Shaun

***StaGGeRed***

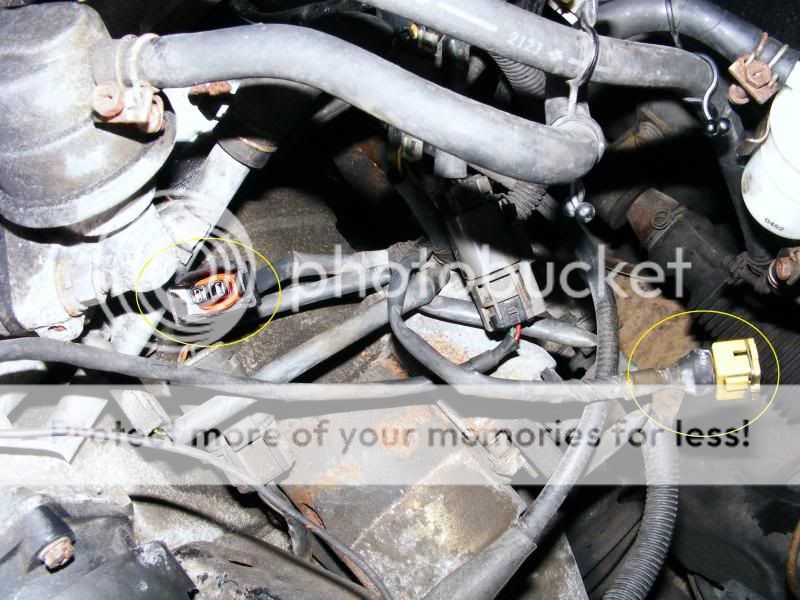

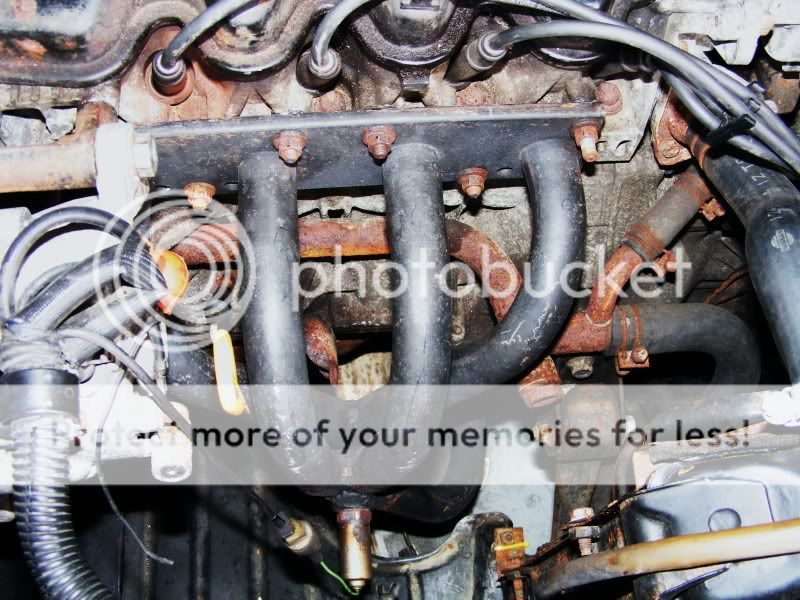

Ok so removed the EGR system over the weekend with the help of mckenziecz and to our suprise it was quite simple and quick. however we are now left with some odd ends that the guide on the forum does not show  any help would be appreciated.

any help would be appreciated.

and yes the engine bay is still rusty

thankyou!!

and yes the engine bay is still rusty

thankyou!!