Hello all,

I posted an introduction in the general section. I hope not being from the UK that my membership will be acceptable?

So I have a K12 that I have been playing around with for some time. It was bought as a 2003 JDM used import with 25,000km on it. I drove it home and basically jacked it up and went to work.

As of now, it has been modified quite a bit, and more to come.

I got it with a Nissan Body Ki and Fog Lights. It also came with a NISMO front and rear suspension as well as a full HKS exhaust system (that was actually shown in the Japanese owners manual).

So here is what I did:

Out with 1400cc motor and Auto Tranny

Out with the rear Drum Brakes

Out with the front Disk Brakes

Out with the exhaust

Junked the Instrument Cluster

Remved the giant brake pedal

Removed the Accelerator assembly

Removed the Auto Shifter assembly

Removed ECM and SMJ

Installed 12in two piece Wilwood Rotors and 4 piston Calipers on the front with some custom brackets and braided lines. ABS still works.

Installed rear disk brakes from a B13 model Nissan Sunny. Using the OEM rear hubs with bit of machining...........braided lines as well.

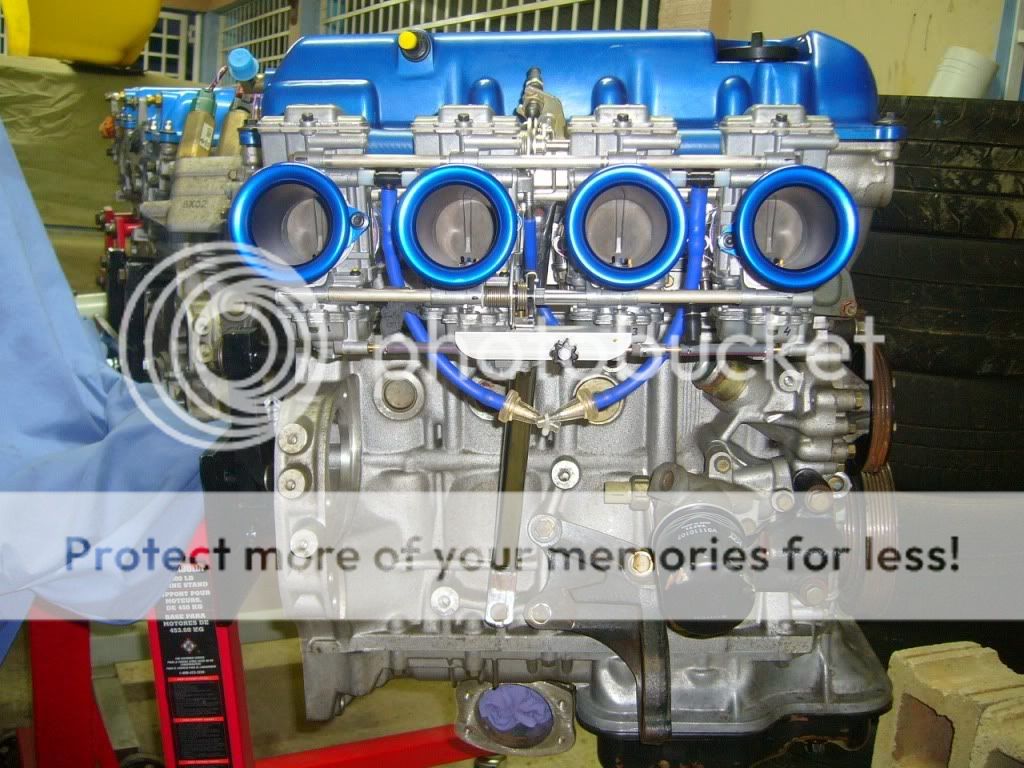

Installed a Nissan 1.6 SR16 NEO VVL motor with N1 Cams. No fuel injection......side draft Keihin FCR-H carbs.

Installed Titanium retainers.

Installed a 4 Fogger Nitrous system rom NOS.

NOS activated by Greddy MSS.

OEM pump feeds the carbs via a Holley Regulator, Holley Pump feeds the Nitrous.

Ignition is an Electromotive wasted spark system.

Gear Box is SR16 NEO VVL with LSD...........custom made axles.

All engine brackets botl back to OEM points, no welding on chassis.

AIM MXL Data Logger.

Custom made shifter linkage.

Custom made hydraulic clutch pedal using the OEM clutch pedal (sourced from Ireland) as a foundation.

Wilwood Clutch Slave Cylinder.

Remote Oil Filter and braided lines through a 9 row Earls Oil Cooler.

I had to completely re-wire the Engine Bay as a result of removing the SMJ and ECM. This included jumper wiring the IPDM so that the system still operated as normal with no problems to the rest of the onboard computers, relays etc.

Car is on 17in SSW Wheels with 205/45/17 Dunlop Tyres.

After tuning the motor made 155bhp on the motor only, measured at the wheels on a Dyno Dynamics eddy Current Rolling Road.

With NOS it makes 220bhp at the wheels.

Best time is a 13.2 second 1/4 mile with a 2.1 second 60ft, running 22in slicks.

Here are a few pictures:

I hope you like.

I posted an introduction in the general section. I hope not being from the UK that my membership will be acceptable?

So I have a K12 that I have been playing around with for some time. It was bought as a 2003 JDM used import with 25,000km on it. I drove it home and basically jacked it up and went to work.

As of now, it has been modified quite a bit, and more to come.

I got it with a Nissan Body Ki and Fog Lights. It also came with a NISMO front and rear suspension as well as a full HKS exhaust system (that was actually shown in the Japanese owners manual).

So here is what I did:

Out with 1400cc motor and Auto Tranny

Out with the rear Drum Brakes

Out with the front Disk Brakes

Out with the exhaust

Junked the Instrument Cluster

Remved the giant brake pedal

Removed the Accelerator assembly

Removed the Auto Shifter assembly

Removed ECM and SMJ

Installed 12in two piece Wilwood Rotors and 4 piston Calipers on the front with some custom brackets and braided lines. ABS still works.

Installed rear disk brakes from a B13 model Nissan Sunny. Using the OEM rear hubs with bit of machining...........braided lines as well.

Installed a Nissan 1.6 SR16 NEO VVL motor with N1 Cams. No fuel injection......side draft Keihin FCR-H carbs.

Installed Titanium retainers.

Installed a 4 Fogger Nitrous system rom NOS.

NOS activated by Greddy MSS.

OEM pump feeds the carbs via a Holley Regulator, Holley Pump feeds the Nitrous.

Ignition is an Electromotive wasted spark system.

Gear Box is SR16 NEO VVL with LSD...........custom made axles.

All engine brackets botl back to OEM points, no welding on chassis.

AIM MXL Data Logger.

Custom made shifter linkage.

Custom made hydraulic clutch pedal using the OEM clutch pedal (sourced from Ireland) as a foundation.

Wilwood Clutch Slave Cylinder.

Remote Oil Filter and braided lines through a 9 row Earls Oil Cooler.

I had to completely re-wire the Engine Bay as a result of removing the SMJ and ECM. This included jumper wiring the IPDM so that the system still operated as normal with no problems to the rest of the onboard computers, relays etc.

Car is on 17in SSW Wheels with 205/45/17 Dunlop Tyres.

After tuning the motor made 155bhp on the motor only, measured at the wheels on a Dyno Dynamics eddy Current Rolling Road.

With NOS it makes 220bhp at the wheels.

Best time is a 13.2 second 1/4 mile with a 2.1 second 60ft, running 22in slicks.

Here are a few pictures:

I hope you like.