing others have replaced these using stainless steel ones which are believed to be of less strength. I bought SS ones but then replaced them with galvanised ones bought directly from Wuerth Agent since these had half threaded and half plain for the bush to rest on.

the bolts are expected to be 'high tensile' supporting higher rating of newtons of force. but galavanised bolts would suffice. Especially after seeing others have replaced these using stainless steel ones which are believed to be of less strength. I bought SS ones but then replaced them with galvanised ones bought directly from Wuerth Agent since these had half threaded and half plain for the bush to rest on.

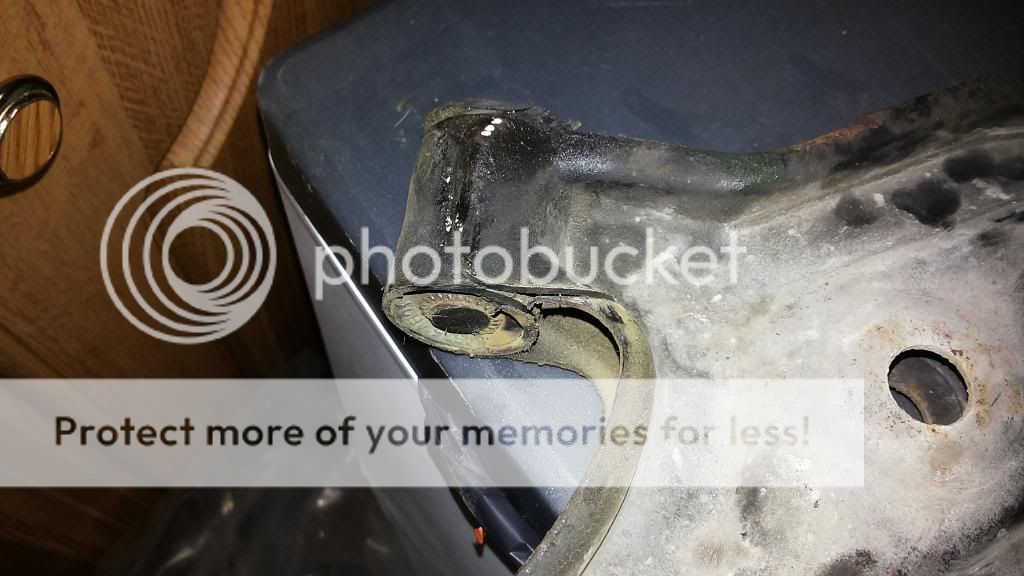

Went to fit the bushes to find that the size required for Nissan and newly purchased (from ebay or a motor-factors) wishbones is different. It seems that the wishbone is the same, but when making the front bush, nissan set the rubber in the wishbone, but new wishbones have a bush with separate metal case pressed in (creating a double thickness of tube). I also found that the front bush case on my original nissan wishbone had deformed, I didnt take a picture of mine but i can see that funky2nite's has done the same, you can see how the tube has stretched here:

anyway, so in case it helps people working on their wishbones, here is how i did it.

First you have to remove the split-pin and clean the thread on the ball joint, I used a thin wire bush. Then spray on a load of WD40 and loosen off the nut. I like to run the nut up and down the thread a few times till its easy.

Before clean:

After:

Now, one way to split the ball joint off is to place a spanner between nut and CV joint, then wind the nut up onto the spanner which should pop the joint out, like this

Otherwise, hitting the bottom of the hub where the ball joint is fixed to with a large hammer will usually make the joint drop out.

Once the joint is poped free, you will have to remove the nut (no space to remove it before joint is out), any resistance in the nut coming off because of gunked up thread will meant hat the ball joint just spins in its housing, if this happens then a jack under the ball joing will temporarily press it back into the hub and stop is spinning

Now remove the anti roll bar droplink (if you have one). (sorry, no pic but its pretty obvious).

And front and rear bush mounts (my front bolt came out pretty easy (not sure if its because i was using a rattle gun?) otherwise you will have to cut the bolt like funky2nite did (but try not to cut into the wishbone if you plan on keeping it eh).

Rear:

Front:

Now, I burnt out the front bush with a blowtorch, bit smelly but easy and quick.

This is when I realised the size difference so I made a new bush the right size (front bush) and fitted them I did some gentle massage of the front bush tube to make it more tube like. It is clear though that this is a weak point in the Nissan wishbone, I think the double thickness mortor-factor ones will serve better in this area.

I did some gentle massage of the front bush tube to make it more tube like. It is clear though that this is a weak point in the Nissan wishbone, I think the double thickness mortor-factor ones will serve better in this area.

I also made a mould for the droplink bushes but had no time to make and fit them

All in all, with the bolt coming out easy (and if I didnt have to make a new bush), The job would have taken maybe 45mins - 1 hour per side (maybe 5 mins for frank).

(maybe 5 mins for frank).

I wouldnt even try working on wishbones without a nice big can of lube though.

Edit: I meant to add, I suggest that people grease up the rear bush (between wishbone and bush)! this gets really stuck and I was told by a rally guy that this can lead to torsional fatigue failure.

anyway, so in case it helps people working on their wishbones, here is how i did it.

First you have to remove the split-pin and clean the thread on the ball joint, I used a thin wire bush. Then spray on a load of WD40 and loosen off the nut. I like to run the nut up and down the thread a few times till its easy.

Before clean:

After:

Now, one way to split the ball joint off is to place a spanner between nut and CV joint, then wind the nut up onto the spanner which should pop the joint out, like this

Otherwise, hitting the bottom of the hub where the ball joint is fixed to with a large hammer will usually make the joint drop out.

Once the joint is poped free, you will have to remove the nut (no space to remove it before joint is out), any resistance in the nut coming off because of gunked up thread will meant hat the ball joint just spins in its housing, if this happens then a jack under the ball joing will temporarily press it back into the hub and stop is spinning

Now remove the anti roll bar droplink (if you have one). (sorry, no pic but its pretty obvious).

And front and rear bush mounts (my front bolt came out pretty easy (not sure if its because i was using a rattle gun?) otherwise you will have to cut the bolt like funky2nite did (but try not to cut into the wishbone if you plan on keeping it eh).

Rear:

Front:

Now, I burnt out the front bush with a blowtorch, bit smelly but easy and quick.

This is when I realised the size difference so I made a new bush the right size (front bush) and fitted them

I also made a mould for the droplink bushes but had no time to make and fit them

All in all, with the bolt coming out easy (and if I didnt have to make a new bush), The job would have taken maybe 45mins - 1 hour per side

I wouldnt even try working on wishbones without a nice big can of lube though.

Edit: I meant to add, I suggest that people grease up the rear bush (between wishbone and bush)! this gets really stuck and I was told by a rally guy that this can lead to torsional fatigue failure.

Attachments

Thanks for that bud looks good, my only problem is where you are saying they have a weak point, changing the bushes do you prise open the wishbone or knock them out and if so will this not make them even weaker (just thinking the grasser will put quite a bit of load on these) now debating which would be best for me

You just burn out the old rubber bush mate. no damage to the metal.Thanks for that bud looks good, my only problem is where you are saying they have a weak point, changing the bushes do you prise open the wishbone or knock them out and if so will this not make them even weaker (just thinking the grasser will put quite a bit of load on these) now debating which would be best for me

You just burn out the old rubber bush mate. no damage to the metal.

Ahh so the rubber goes all way through with you now, Gonna get them off at weekend and have a good look will get back to ya Noddie cheers again

Ahh so the rubber goes all way through with you now, Gonna get them off at weekend and have a good look will get back to ya Noddie cheers again

Its the bushes which have gone right?

Make sure you check the ball joint also, its thats knackered then complete replacement wishbones are pretty cheap off Ebay (obviousely they are supplied with rubber bushes but if poly isnt important to you then they are far easier than trying to replace just the ball joint).

pollyp

Club Member

when I upgraded to poly bushes, I drilled round the rubber on mine to remove the inner insert and then slotted the outer insert with a saw to release it

http://micra.org.uk/threads/pollymobiles-rebuild.35251/page-50#post-509593

http://micra.org.uk/threads/pollymobiles-rebuild.35251/page-50#post-509593

h701micra

Deactivated Account

Got a spare set you can test on the k10 arms?I have made poly bushes which will fit inside the second metal sleeve = easier and leaving in extra strength to stop the metal deforming as above.

Its the bushes which have gone right?

Make sure you check the ball joint also, its thats knackered then complete replacement wishbones are pretty cheap off Ebay (obviousely they are supplied with rubber bushes but if poly isnt important to you then they are far easier than trying to replace just the ball joint).

Its not gone to be honest just wanted to replace the drivers side wishbone and all other parts on the grasser due to a bit of camber on that wheel after having a bump at the back end of the season. Just looks like the easiest/only way to get them off is with the trusty grinder

Its not gone to be honest just wanted to replace the drivers side wishbone and all other parts on the grasser due to a bit of camber on that wheel after having a bump at the back end of the season. Just looks like the easiest/only way to get them off is with the trusty grinder

As I said, mine did come out without any trouble so you might be lucky

not replacing with new ones they are just off the donor car bud, at the mo I'm trying to take them off the donor bud to no avail. Replacing them because i couldn't get rid of camber after a wee bang on the drivers side so wanted to replace the lot to be sure

Ok on stripping the front end today i noticed the replacement front strut i put on was quite loose on the top nut, so now I'm thinking this is why i still had the camber on that wheel gonna sort that out first and see, as always guys thanks for the help will get back to ya

funky2nite

Ex. Club Member

Noticeable difference is evident, yet much is still to be desired with regards to ride quality I am still getting loads of bumps being felt inside the cabin even till the steering. I'm sure the 195/65/15 wheels are playing a crucial role but I recall the ride never being this rough b4..