I did a Peugeot 206 one for my Mini engine conversion.

It wasn't easy!

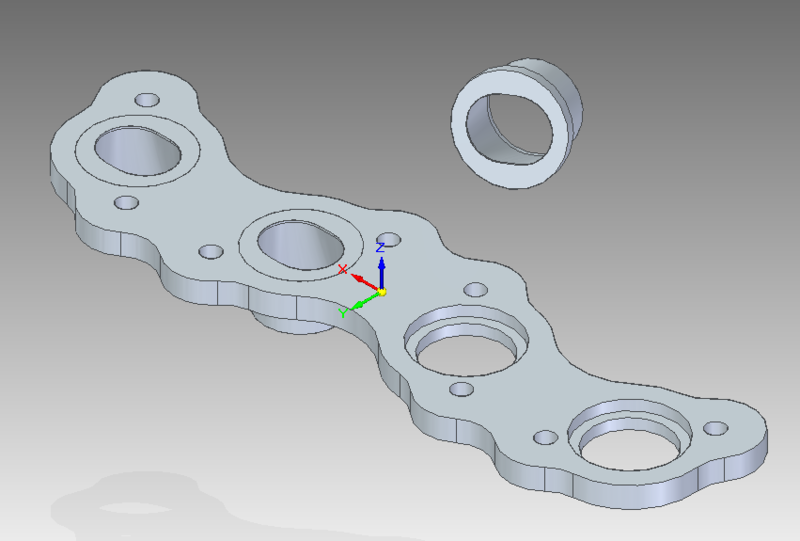

I CAD modeled a flange and transition bungs to change the oval port to round.

Cut the old flange off.

Cut a slot at both Y junctions and bent the branches until they fitted over the bungs.

A lot of tacking, checking and then welding. My new flange was like a banana when I had finished so I had to straighten it on the press.

A VW Polo one is also a contender. I used the 206 one as I scored it on eBay for a decent price.

My TIG welding has fairly improved by doing this. Still could do with improvement.